I understand why they sell an under bed mower for the thing. But I'm going to find a 54" cat-1 I can drag around instead.I had one come off mine, but thankfully didn't do any big damage, just wrecked a pair of boxers. I gave it a tug and everything (the pto shaft...), was 100% sure it was seated on the detent. Have no idea how it came off.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What's Paul up to?

- Thread starter PaulL

- Start date

The 3 point mower still has a pto shaft, needs to be rite length, or other "new" problems. The coupler with the slide collar can be a major pain, I think the pin type is better, anything that rubs length wish on the collar type can unlatch it.

Maybe need a guard around the oil filter, I know 1 more thing to deal with when changing filter!

Maybe need a guard around the oil filter, I know 1 more thing to deal with when changing filter!

Well fsck.

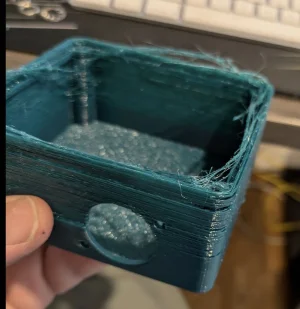

My last print came out like this:

Filament feed looks to be weak. Tried some cleaning, running some nylon, a dry pull. No joy.

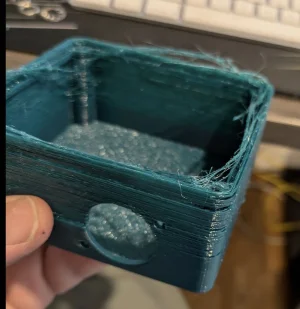

So I set the thing to maximum heat to change the nozzle. Here's half the nozzle plasticized into my 7mm socket:

Freaking mess. Letting it sit for a while before diassembling the head and figuring out what to do.

My last print came out like this:

Filament feed looks to be weak. Tried some cleaning, running some nylon, a dry pull. No joy.

So I set the thing to maximum heat to change the nozzle. Here's half the nozzle plasticized into my 7mm socket:

Freaking mess. Letting it sit for a while before diassembling the head and figuring out what to do.

Yeah. Ordered a new hot end and sensors and heat break. Have to disassemble back far enough to redo the wiring harness but this seems to be the best way to get up and running again.Ugh. That doesn’t look like it’s going to be very fun to fix.

What

I forget what kind of printer you have now.Yeah. Ordered a new hot end and sensors and heat break. Have to disassemble back far enough to redo the wiring harness but this seems to be the best way to get up and running again.

Those are exactly what I ordered. Should be here today. I'll remember your kind offer.I have parts like this here if that would help. They are old school so to speak.

View attachment 49119

No update on the printer. Parts are here but I need a rainy day before I commit to tearing it down far enough to put them in place.

Meanwhile, I've been in the "hot" shop. I finally got the acorn table over there:

Crane guy was quite accommodating, and was able to unload directly onto the landing craft I booked for the crossing. He even managed to load the lathe straight into the utility trailer I already had on the landing craft. Then a nice neighbor with a telehandler moved the table down to where I could roll into the shop on the casters I put on long ago. It's now in place, sitting on blocks instead of casters, and making itself useful. Still need to figure out how I'll attach the vise.

I needed a little adjustable jack for holding bars at the anvil, so I made this simple thing. Though I particularly like the little feet. I'm now going to do a bunch of little feet studies, because I realize how much further I can take these.

Lastly, I'll tease with the lathe in place, and not mention the "win stupid prizes" part of the move.

More on the lathe in a few days as I finish getting the motor in place and get to first chips.

Paul

Meanwhile, I've been in the "hot" shop. I finally got the acorn table over there:

Crane guy was quite accommodating, and was able to unload directly onto the landing craft I booked for the crossing. He even managed to load the lathe straight into the utility trailer I already had on the landing craft. Then a nice neighbor with a telehandler moved the table down to where I could roll into the shop on the casters I put on long ago. It's now in place, sitting on blocks instead of casters, and making itself useful. Still need to figure out how I'll attach the vise.

I needed a little adjustable jack for holding bars at the anvil, so I made this simple thing. Though I particularly like the little feet. I'm now going to do a bunch of little feet studies, because I realize how much further I can take these.

Lastly, I'll tease with the lathe in place, and not mention the "win stupid prizes" part of the move.

More on the lathe in a few days as I finish getting the motor in place and get to first chips.

Paul

I like the "little feet" as well, careful Mom doesn't come out and paint the toenails. lol

Lemme guess, the boom was retracted and the legs of the crane hit the wall leaving the lathe short of the bench.not mention the "win stupid prizes" part of the move

Dumber. Had the lathe in the utility trailer, slung under my loader. At full extension couldn't clear the edge. Instead of re-slinging it I drove the trailer out from under it. Which demonstrated my lack of rotational constraint. Flipped right over. No injury, no damage, but a hell of a time getting it back upright. And I'm much more careful now.I like the "little feet" as well, careful Mom doesn't come out and paint the toenails. lol

Lemme guess, the boom was retracted and the legs of the crane hit the wall leaving the lathe short of the bench.

