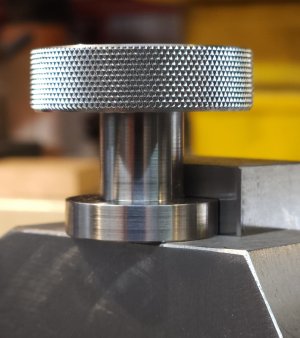

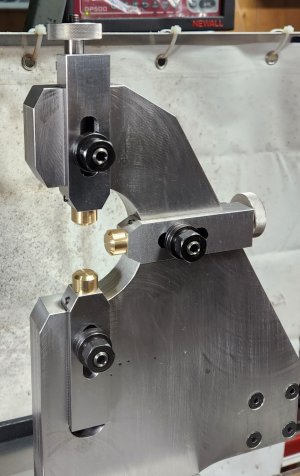

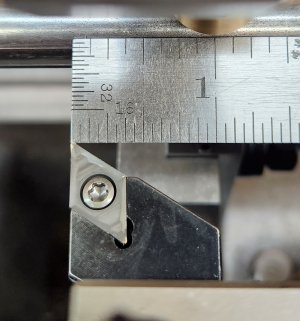

Hi Peter. Yes I did that as well.Very nice knurls. Accu-Trak is good stuff. Spendy at current FX but what isn't these days. What I like about that design is good mechanical advantage for applying required pressure & the tension rod comes back to operator. I posted this elsewhere but here is an online calculator for initial stock sizing using knurl DP inputs & all that stuff. I made a spreadsheet from Accu-Track formulas but the web calculator is easier & from what I can tell similar results. What I did in the past was make an table of incrementing 'optimal' diameters in a range you work in, say .5" thumbscrews to 1.5" whatever, then you have a handy shop reference to turn the stock diameter to for whatever knurl wheels you have.

Another thing I'm considering is a constant air blow nozzle directed at the wheels/stock made from a simple bleeder line off the compressor. Re-munching the chips on certain materials is yet another reason for mucky knurls. Operating the lathe controls & knurl & directing air seems to require one more hand than I have. I bought some of this line with those quick insert connectors for another project but it might be a good way.

Knurling: Calculator & Formulas (Diameters, Speed & Feed)

All you need about Knurling: Online Calculator, Cutting Conditions, Formulas for diameter growth and pitch.,Charts and methods.www.machiningdoctor.com

The Machining doctor site is super informative. I've used the threading section often for custom threads.

I was thinking about compressor air too for knurling, but I use tons of cutting oil from a spray bottle for this application, so using air would just blow all the oil away. I don't know which would be better...oil or air?

Last edited: