trlvn

Ultra Member

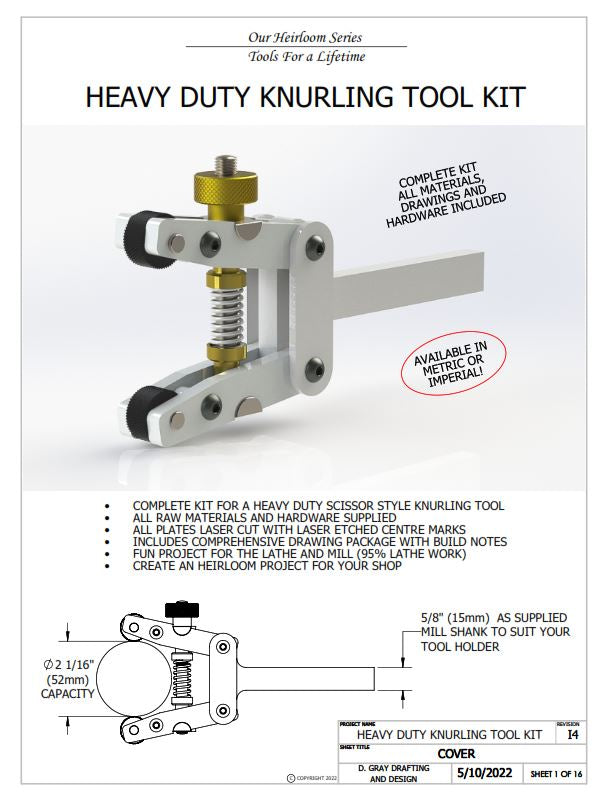

@Susquatch : I have plans coming from England to build this:

View attachment 24753

I will be taking the left hand unit you show and chopping it up for use as the mounting arrangement and re-purposing the wheels for the unit itself. I also have a couple sets of straight wheels that will go into play. I will, of course, be posting the results of this build.

It is a Hemingway Kits model. - I just ordered the plans - not the materials

Hi Brent:

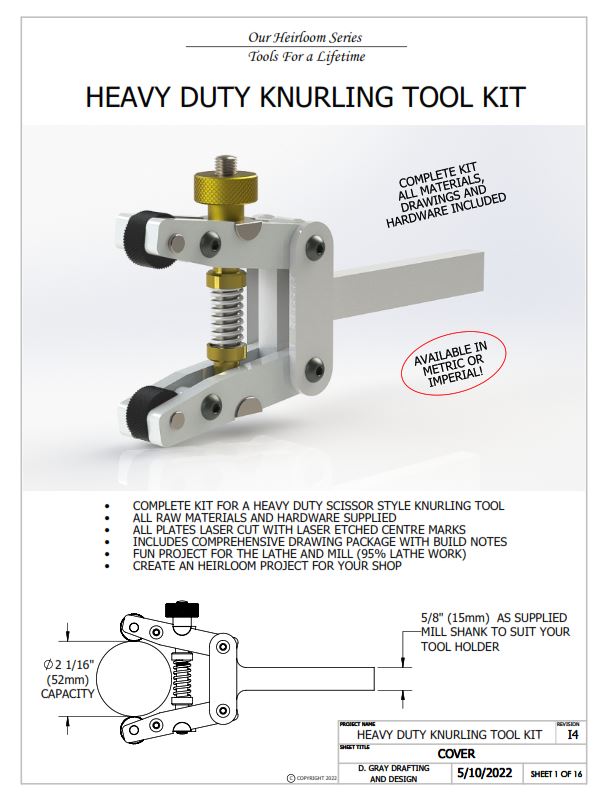

I'm curious if you looked at Doug Gray's plans/kit:

Heavy Duty Knurling Tool Drawings Only

Heavy Duty Knurling Tool Kit Drawings Only The drawings only version of this product is a pdf digital download of the complete 16 page drawing package that include building notes and full scale templates of the plates. An immediate digital download so no waiting or postage. Fantastic...

d-gray-drafting-and-design.myshopify.com

If you compared them, what led you to choose the Hemingway?

Craig