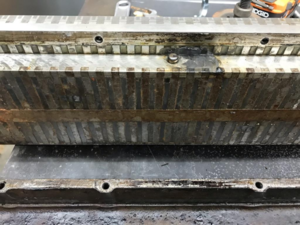

I thought I’d start a thread to document the general clean up of the Parker Majestic.

I wrestled it into place this morning.

I don’t have any in progress pics as I was too busy trying to keep it blocked amd level.

Edit: I used my 2-ton engine hoist to lift and position the machine.

All in all it went well. I used two 10’ long straps each rated for 2600lbs in cradle configuration (12 footers would have been better) and ran a chain rated for 5 tons through the loops of the straps and connected the ends with a 2 ton connector.

The hook was just above the spindle so I had clearance to the beam in my shop.

Once the hoist was bearing the weight I pushed and turned it into place.

Went well actually.

![0fa013f716fc5d9e6c367e99296c3168.jpg]()

Sent from my iPhone using Tapatalk

I wrestled it into place this morning.

I don’t have any in progress pics as I was too busy trying to keep it blocked amd level.

Edit: I used my 2-ton engine hoist to lift and position the machine.

All in all it went well. I used two 10’ long straps each rated for 2600lbs in cradle configuration (12 footers would have been better) and ran a chain rated for 5 tons through the loops of the straps and connected the ends with a 2 ton connector.

The hook was just above the spindle so I had clearance to the beam in my shop.

Once the hoist was bearing the weight I pushed and turned it into place.

Went well actually.

Sent from my iPhone using Tapatalk

Last edited: