Jswain

Joe

Figured I would make my own thread as I'm always tinkering in the shop. Be forewarned I am a very amateur machinist

First project is adding one of the cheap vevor power feeds to my RF45 mill. Of course I did not splurge for the more expensive bolt on unit, why make it easy?

I started by swapping the x axis lead screw end for end, as well as the thrust bearing was moved to the left so I can install the power feed(hopefully) on the right, clocked clockwise enough to clear the table.

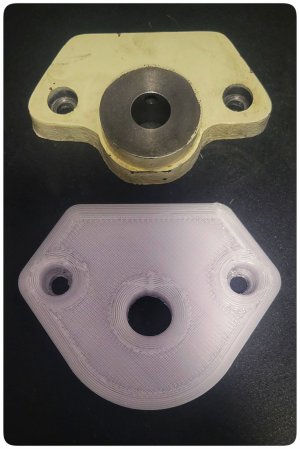

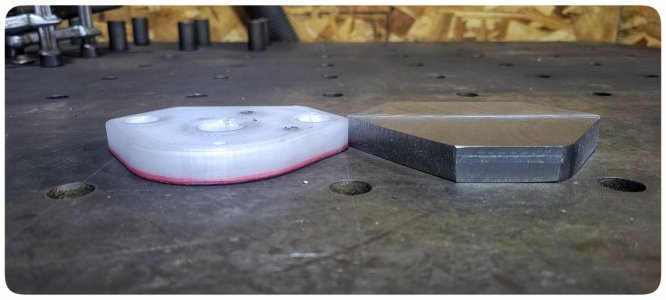

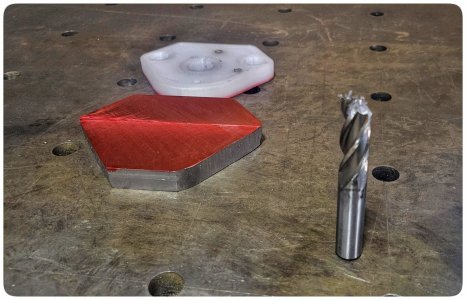

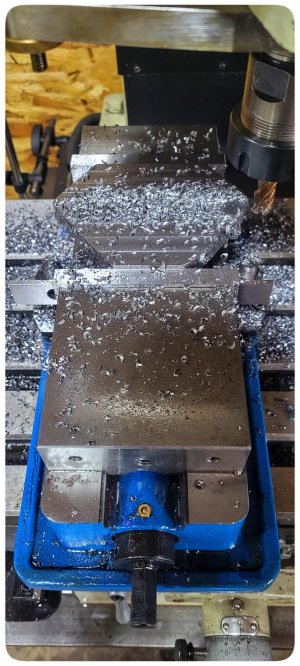

I used the cast iron lead screw support I removed to measure & make an adapter in fusion360 which is on the printer now. Once I figure out how much to clock the power feed I will drill & tap it for the mounting screws.

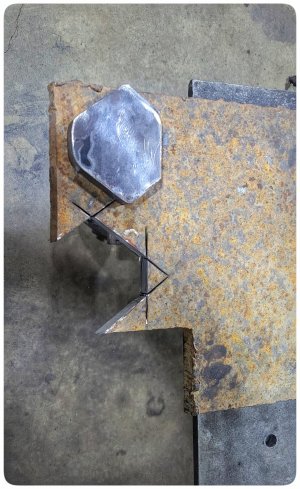

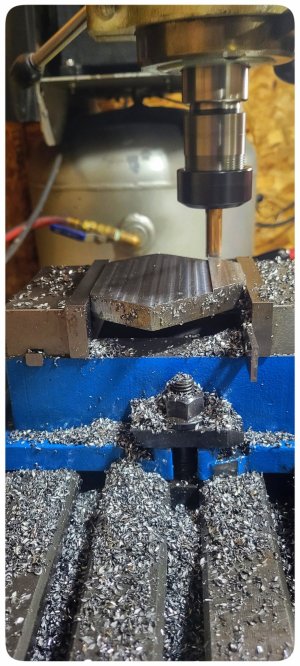

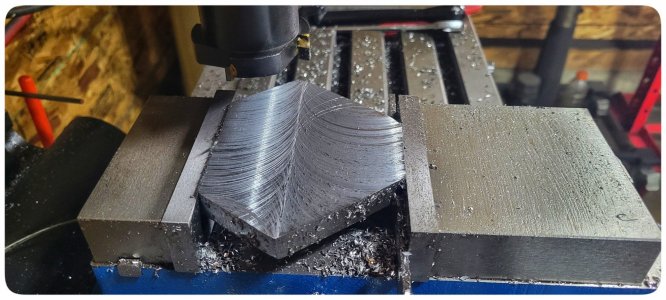

Plan is to 3d print whatever I will need to make it happen, then I will make the parts out of steel or aluminum. Looks like I will need to make a bushing for the bearing, bore & part the brass gear, and drill it for some set screws. Similar to how @YYCHM & @David_R8 attached theirs except on the other side.

First project is adding one of the cheap vevor power feeds to my RF45 mill. Of course I did not splurge for the more expensive bolt on unit, why make it easy?

I started by swapping the x axis lead screw end for end, as well as the thrust bearing was moved to the left so I can install the power feed(hopefully) on the right, clocked clockwise enough to clear the table.

I used the cast iron lead screw support I removed to measure & make an adapter in fusion360 which is on the printer now. Once I figure out how much to clock the power feed I will drill & tap it for the mounting screws.

Plan is to 3d print whatever I will need to make it happen, then I will make the parts out of steel or aluminum. Looks like I will need to make a bushing for the bearing, bore & part the brass gear, and drill it for some set screws. Similar to how @YYCHM & @David_R8 attached theirs except on the other side.