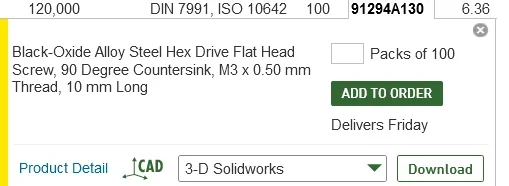

Here's an update on the incorrect XL pulleys. I only needed on 15T XL series. But they came in pairs from AliExpress reseller. For $5 or so including shipping. However they had the curved tooth profile for the metric pulleys. Even though the web site and the order said XL series. Pitch is 5.08mm rather than 5mm.

Now you'd think that probably wouldn't be a problem but it turns out there's a fair amount of slop between the XL belt and the metric pulley. Well today two XL 15T pulleys from a different supplier arrived. I held my breath hoping that it wasn't another identical screw-up.

Nope. They are beautiful. Also only about $5 for the two.

View attachment 32942

Also in the same package (AliExpress have been combining packages to save on local shipping) I received the 3mm OD x 1mm ID silicon tubing and both fast attach couplers and ones with nibbles to slide the tubing onto. The tubing is too software for the fast attach. However the other ones are great. Tubing slides onto the nipple and then the knurled nut threads on and compresses against the tubing to hold it tight. As it is it's hard to remove again anyway.

The other end of the tubing will go to a little adaptor manifold I have to make to upsize to the standard 1/4" tubing for the valve. That's 3mm threaded to 1/4" pipe thread.

View attachment 32943

Unfortunately a work-work project surfaced and I'll be busy for quite some time before I can continue with this project.

🙁