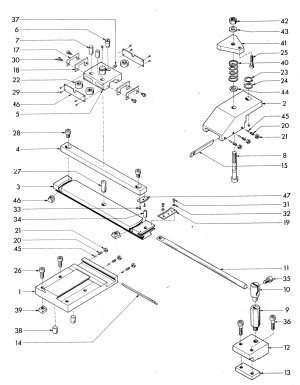

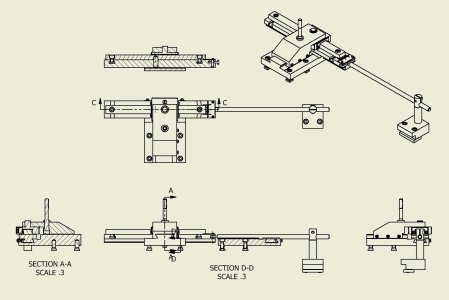

To achieve that, it looks like that slide is tethered to the lathe base with a rod so it is fixed in position on the Z axis independent of carriage motion. You can see the rod in one of @Darren ’s photos of parts in post #88.

Yes. I guess I assumed that all taper attachments did that. The OEM TA for my lathe does it like that too. So for me, that part was the easy part (the light bulb glow). I just couldn't see how that got translated into a solid tool movement to cut the taper.

I also wonder how much of cosine angle effect the tether bar has when doing large angle tapers.

Assuming that it's like the one for my lathe, it doesn't matter because neither the bar or the taper guide move once they are set and locked in place. Whatever sine error is there simply becomes part of the taper itself!

Whew! That’s complicated! The trade off here is the multiple slides (precision?)

If I have any remaining concerns, you have nailed it. There is lot going on there and my mind simply cannot grapple with their combined effects. By the time I have one nailed, I've forgotten how the one before it worked! I think they are simply additive. My biggest concern is flex in the taper guide dovetail-bar and the tether rod under load. I suspect small cuts are required to keep the cutting pressure load low - no big deal really.

Overall, I am VERY IMPRESSED!