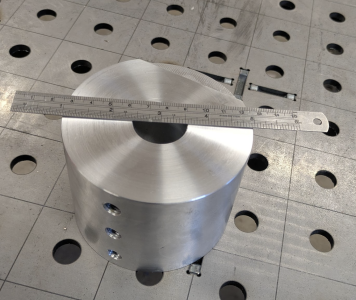

I've been doing more work on the bandsaw. Now that I have a 5HP motor, I needed a pulley.

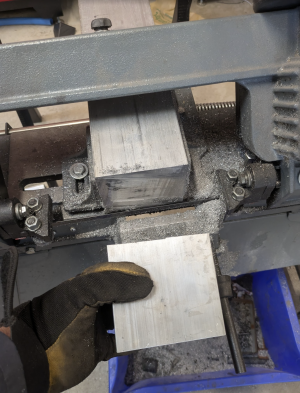

Fortunately I had this bar of 6061 hanging around that I picked upon speculation some time ago:

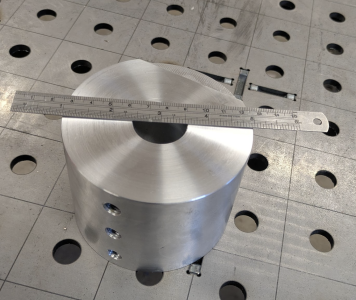

Then a 4-jaw face-off:

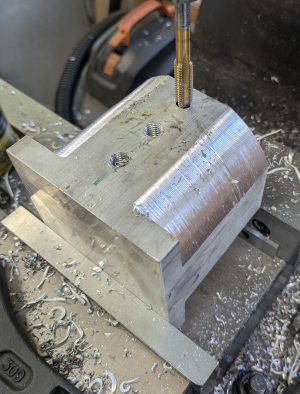

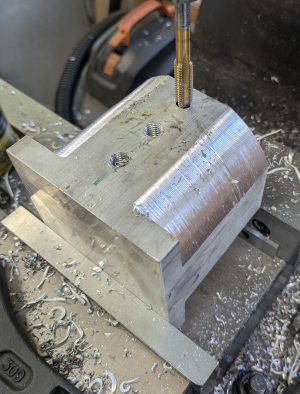

And before losing my starting faces, which are square enough for my purposes, I dropped in a set of tapped holes to drop some square-ended set screws to engage the keyway in the motor shaft.

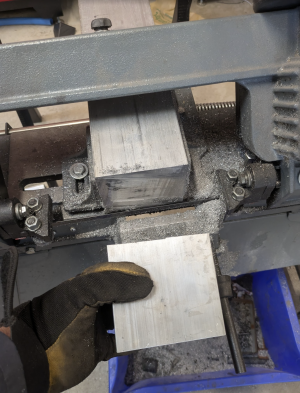

I added some indexing faces so I could drop the pulley on a set of narrow parallels in a vice. These are exactly opposite and perpendicular to the tapped holes in case I decide I want to remachine the holes or set it up in a shaper for a real keyway.

For now this will do to get a belt length measurement off to Jack Forsberg to make me up a flat belt. I'll post some pics of the final setup when I get the saw going!

Fortunately I had this bar of 6061 hanging around that I picked upon speculation some time ago:

Then a 4-jaw face-off:

And before losing my starting faces, which are square enough for my purposes, I dropped in a set of tapped holes to drop some square-ended set screws to engage the keyway in the motor shaft.

I added some indexing faces so I could drop the pulley on a set of narrow parallels in a vice. These are exactly opposite and perpendicular to the tapped holes in case I decide I want to remachine the holes or set it up in a shaper for a real keyway.

For now this will do to get a belt length measurement off to Jack Forsberg to make me up a flat belt. I'll post some pics of the final setup when I get the saw going!