Sorry Paul, I should have told you that the Clausing is super top heavy. I had to close the chuck jaws around the lifting strap to keep it from flipping over when loading it solo.Dumber. Had the lathe in the utility trailer, slung under my loader. At full extension couldn't clear the edge. Instead of re-slinging it I drove the trailer out from under it. Which demonstrated my lack of rotational constraint. Flipped right over. No injury, no damage, but a hell of a time getting it back upright. And I'm much more careful now.

First chips! A real part!

My power hammer threw a top die loose. The retaining pin wasn't there! I didn't even know there was supposed to be one. But I did find the slot in the die, and the receiver in the ram, and the matching pin in bottom die, so I made the same part and it fits just fine.

So fewer exciting times ahead, and I didn't have to wait until I got back to the city shop to make it up. Achievement unlocked!

My power hammer threw a top die loose. The retaining pin wasn't there! I didn't even know there was supposed to be one. But I did find the slot in the die, and the receiver in the ram, and the matching pin in bottom die, so I made the same part and it fits just fine.

So fewer exciting times ahead, and I didn't have to wait until I got back to the city shop to make it up. Achievement unlocked!

And related, but separate, I got a decent pair of pickup tongs made for use under the hammer:

It feels like I've finally rounded the corner on some "making cleaner forgings" issues that have been plaguing me for years - mostly due to not enough practice. These days I've been managing 9:00-12:00 in the forge daily, and after a couple of weeks it's really starting to show.

Another example: these little tongs for holding letter stamps. I should have done this long ago.

It feels like I've finally rounded the corner on some "making cleaner forgings" issues that have been plaguing me for years - mostly due to not enough practice. These days I've been managing 9:00-12:00 in the forge daily, and after a couple of weeks it's really starting to show.

Another example: these little tongs for holding letter stamps. I should have done this long ago.

This took *ridiculously* more effort than it should have.

The post is anchored in a welded up bracket on the floor (which I forgot to photograph...let's just say I'm not a star at fabrication), and bolted to the middle girt of the shop.

The engine hoist got it up hight enough in the air, but couldn't come close enough to the wall so a ratchet strap anchored to the top of the post swung it into place long enough to get the 4" lags in.

It needs a lot of work. And two parts seem to have gone missing, probably from when I bought it: the crank and bevel gear to raise and lower the table, which was clearly removed to make moving this easier - the retaining bolts for it are loose in their tapped receivers, and the bottom bracket for the table, which is why the table isn't mounted.

The bottom bracket is easy - I'll probably get that together when I'm back in the shop on Monday. The crank is harder. I think I'll knock on the seller's door and see if it wound up in a pile somewhere. Wish I'd noticed a year ago :-(. Otherwise it will be an interesting machining project to reproduce something to mesh with the existing gear.

The post is anchored in a welded up bracket on the floor (which I forgot to photograph...let's just say I'm not a star at fabrication), and bolted to the middle girt of the shop.

The engine hoist got it up hight enough in the air, but couldn't come close enough to the wall so a ratchet strap anchored to the top of the post swung it into place long enough to get the 4" lags in.

It needs a lot of work. And two parts seem to have gone missing, probably from when I bought it: the crank and bevel gear to raise and lower the table, which was clearly removed to make moving this easier - the retaining bolts for it are loose in their tapped receivers, and the bottom bracket for the table, which is why the table isn't mounted.

The bottom bracket is easy - I'll probably get that together when I'm back in the shop on Monday. The crank is harder. I think I'll knock on the seller's door and see if it wound up in a pile somewhere. Wish I'd noticed a year ago :-(. Otherwise it will be an interesting machining project to reproduce something to mesh with the existing gear.

Get the lineshaft running. Even if you don't use it that's a wicked piece of art.

Is this the same machine?

Is this the same machine?

The very same one. But this one has some after market modifications that I'm trying to figure out if I want to unroll.Get the lineshaft running. Even if you don't use it that's a wicked piece of art.

Is this the same machine?

A bit more shop time. A chasing hammer for my sweetie, who wants to get into repousse work.

First a punch and a drift, out of some Atlantic 33 that arrived last week. To date I *really* like the "do nothing" tempering routine. Though the quench temperatures are *high*. I did the face with an oxy-propane torch to isolate the heat and just wailed on it until it upset to the right shape. Managed just about 1 1/4" out of the 3/4" base stock. And the hammer is out of the A-33 as well. We'll let you know how it holds up.

And it's not done if it doesn't have a handle. This is some locally-harvested yew a neighbor had in his firewood pile (gasp!).

It split beautifully, and the drawknife work was like putting on an old glove. It's been a long time, but still seems to work.

For next time, I'll probably move the eye 3/16ths towards the peen end - the balance isn't bad, but the visuals are a bit off.

First a punch and a drift, out of some Atlantic 33 that arrived last week. To date I *really* like the "do nothing" tempering routine. Though the quench temperatures are *high*. I did the face with an oxy-propane torch to isolate the heat and just wailed on it until it upset to the right shape. Managed just about 1 1/4" out of the 3/4" base stock. And the hammer is out of the A-33 as well. We'll let you know how it holds up.

And it's not done if it doesn't have a handle. This is some locally-harvested yew a neighbor had in his firewood pile (gasp!).

It split beautifully, and the drawknife work was like putting on an old glove. It's been a long time, but still seems to work.

For next time, I'll probably move the eye 3/16ths towards the peen end - the balance isn't bad, but the visuals are a bit off.