-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Parker Majestic refurb

- Thread starter David

- Start date

Also got this cool line drawing for the coolant pump.

It's a 3-phase pump so if I go the flood coolant route I have to get another VFD or setup a standalone system.

I'm thinking maybe a Fogbuster is a good route. Not keen on a mist system as I don't want the vapours hanging about... Happy to hear other perspectives.

It's a 3-phase pump so if I go the flood coolant route I have to get another VFD or setup a standalone system.

I'm thinking maybe a Fogbuster is a good route. Not keen on a mist system as I don't want the vapours hanging about... Happy to hear other perspectives.

Attachments

Update: the VFD for the grinder arrived today

I'm kind of curious about VFD retrofit motors for grinders for a project that wont leave my brain alone. Using your link, if I filter on approximate HP + 3-phase + general purpose, lots of candidates but all in the 1800 rpm range.

https://www.emotorsdirect.ca/search...al-Purpose&product-subsubcategory=Three~phase

When I click on any generic bench grinder, rpm is usually ~3500. I suspect related to target grinding SFPM at that wheel diameter

https://www.amazon.ca/King-Canada-K...d-search-10&pf_rd_t=BROWSE&pf_rd_i=7205691011

I know your application is probably different. Or maybe not, is it pulleyed up to achieve grinding rpm or is there some parameter I'm missing like KV?

Also for grinding applications, is there some parameter about the enclosure/breathing that makes it suitable for this kind of (potentially dirtier) duty?

There's no pulleys, it's direct drive.I'm kind of curious about VFD retrofit motors for grinders for a project that wont leave my brain alone. Using your link, if I filter on approximate HP + 3-phase + general purpose, lots of candidates but all in the 1800 rpm range.

https://www.emotorsdirect.ca/search...al-Purpose&product-subsubcategory=Three~phase

When I click on any generic bench grinder, rpm is usually ~3500. I suspect related to target grinding SFPM at that wheel diameter

https://www.amazon.ca/King-Canada-K...d-search-10&pf_rd_t=BROWSE&pf_rd_i=7205691011

I know your application is probably different. Or maybe not, is it pulleyed up to achieve grinding rpm or is there some parameter I'm missing like KV?

Also for grinding applications, is there some parameter about the enclosure/breathing that makes it suitable for this kind of (potentially dirtier) duty?

I've been told that a 1700 rpm motor can be run at 3400 rpm without issue.

For a grinding application I would only buy a TEFC - Totally Enclosed Fan Cooled motor.

That said, their filters don't seem to work 100% correctly. Send an email to them to ask. They are super helpful.

Last edited:

Fired up the P-M today. Definitely exciting because I hadn't seen it run because there was no power in the warehouse. Running off a Teco VFD.

There's more noise from the fan on the VFD than from the spindle.

Huge sigh of relief!

There's more noise from the fan on the VFD than from the spindle.

Huge sigh of relief!

Last edited:

very nice! great to see it working!

Thanks!

It’s a huge relief that it’s smooth and noise free.

Had a few moments today to work on the grinder.

There was a pretty good buildup of crud on the table handwheel so I took it off for cleaning. I knew the hub that rotated the table worked off a gear from the handwheel shaft but I wasn't expecting this arrangement. The handwheel connects to a short axle with a small gear which drives this larger ring gear (I'm sure I don't have the terms right) which is attached to the hub shaft.

Quite an elegant arrangement.

There was a pretty good buildup of crud on the table handwheel so I took it off for cleaning. I knew the hub that rotated the table worked off a gear from the handwheel shaft but I wasn't expecting this arrangement. The handwheel connects to a short axle with a small gear which drives this larger ring gear (I'm sure I don't have the terms right) which is attached to the hub shaft.

Quite an elegant arrangement.

historicalarms

Ultra Member

sounds like a sort of single gear planetary reduction set-up...they didn't spare "quality" when they built that thing.

