BaitMaster

Ultra Member

Hi my name is BaitMaster and it has be 0 days since I’ve used my 3D printer, and I am an addict.

Hey Obi Wan...... Beware of the dude in black, he's got a mean light saber...😉I am being very wary. But the force is strong...

Ohhhh that's a heck of a good idea for the 3,291 files I have without handles!Hi. My name is John. I'm a 3DPrintaholic and I just fell off the build table. Back to 0 days without using my 3D printer.

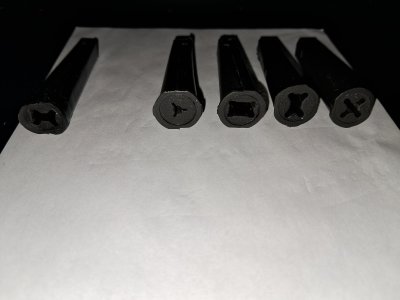

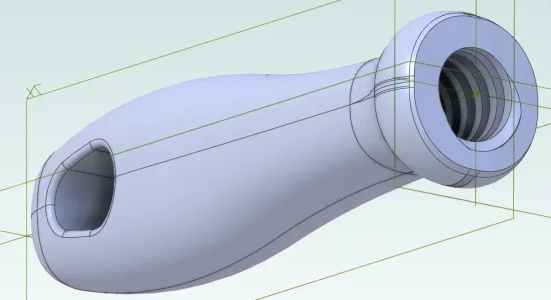

View attachment 43740

This was the 6" version. Any of the 6" files I have rattle loosely in it. The 8" ones are tight and don't go in all the way. However I suspect that if I heated the end to PLA melting temperatures I could push it in and let it lock on that way.Ohhhh that's a heck of a good idea for the 3,291 files I have without handles!

I had a few issues with some of my 10" files not fitting They were too loose. I needed to use the 8" modeled handles for them. They are all Nicholson files. but the tangs seem to be a little different in size. Is there a standard for the file tangs that could be referenced? I would like some of these handles for the round and triangle too.This was the 6" version. Any of the 6" files I have rattle loosely in it. The 8" ones are tight and don't go in all the way. However I suspect that if I heated the end to PLA melting temperatures I could push it in and let it lock on that way.

The 3 handles are all meant for flat files. The holes are the wrong shape for triangular or rat tail files.

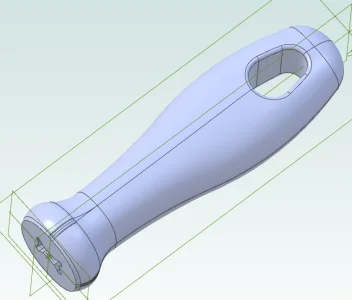

Just had to try it though. As the handles are all the same size except for the file tang hole I'm tempted to modify the step file to accept an insert. Maybe even one with coarse ACME threads like 4 TPI. Inserts would print a lot faster and one could have a larger selection for different file tang shapes.

I took the 10" step file and exported it as a rev 203 which is an older format? Exported in millimeters. See if you can import that.I had a few issues with some of my 10" files not fitting They were too loose. I needed to use the 8" modeled handles for them. They are all Nicholson files. but the tangs seem to be a little different in size. Is there a standard for the file tangs that could be referenced? I would like some of these handles for the round and triangle too.

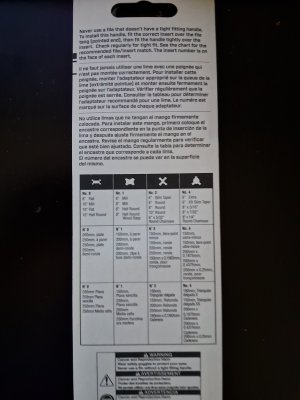

The person who designed these included the Solidworks model,but I can not open it. It is from a newer version. An insert set up like the genuine Crescent Nicholson ones would be a great.

First I need to find a reference for the tang sizes.

Thank you.I took the 10" step file and exported it as a rev 203 which is an older format? Exported in millimeters. See if you can import that.

Thank you.

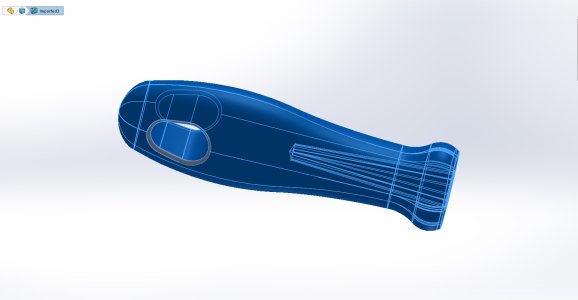

I can import the Step or the STL from the original files. Just not the Solidworks SLDPRT. I could also import your conversion.

I have to do the feature recognition and most likely a bit more work to get moving along.

I spent a little time looking researching tang dimensions this evening. No luck yet.

Need to finish up another little project first and I will get back to this. 🙂View attachment 43764

EDIT: Just thinking. Might be easier for me to head down to Lowes and purchase one of the Crescent Nicholson handles. They come with 4 inserts that I could grab the dimensions directly off of. 😉

Try this.You can import the SLDPRT with AlibreCAD. Interesting. Can you export it in "Parasolid" (*.x_t) format?

This might get me a step ahead.

Thank you. It worked the same as the STL and STEP. I though it would give me all the features.(As it top plane, front, and right.) That is ok. Still should be pretty easy to work with this.Try this.

The CAD people appear to be very reluctant to show the actual files they use to store the details. In fact Alibre is, how can I say it politely, so bad that they refuse to support older versions in their save as. So they can load an old version into newer software but cannot save from newer software as an older version. So once you save a file with say Rev 27 it cannot be loaded with Rev 25.yThank you. It worked the same as the STL and STEP. I though it would give me all the features.(As it top plane, front, and right.) That is ok. Still should be pretty easy to work with this.

Thank you John.

It imported with all of the operations and I can easily edit or modify them.The SLDPRT file is what I exported as .x_t. But it looks like importing it doesn't provide any extra information. It still comes in as one part.

Here's an Alibre AD_PRT file exported as .x_t and it does have a number of operations to create the part. So if you import this is it just one item like a STEP file or is it a bunch of operations to create the part.

It's possible that Alibre first converts it to the equivalent of a STEP file and then exports it in the appropriate format.

John, did you go any farther with this? It's the weekend and I might play with it a bit.Hmmm. Well that means either the imported solidworks file was treated like a STEP file or was in fact a STEP file, saved as solidworks file.

If someone is running solidworks and has a part that has a number of operations it would be interesting to see what Alibre does with that.

In either case one could still do this to it.

View attachment 43778