I've been purchasing metric screws (Black oxide; hex socket) from MMC for years and I have a substantial inventory. Their screws are significantly harder than the offshore cheapies. But the main reason I keep using MMC is that their products are consistent and I can rely on them for the same quality over many years of orders.I've been making up a list at AliExpress since I need 32 different screw types. I think I will finish the spreadsheet of all the screws and get Spaenaur to quote but for this cheap (well not really cheap) robot arm I'm not sure I need an extra 87 screws if I have to buy a box of 100.

Even McMaster Carr can supply these of which I need 13 according to the parts list.

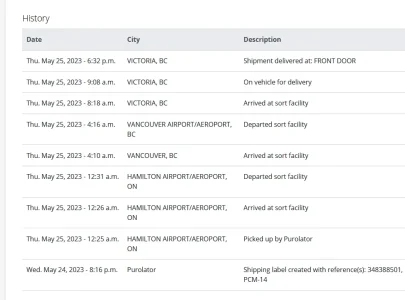

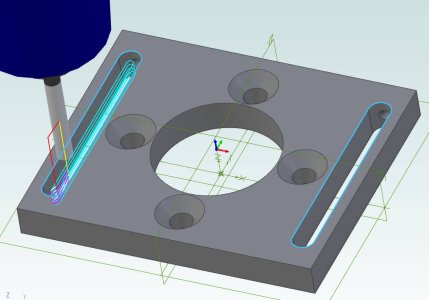

View attachment 34830

Where AliExpress wants 1/2 of that but of course I'll have to probably wait a month where McMaster Carr will ship on Friday.

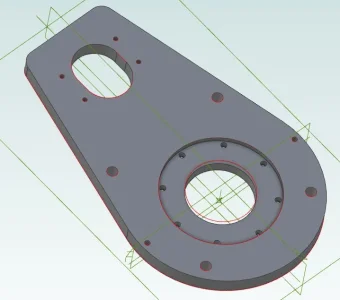

View attachment 34831

I wonder if the quality is any different. Shipping is about $25 from McMaster Carr.

If you only need a few dozen screws John, just DM me.

Don