@Perry yes I meant clean with IPA. no wait a second. I'm sure that's a brew... yes that's it. Clean bed with beer then wipe with woven cloth.

😀🙄 no no no...

My take so far on the Prusa vs Bambu. but i've only had the bambu for a few days.

Bambu

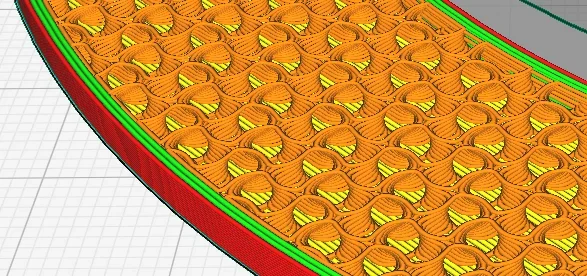

+ inexpensive and has shipping AMS options. fast with their settings and PLA. PETG performance is similar to existing printers (slower).

+ Great software for starting/controlling/monitoring prints. Slice, and in the slicer hit print. Job runs. Easy easy & convenient. Phone can monitor. Phone beeps when done. onboard camera works on web and phone to keep an eye on it.

+shipping - Printer showed up before they said it would.

- slicer software seems fussier to me, and is not as powerful as Prusa Slicer. Text control is better on prusa and other features.

- AMS wastes a lot of filament and takes a while to switch.

- prints take a while or forever to start printing - it's not as fast they claim due to the preprocessing. depends on settings you choose too.

Prusa

+... long term printer reliability is proven and good.

+ Slicer is generally better.

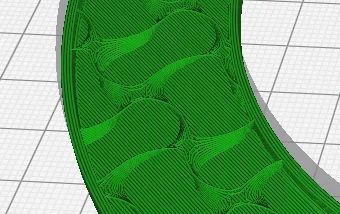

+ great prints. all the time unless there are operator errors. poor cleaning. wet filament. incorrect settings, calibration, the details. my fault in other words.

+ AMS implementation seems like it will be better, faster, less wasteful, but I haven't seen it.

- Ordered a AMS in ... June? long time back. no ETA keeps getting delayed.

- work flow to get a file out, uploaded to the printer, and actually get it printing is about a 15 separate little steps. It's aggravating especially with one or 2 click go on the bambu.

+ software releases make the printer better and better. the work flow to get a file over wifi was unusable, then they made it usable. It could be a lot more convenient and I'm sure they will address it. eventually.

- pricey

+ supporting manufacturing outside of, well you know, where everything is made.