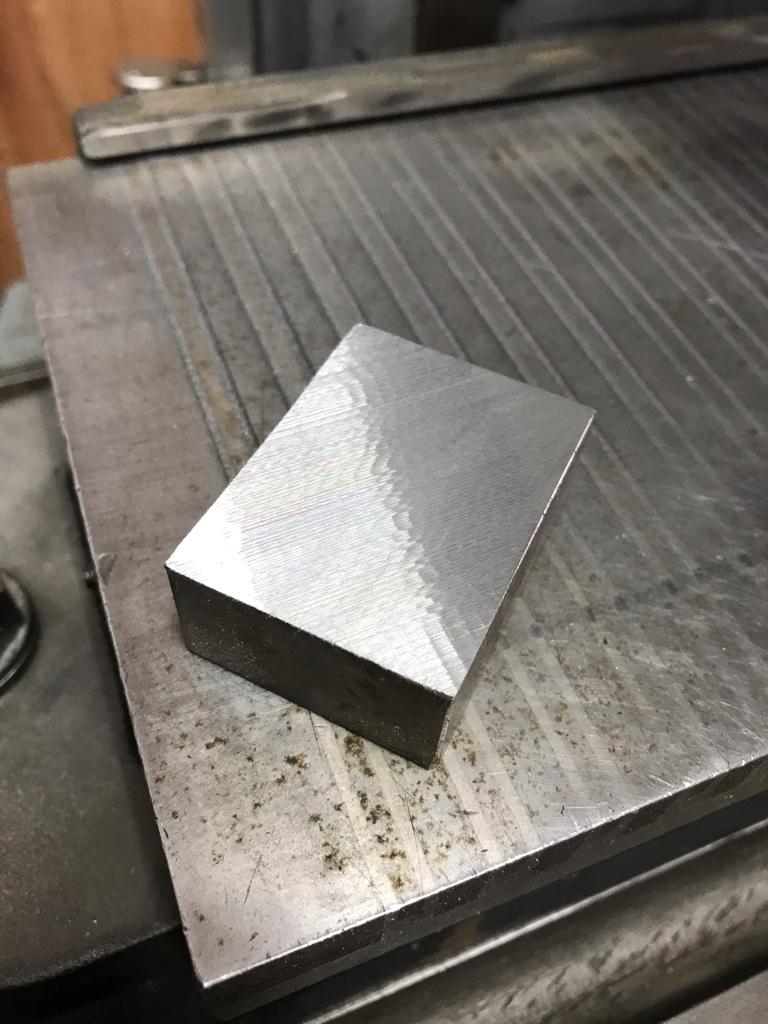

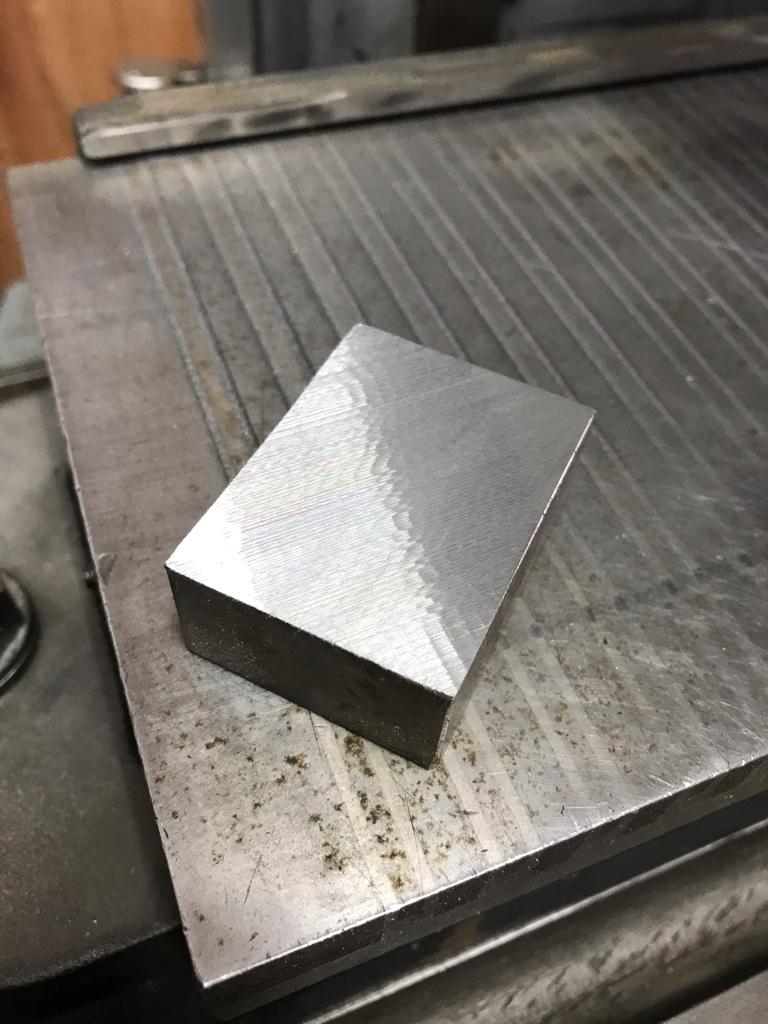

It lives!

Undressed wheel because KBC is sold out of the diamond dresser I ordered.

But the table went back on just fine.

Table is silky smooth.

Definitely takes some coordination to grind smoothly though I can see it being a bit of a zen activity.

Undressed wheel because KBC is sold out of the diamond dresser I ordered.

But the table went back on just fine.

Table is silky smooth.

Definitely takes some coordination to grind smoothly though I can see it being a bit of a zen activity.

The pump is 3-phase so I'll need to get another VFD or I could just buy a complete system. The tank is a real brute. It's made from 3/16" plate and probably weighs 100 lbs empty. Other than the tank and pump there are no other coolant parts. So all of that will also need to be sorted out.Precision objects, here we come! LOL

Are you going to use the default coolant system or you have something else in mind?

One advantage of using the existing system is that the tank fits neatly under the grinder though I'd have to pull it forward to get it back in.

So for about the same money as a VFD I could get a full system but I haven't done a lot of research yet.

I'm not a pump expert but maybe its constant flow & more/less fluid at the nozzle might just be diverting more/less to bypass with the valve?. ie. maybe you just need a matching watt/rpm 110v motor vs variable rpm capability?

Indeed.

Coolant flow is likely best controlled by a valve and not by lowering the speed of the motor.

The hesitation I have with the existing pump and tank is its weight. I have to use a hand truck to move it so trying to wrestle it out when it’s in the base against the wall would be a nightmare. It also requires the machine be a full 18” -24” away from the wall and I can’t afford to give away the floor space.

I will likely clean it out, take the pump off the tank, put it in the tank and either put it back in place or store it and put a plastic tank system in it’s place.

historicalarms

Ultra Member

