RobinHood

Ultra Member

Thanks for the reference. This is good stuff."The cutting force when turning is a resultant force that combines tangential, feed and radial force components. These force components can be measured with a three-component force dynamometer. Metalcutting professionals consider Kistler dynamometers the most accurate.

Of the three cutting force components, the tangential force (FZ) is the greatest, the feed force (FY) is less in magnitude and the radial force (FX) is the least in magnitude. As a rule of thumb, the following relationships are used, but it is not a good practice because the results are not as accurate as they could be: FY = 0.50FZ and FX = 0.25FZ."

Calculated forces when turning | Cutting Tool Engineering

The cutting force when turning is a resultant force that combines tangential, feed and radial force components. These force components can be measured with a three-component force dynamometer. Metalcutting professionals consider Kistler dynamometers the most accurate.www.ctemag.com

View attachment 38942

An observation: Fr (or FY in the description) heavily depends on the nose geometry of the insert / cutting tool. I had it go negative (ie, the tool was “sucked“ into the part) and thus screwed up the dimension. (The lathe had a fair bit of backlash in the cross slide - hence the tool was able to pull in by the lash amount). This only happened at certain DoC, feed rate and insert used.

A great way to observe the Fr (FY) force (and rigidity issues) is after the cut is complete and the carriage is wound back to the start without retracting the tool. If the tool leaves a “witness spiral” you have had a lot of Fr (FY) tool pressure. If there is no spiral, then the tool was able to withstand the Fr (FY) force with its rigidity. If there is no spiral but you can see light between the tool and the work piece, Fr (FY) was negative and the tool was “sucked“ into the part.

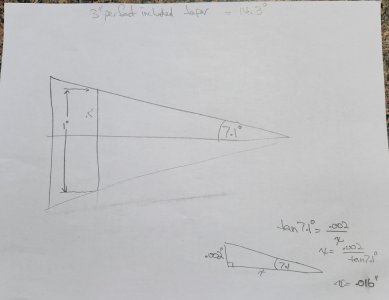

Getting back to a TTA: since it introduces more moving components (each with a certain amount of clearance to make it work), one needs to be aware of backlash (and reduced rigidity) when using one. I found that was the biggest contributor to inaccurate angles. The sine bar set-up can be perfect, but it may still not give you the correct angle. So expect some trial and error.