I have arranged to have a friend with a tilt deck trailer meet me to pick it up Thursday afternoon. The beer will be free and I have plenty of chairs.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New 10" X 54" mill ordered.

- Thread starter John Conroy

- Start date

I got a call just before noon, the mill is here. The lady I talked to on the phone asked when they could deliver it. I told her I think it's too heavy for liftgate service at 3300 lbs. She said that's not too heavy, they can deliver it. I asked her to check with the guys on the loading dock. She called back 15 minutes later and said the liftgate max weight is 1500 lbs, as I suspected. We are going to pick it up tomorrow afternoon, unfortunately my friend with the trailer has to work in the morning. I'll take as many pics as I can documenting the unloading and un-crating.

Awesome, thanks for letting us join in the adventure! I for one have learned a lot from your documentation and details, it's amazing how anything reaches its final destination in reasonable time given all the many layers of transportation and logistics involved!

I'll be watching for pictures too. If my family wasn't all dealing with a horrible cold (no, not COVID, tested negative) I'd pop over.

I'll be watching for pictures too. If my family wasn't all dealing with a horrible cold (no, not COVID, tested negative) I'd pop over.

I'm not sure what kind of trailer your friend has but a drop deck trailer is the best way to move stuff like this. I rent them from sunbelt as I haven't found anywhere else that has them here, but because they squat down flat to the ground you can move top heavy things (like a mill) quite easily using a pallet jack (if it will take the weight). I don't think that I'll move a machine without one since I found them, it's a lot less scary when moving things that have the majority of their weight so high up.I got a call just before noon, the mill is here. The lady I talked to on the phone asked when they could deliver it. I told her I think it's too heavy for liftgate service at 3300 lbs. She said that's not too heavy, they can deliver it. I asked her to check with the guys on the loading dock. She called back 15 minutes later and said the liftgate max weight is 1500 lbs, as I suspected. We are going to pick it up tomorrow afternoon, unfortunately my friend with the trailer has to work in the morning. I'll take as many pics as I can documenting the unloading and un-crating.