I have another "cheap bastard-farmer fix" for you. My lathe didn't come with a coolant system of any kind so, after reading all the old "how too" books on machining, I decided the only way I was going to get any satisfactory turning results was to purchase an add-on spray system...but holly damn they were "spencif" from the store-bought place.

So the "what would I do if still farming" brain mater slooowly started to turn, and kicked into high gear the day I had to pick the wife up from the Greenhouse supply store she worked at. Just inside the door they had a display of garden/fish pond submersible pumpsso I picked out a mid priced one (around $40 but I cant remember the GPM rating). wish I could remember because it was twice what I needed.

She was a little late getting home from work that day as I needed to make a stop at CT for some feet of plastic tubing(1/4") and an assortment of brass hose couplers& a couple of valves.

I originally cobbled the pump & hose direct together with a nozzle at the end and plunked the pump into my reservoir with a couple gallons of cutting oil solution...a surplus five gallon plastic pail, and let er rip...this is when I discovered I had waaaay more GPM than I needed...that $hit was like red hot sauce...it went everywhere.

So back to the drawing board and installed a needle control valve in-line with a return line plumbed in just before it (between needle valve & pump). Now I could control the flow & pressure at the nozzle easily and the excess just flows back thru the return.

runs on 110V & Total cost was probably under 60 bucks, 250 less than store-bought at the time.

I did "store bought " one of those $8 flex nozzles that BB sells later on for the system but that's about the only change I've made in the more than 20 yrs I've used it.

So the "what would I do if still farming" brain mater slooowly started to turn, and kicked into high gear the day I had to pick the wife up from the Greenhouse supply store she worked at. Just inside the door they had a display of garden/fish pond submersible pumpsso I picked out a mid priced one (around $40 but I cant remember the GPM rating). wish I could remember because it was twice what I needed.

