Just back from a few heavy rain days at the cabin. Got the irrigation systems shut down. Why does irrigation work always wind up with me soaked?

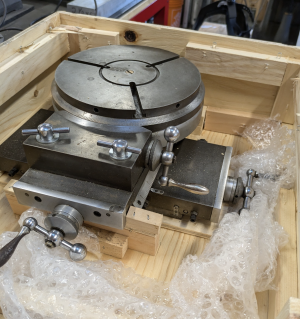

And when I got back, a heavy but small wooden crate was awaiting me:

She's a beaut. All three axes are buttery-smooth. Also has an interesting gear-engaging mechanism where the block housing the lead screw swings out:

I haven't figured out any locking mechanism for the rotary axis, however.

No commercial marks on it, and it could all have been done in-shop. Came to me from Nova Scotia.

Paul

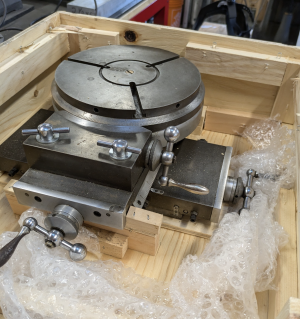

And when I got back, a heavy but small wooden crate was awaiting me:

She's a beaut. All three axes are buttery-smooth. Also has an interesting gear-engaging mechanism where the block housing the lead screw swings out:

I haven't figured out any locking mechanism for the rotary axis, however.

No commercial marks on it, and it could all have been done in-shop. Came to me from Nova Scotia.

Paul