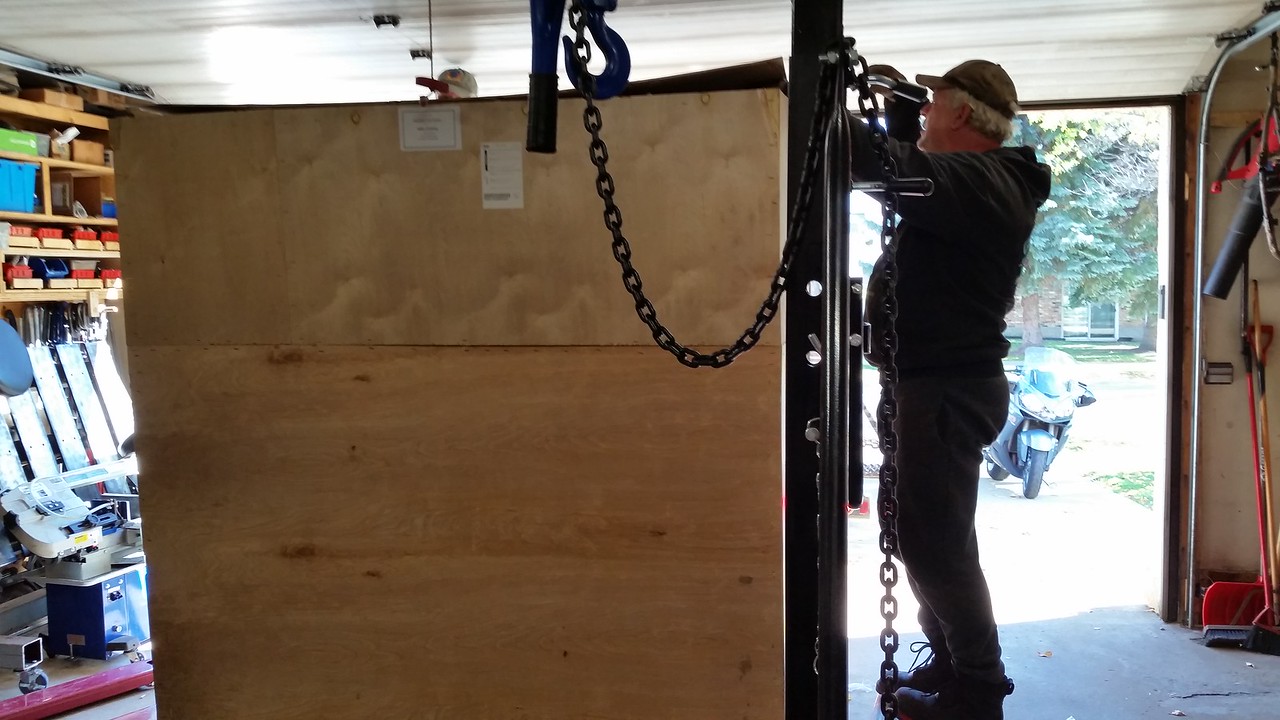

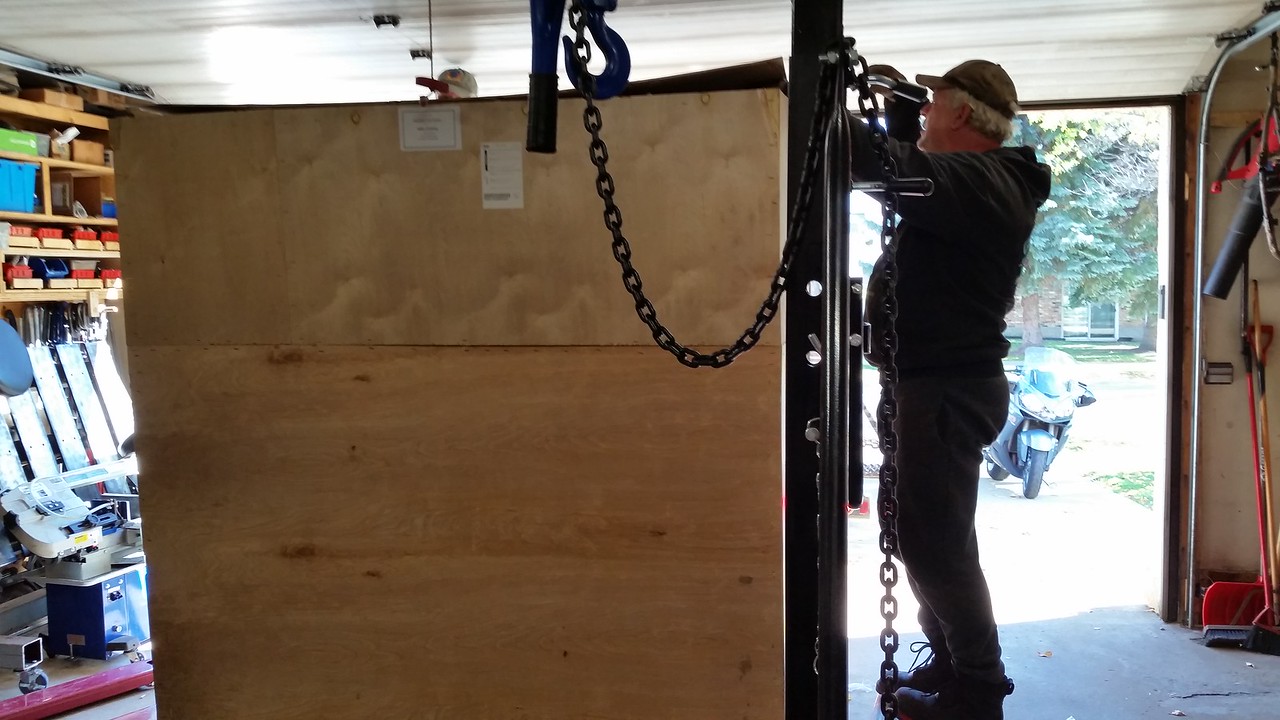

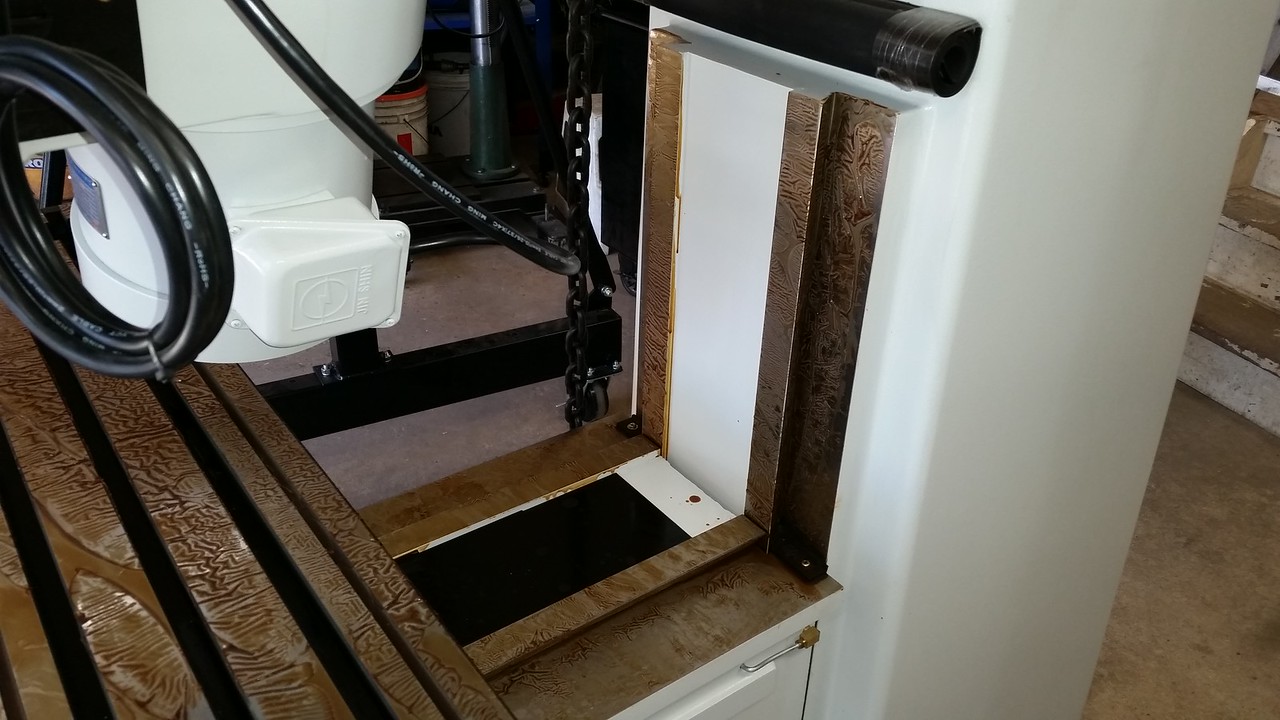

Well we got the new mill home safely. Started the day getting the gantry crane adjusted to the highest it can go in the sweet spot in the garage where there is nothing on the ceiling to hit. The beam clamp and chain hoist in place and ready to go.

I met my friend Glenn at Pacific Coast Express and they loaded it onto Glenn's' trailer deck. The crate is 66" X 66" X 76" tall and the fork lift operator made short work of it. The crate was in perfect condition which made me very happy.

Once at my place Glenn got the trailer backed in with it's tail aligned with the door opening and we double checked the clearance through the 8' tall door opening. We put a strap around the belly of the crate and connected it to the winch cable then put the pallet jack under the downhill side. We lifted the crate just high enough so it would roll down the deck slowly as the winch was rolling the cable out until the bottom edge was off the trailer. Then with the pallet jack raised as high as it would go we put the machine skates under the bottom corners.

Then we moved the pallet jack to the uphill side. The skates allowed the bottom edge to roll into the garage as soon as the weight was raised and we let it down slowly with the winch.

We jacked up the pallet jack as high as it would go and placed the other 2 skates under the front edge and when we lowered the jack the weight was all on the skates and it rolled easily into the garage.

I met my friend Glenn at Pacific Coast Express and they loaded it onto Glenn's' trailer deck. The crate is 66" X 66" X 76" tall and the fork lift operator made short work of it. The crate was in perfect condition which made me very happy.

Once at my place Glenn got the trailer backed in with it's tail aligned with the door opening and we double checked the clearance through the 8' tall door opening. We put a strap around the belly of the crate and connected it to the winch cable then put the pallet jack under the downhill side. We lifted the crate just high enough so it would roll down the deck slowly as the winch was rolling the cable out until the bottom edge was off the trailer. Then with the pallet jack raised as high as it would go we put the machine skates under the bottom corners.