She was a little late getting home from work that day as I needed to make a stop at CT for some feet of plastic tubing(1/4") and an assortment of brass hose couplers& a couple of valves.

I originally cobbled the pump & hose direct together with a nozzle at the end and plunked the pump into my reservoir with a couple gallons of cutting oil solution...a surplus five gallon plastic pail, and let er rip...this is when I discovered I had waaaay more GPM than I needed...that $hit was like red hot sauce...it went everywhere.

So back to the drawing board and installed a needle control valve in-line with a return line plumbed in just before it (between needle valve & pump). Now I could control the flow & pressure at the nozzle easily and the excess just flows back thru the return.

runs on 110V & Total cost was probably under 60 bucks, 250 less than store-bought at the time.

I did "store bought " one of those $8 flex nozzles that BB sells later on for the system but that's about the only change I've made in the more than 20 yrs I've used it.

Now that I've stopped laughing at the mental images of coolant going everywhere at high pressure.... Thanks for the grinsI have another "cheap bastard-farmer fix" for you. My lathe didn't come with a coolant system of any kind so, after reading all the old "how too" books on machining, I decided the only way I was going to get any satisfactory turning results was to purchase an add-on spray system...but holly damn they were "spencif" from the store-bought place.

So the "what would I do if still farming" brain mater slooowly started to turn, and kicked into high gear the day I had to pick the wife up from the Greenhouse supply store she worked at. Just inside the door they had a display of garden/fish pond submersible pumpsso I picked out a mid priced one (around $40 but I cant remember the GPM rating). wish I could remember because it was twice what I needed.

She was a little late getting home from work that day as I needed to make a stop at CT for some feet of plastic tubing(1/4") and an assortment of brass hose couplers& a couple of valves.

I originally cobbled the pump & hose direct together with a nozzle at the end and plunked the pump into my reservoir with a couple gallons of cutting oil solution...a surplus five gallon plastic pail, and let er rip...this is when I discovered I had waaaay more GPM than I needed...that $hit was like red hot sauce...it went everywhere.

So back to the drawing board and installed a needle control valve in-line with a return line plumbed in just before it (between needle valve & pump). Now I could control the flow & pressure at the nozzle easily and the excess just flows back thru the return.

runs on 110V & Total cost was probably under 60 bucks, 250 less than store-bought at the time.

I did "store bought " one of those $8 flex nozzles that BB sells later on for the system but that's about the only change I've made in the more than 20 yrs I've used it.

This is exactly the kind of setup I'm thinking about, but I think I hear you saying to go conservative on the GPH rating

I agree with @historicalarms : you don’t need much. As a matter of fact, my Carolina Industrial bandsaw comes with a Little Giant pond pump for coolant from factory. Plenty of flow through a little 1/4” plastic tube. I even turn the needle valve all the way down so I just have a trickle.

My SM 1340 has the “submersible-pump-in-5 gallon-bucket” coolant system (designed by the previous owner). The tubing is 1/2”. I have only used it once - way too much flow. Coolant goes everywhere. So I just put the coolant in a spritzer bottle and use it that way (if I need coolant).

I prefer cutting oil for lubrication as I just don’t like the idea of water-based fluids on clean metal surfaces. Probably just paranoid that it would rust.

I know all modern CNC machines use coolant (water based for the most part) without any problems - maybe some day my old brain will be ok with it and i will switch.

My SM 1340 has the “submersible-pump-in-5 gallon-bucket” coolant system (designed by the previous owner). The tubing is 1/2”. I have only used it once - way too much flow. Coolant goes everywhere. So I just put the coolant in a spritzer bottle and use it that way (if I need coolant).

I prefer cutting oil for lubrication as I just don’t like the idea of water-based fluids on clean metal surfaces. Probably just paranoid that it would rust.

I know all modern CNC machines use coolant (water based for the most part) without any problems - maybe some day my old brain will be ok with it and i will switch.

I went with this pump from the home depot. It is made for a tile saw. I have this in my parts washer barrel, very subtle flow. $35

Home Depot Pump

Home Depot Pump