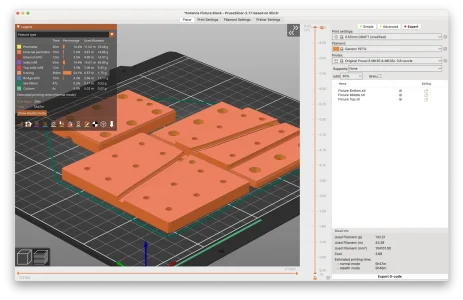

Yes to both (at least with Prusa's slicer), but with provisos.- Can you change the orientation of the model within the printing software, or does the model have to be made in the best orientation for printing?

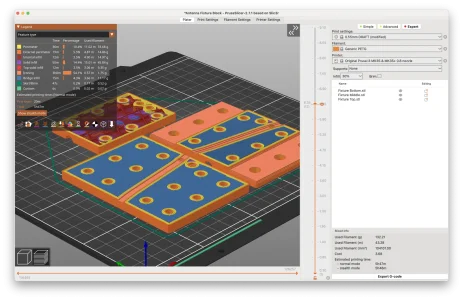

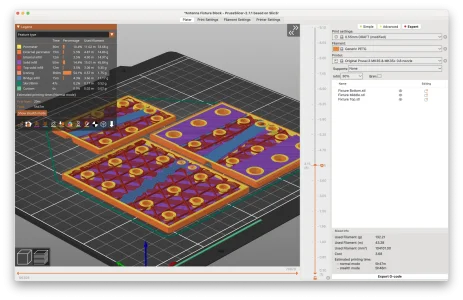

- Does the printing software automatically generate the necessary supports for things like undercuts, or are they manually added?

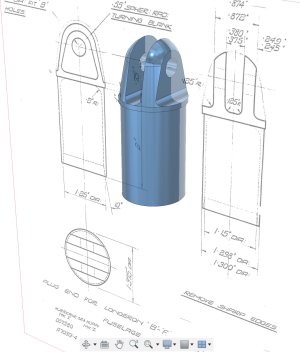

1. You can change the orientation in the slicer, but if there's not already a "good" orientation in the part, you're up the creek. I went a put a small wiper ridge on one edge of a recent DRO bracket, and that, of course, blocked laying it down on that side, forcing a different orientation. Not catastrophic, but annoying to have a tall part to print instead of a nice flat one.

2. It can, though it tends to be pretty aggressive when you ask it to. You can paint on supports in the slicer and it will figure out how to support just those sections. It's also impressive how much empty air the LDM process can span with some materials, and how steep an overhang is possible before sagging starts.