Then we moved the pallet jack to the uphill side. The skates allowed the bottom edge to roll into the garage as soon as the weight was raised and we let it down slowly with the winch.

We jacked up the pallet jack as high as it would go and placed the other 2 skates under the front edge and when we lowered the jack the weight was all on the skates and it rolled easily into the garage.

Once all 4 corners were on skates and we rolled it into the garage we celebrated with a cold beer.

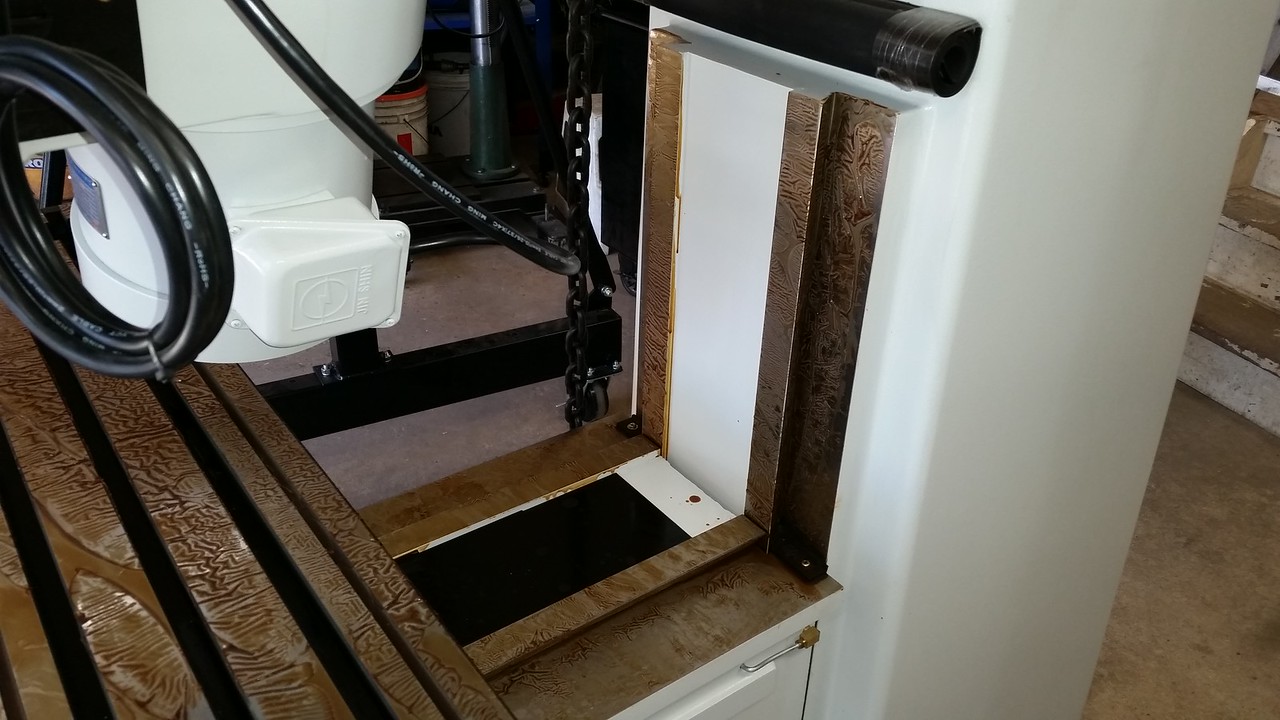

Then we popped the top and sides off the crate, which was amazingly flimsy. I think the plastic wrap around the outside was most of what was holding it together.

With the shell removed we rolled it under the center of the gantry crane and stripped off all the plastic and removed the accessories from the crate.

With all that stuff out of the way we removed the 4 half inch lag bolts holding it to the pallet and raised it with the chain hoist so we could drag the pallet from under it .

We set it down on the skates and had a close look at the machine. As far as I can tell it all looks good but I'll have to clean off all this packing grease to be sure.

The pre-delivery inspection was done on Sept 9 according to the tag they put on the head.

