TTA arrived. It's a beast! Guessing altogether it weighs 85 pounds!

No problems with UPS....... this time......

The kit replaces the leade screw and cross-slide handle wheel for my cross-slide so that the leade screw anchor is at the rear in the taper attachment at the rear of the saddle instead of at the front of the saddle. So when you dial in some cross-slide movement, it's all relative to the rear taper position instead of the saddle.

Trouble is that the taper attachment was made in China, and it looks it. My lathe was made in Taiwan so I just assumed that the TA would be made in Taiwan too. You know what they say about assume.......

The Castings have voids and there are dings in the ways. There are some machining marks on the taper ways too.

Most of the scales are loose, or bent, or damaged.

The taper adjustment screw system is sticky and jams. The thumb wheel should be 4x the size. Not sure what I'll do with this just yet. I like smooth adjustments so it can't stay like it is.

Some of the damage might be shipping. Lotta big parts loose in the same wooden box.

After I do an inventory, I'll reach out to Grizzly to see what they want to do.

@kevin.decelles - see the photos of the way clamp. It's not good as is either, but I can easily see how to make it much better. BTW, this is not a used part. It's brand spanking new.....

The casting pore on the surface could be machined away but it shouldn't affect function as is. The deliberate broken edge is also an eyesore and the ledge is a mm too wide. I think I'll machine the whole end off and replace it with a piece of screwed on plate to take up the clearance and look better too.

The pin that holds the stay bar is actually too loose and would generate a few thou of backlash in the taper system. I'll prolly make a new pin with a better fit. It's that or redesign the whole way stop

Also in the photo is the bottom clamp that fits under the rear way.

When all assembled and tightened, it doesn't get tight enough to hold anything.

Here is the rest of the TA minus the stay rod.

The large block attaches to the back of the saddle and anchors the end of the new leade screw inside it.

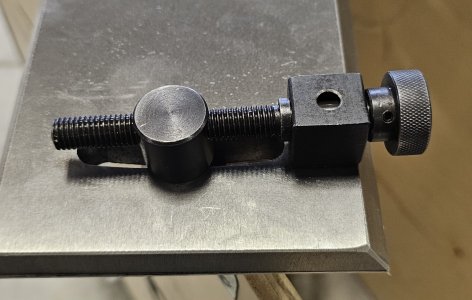

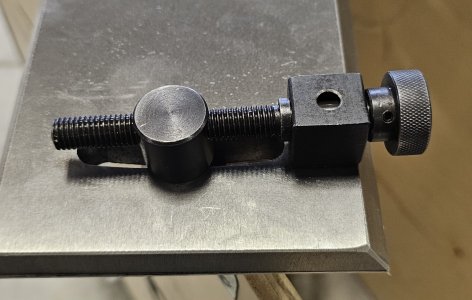

Here is a photo of the taper adjustment knob, screw, and block. Not satisfying at all. Binds, sticks, and jumps. At a minimum it needs a knob 4x as big. But a better block system would be desirable too.

In practice, it is adjusted and then locked down in 3 places with machine screws.

I'd love to be playing with the TA some more, but it's raining and my fur stinks when it gets wet so maybe tomorrow.

Questions and suggestions are welcome.

No problems with UPS....... this time......

The kit replaces the leade screw and cross-slide handle wheel for my cross-slide so that the leade screw anchor is at the rear in the taper attachment at the rear of the saddle instead of at the front of the saddle. So when you dial in some cross-slide movement, it's all relative to the rear taper position instead of the saddle.

Trouble is that the taper attachment was made in China, and it looks it. My lathe was made in Taiwan so I just assumed that the TA would be made in Taiwan too. You know what they say about assume.......

The Castings have voids and there are dings in the ways. There are some machining marks on the taper ways too.

Most of the scales are loose, or bent, or damaged.

The taper adjustment screw system is sticky and jams. The thumb wheel should be 4x the size. Not sure what I'll do with this just yet. I like smooth adjustments so it can't stay like it is.

Some of the damage might be shipping. Lotta big parts loose in the same wooden box.

After I do an inventory, I'll reach out to Grizzly to see what they want to do.

@kevin.decelles - see the photos of the way clamp. It's not good as is either, but I can easily see how to make it much better. BTW, this is not a used part. It's brand spanking new.....

The casting pore on the surface could be machined away but it shouldn't affect function as is. The deliberate broken edge is also an eyesore and the ledge is a mm too wide. I think I'll machine the whole end off and replace it with a piece of screwed on plate to take up the clearance and look better too.

The pin that holds the stay bar is actually too loose and would generate a few thou of backlash in the taper system. I'll prolly make a new pin with a better fit. It's that or redesign the whole way stop

Also in the photo is the bottom clamp that fits under the rear way.

When all assembled and tightened, it doesn't get tight enough to hold anything.

Here is the rest of the TA minus the stay rod.

The large block attaches to the back of the saddle and anchors the end of the new leade screw inside it.

Here is a photo of the taper adjustment knob, screw, and block. Not satisfying at all. Binds, sticks, and jumps. At a minimum it needs a knob 4x as big. But a better block system would be desirable too.

In practice, it is adjusted and then locked down in 3 places with machine screws.

I'd love to be playing with the TA some more, but it's raining and my fur stinks when it gets wet so maybe tomorrow.

Questions and suggestions are welcome.