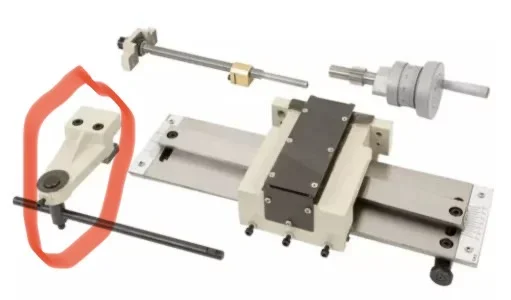

My lathe a Harrison M300 came with a taper attachment. I have only used it twice so far. So to answer your question is it worth it. I looked up the price to buy a new one for my lathe. The replacement cost is $4,947.83 USD. That's the price before shipping, exchange, taxes etc. I suppose to me if I had to make the choice a used one at less than $1k might be worth it. If I had to buy a new one the price would pay for a lot of trips to my friends machine shop where I could use his bigger lathe.

The cost of the oem attachment for my lathe is around a grand with exchange and shipping, and the trip to the nearest machine is prolly a hundred with 2hrs of diesel oil and a case of beer. Prolly someone closer, but I don't know them...... yet.....