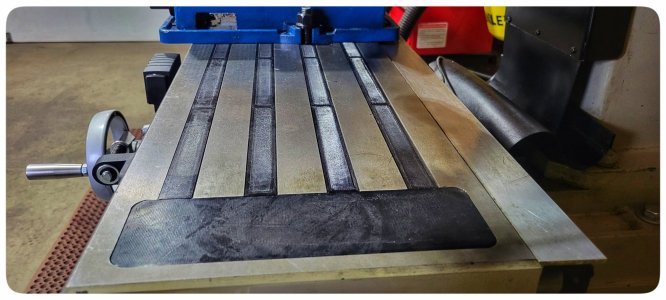

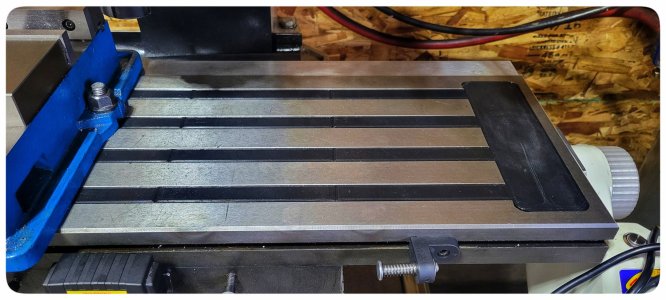

Vise will also have to move over 2-3" and I'm thinking I'll permanently leave the vise off to the side so when I put the rotary table on in the future I don't have to mess with the vise. Won't hurt to put a little wear in the ways on the side either

I leave my vise in the center and only put my rotary table on the left side when I use it. I prefer not to ever move my.vise.

But your comment about lead screw wear makes me wonder if what I do it a good idea or not. I wonder what others do. I wonder if there is a commended practice. If no one posts here, I might start a new thread on it. It's a very good question and I'm glad you mentioned it.