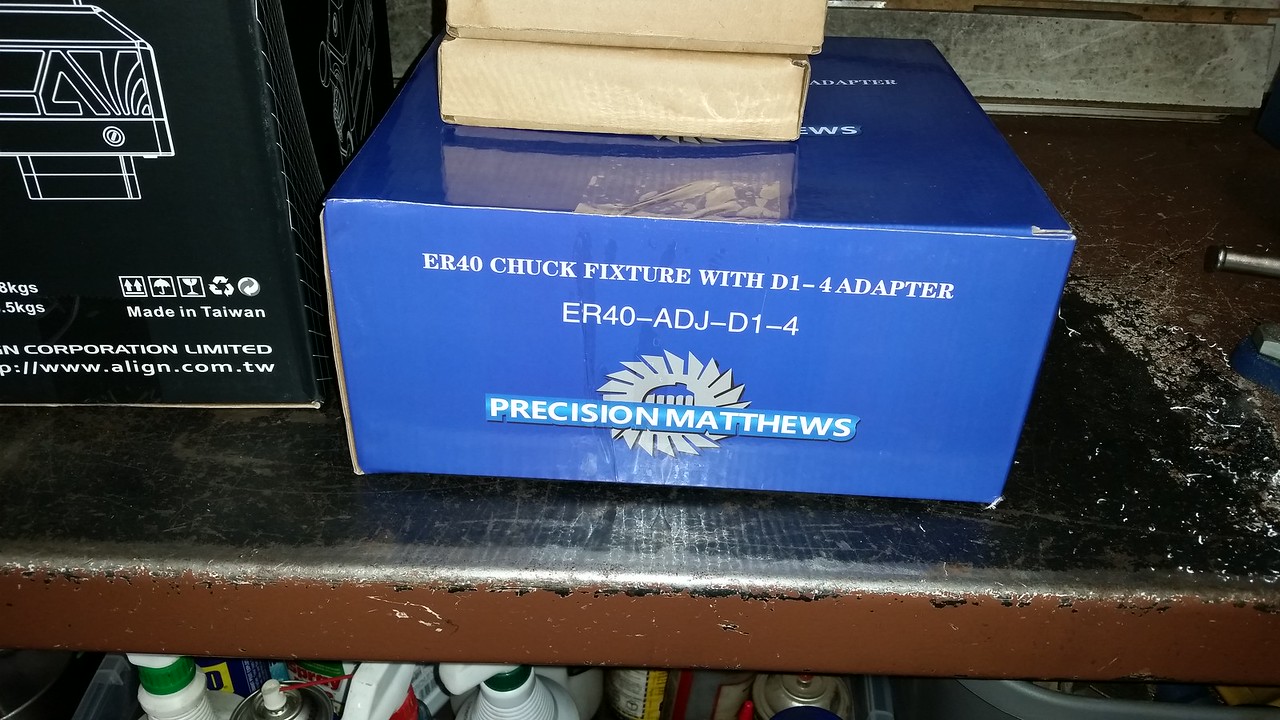

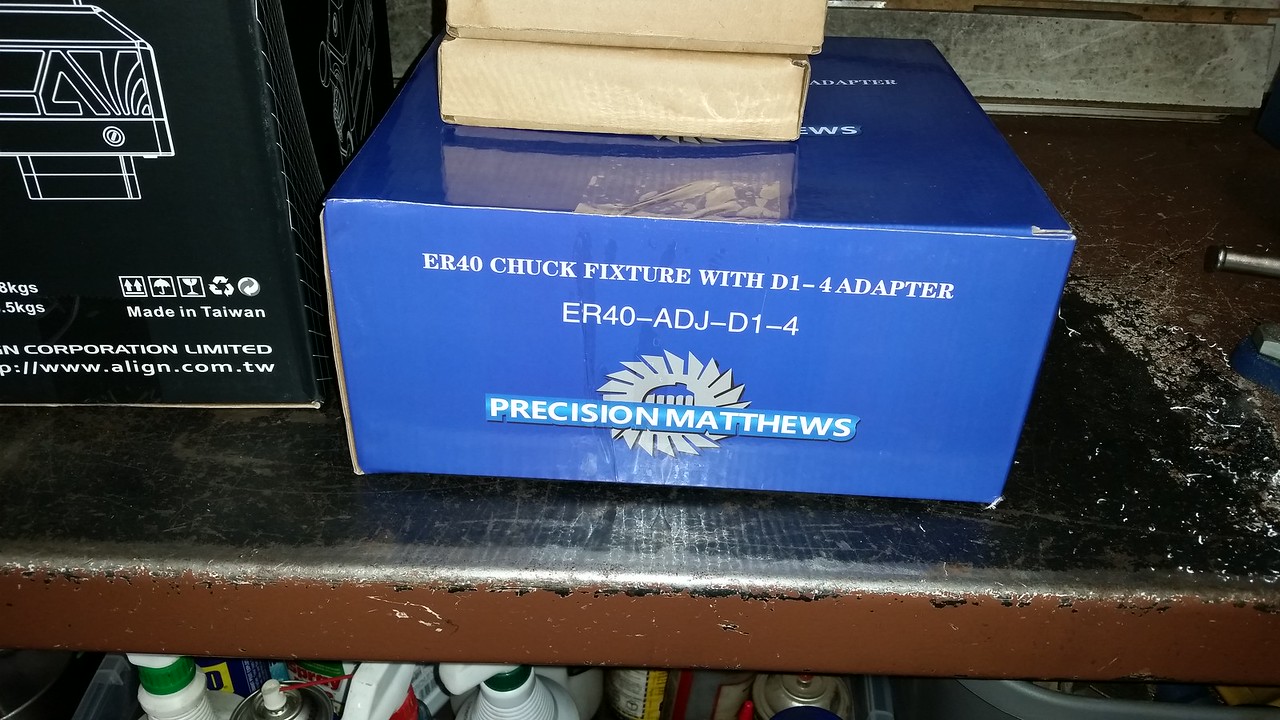

All the accessories I ordered were in the crate and now the fun begins to install 3 power feeds, a DRO, a power draw bar and the VFD.

The ER40 collet chuck I ordered for my lathe was in there as well as a R8-ER40 chuck for the mill. The ER40 wrench even fits the chuck Mike!

That's it for today, tomorrow morning the cleaning of the brown spooge will begin.

Then we popped the top and sides off the crate, which was amazingly flimsy. I think the plastic wrap around the outside was most of what was holding it together.

With the shell removed we rolled it under the center of the gantry crane and stripped off all the plastic and removed the accessories from the crate.

With all that stuff out of the way we removed the 4 half inch lag bolts holding it to the pallet and raised it with the chain hoist so we could drag the pallet from under it .

We set it down on the skates and had a close look at the machine. As far as I can tell it all looks good but I'll have to clean off all this packing grease to be sure.

The pre-delivery inspection was done on Sept 9 according to the tag they put on the head.

All the accessories I ordered were in the crate and now the fun begins to install 3 power feeds, a DRO, a power draw bar and the VFD.

The ER40 collet chuck I ordered for my lathe was in there as well as a R8-ER40 chuck for the mill. The ER40 wrench even fits the chuck Mike!

That's it for today, tomorrow morning the cleaning of the brown spooge will begin.

Last edited:

There will be lots of drilling and tapping I'm sure.

I am totally thrilled for you @John Conroy. I can't wait to see it all cleaned up and ready to make chips. Wish I could see that little boy look on your face right now.

When my lathe arrived, there were two horizontal slots in the box. Exactly what you would expect when an unhappy forklift driver tries his very best to damage the contents. Fortunately, the forks went into empty space inside and nothing was damaged. I'm glad nobody was there to take a picture of my face when I saw those holes.......

When I saw the photo of you rolling it off the flatbed, that's all I could think. Omg, what if that box collapses? In my experience, everything gets fastened to the base skid, and the box is just a dust cover.

Anyway, thanks for sharing John, I'm luvin it!

The crate was in perfect condition which made me very happy.

When my lathe arrived, there were two horizontal slots in the box. Exactly what you would expect when an unhappy forklift driver tries his very best to damage the contents. Fortunately, the forks went into empty space inside and nothing was damaged. I'm glad nobody was there to take a picture of my face when I saw those holes.......

Then we popped the top and sides off the crate, which was amazingly flimsy. I think the plastic wrap around the outside was most of what was holding it together.

When I saw the photo of you rolling it off the flatbed, that's all I could think. Omg, what if that box collapses? In my experience, everything gets fastened to the base skid, and the box is just a dust cover.

Anyway, thanks for sharing John, I'm luvin it!