Yeah, I just Googled: ESAB 100a, good for 1", $6,000.00! Not gonna happen!A plasma torch capable of 1" cuts would be a major investment for the home shop guy. 😵

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Follow Rest for Standard Modern

- Thread starter thestelster

- Start date

Yeah, I just Googled: ESAB 100a, good for 1", $6,000.00! Not gonna happen!

I cut thick plate fairly often repairing or modifying farm equipment. When I suggested plasma I wasn't suggesting that you buy a plasma machine. I have a fab shop a half hour away in Blenheim that has a big huge CNC plasma table. Pretty sure it will cut 3 inch plate. They cut 1/2 plate and 1 inch plate for me fairly often at a modest charge and will even do it by hand if asked.

They also have a big rack of cutoffs I can buy from at very reasonable cost. Unfortunately, it's usually mystery metal.

For what you were doing I would have marked it and rough cut it by hand with an OA cutting torch (very easy to cut curves that way) and then maybe cleaned it up on the mill. I confess to cleaning stuff up freehand without a vise for big parts like that. (I'm not recommending that to anyone, I'm just confessing that I have.) I've also used a side grinder to round edges too, but those things are sooooo dangerous - I avoid them whenever possible.

Last edited:

DPittman

Ultra Member

Well having "dead steady hands" is helpful but the rest of the body being dead...well not so much.Ya, but I am no torch wizard. I'll be dead before I ever get that good!

historicalarms

Ultra Member

I have both band saw and torch capability to cut that piece but think I would go the same route the OP did with the saw.

Against using the Torch (correction, from saw to torch): first as others have stated about themselves, I am not an expert with the torch , I never was before and now shakiness & eye site issues have made it much more challenging.

The second issue that would concern me using the torch is uneven heat warpage of the plate when done, that 1" plate will take a lot of heat to remove the extra chunk, especially with a less than expert torch man. I just wouldnt want the op's care in measuring & marking/making his product to be bent out of shape by hurrying the last bit of work.

Against using the Torch (correction, from saw to torch): first as others have stated about themselves, I am not an expert with the torch , I never was before and now shakiness & eye site issues have made it much more challenging.

The second issue that would concern me using the torch is uneven heat warpage of the plate when done, that 1" plate will take a lot of heat to remove the extra chunk, especially with a less than expert torch man. I just wouldnt want the op's care in measuring & marking/making his product to be bent out of shape by hurrying the last bit of work.

Last edited:

Hey you know what it means if your cuts all looked like a beaver chewed them out, more quality time with the grinder! 😉 no one's perfect, everyone gets one of those once and a while

That made me laugh out loud!

Here is one of my recent torch jobs. It's a half inch plate cut with an OA cutting torch and cleaned up with a bench grinder.

That beaver sure ain't pretty, but she is mine! And I actually like the hammered look it has. At least that's my story and I'm sticking to it! Ya, that's it. I like the way it looks!

I am a self confessed OA red-neck. But I don't find that a cutting torch really puts that much heat into the plate. Prolly a lot more than I think it does, but I think that the oxygen jet actually cools the edge while it burns the iron out. The worst of it is at the start to get the cut going. I like a lot of oxygen to keep the cut going despite my shaking and poor eyesight.

Now, I fully confess that that is a total guess. I suppose I should know the facts of this, but I just don't. So that's that.

What I can say is that the plate above is a plate I made to adapt my new motor to my mill head. It was as flat afterward as it was before. I know that for absolute certain because I had to mount it in my lathe to cut the motor countersink and there was essentially zero wobble because I didn't have to true it up or face it off at all.

That's my story but your mileage may vary.......

@Susquatch don't be to hard on yourself, that looks ok

Torch skills are kind of a dying thing unfortunately. Students are made to do a "cut test" to get a journeyman ticket....not sure if the instructor's are wearing beer Google's when they grade them or if guys just immediately forget how to use a torch once they complete the test, I haven't decided Wich is the case. But really part of the problem is the torch doesn't get used by hand as much as it once did, zip cuts, CNC plasma/flame tables, radiographs, bevellers, they have all taken a lot of that manual work away....I'm not complaining...hard to beat parts cut on a CNC machine!

But your right about the torch not really putting that much heat into the plate, at least not as much as a guy would think, it's not the flame actually doing the cutting, and your not actually burning anything away...technically you are rusting the plate away, the jet of oxygen is rapidly oxidizing the kerf area and blowing the material out, the flame is only needed to get the steel hot enough to where that rapid oxidization process is possible. You actually don't need the flame at all, if you can heat a piece of steel to that nice cherry red (induction heater, electric arc, furnace, etc) you only need that jet of oxygen to cut it. It's also the reason you can only cut steel with any oxy torch, no iron, nothing to oxidize, no cutting action.

Anyways, that was long winded! Being good with a torch is the same as being good at welding, practice, the more a guy torch cuts the better he is (or you hope)

Torch skills are kind of a dying thing unfortunately. Students are made to do a "cut test" to get a journeyman ticket....not sure if the instructor's are wearing beer Google's when they grade them or if guys just immediately forget how to use a torch once they complete the test, I haven't decided Wich is the case. But really part of the problem is the torch doesn't get used by hand as much as it once did, zip cuts, CNC plasma/flame tables, radiographs, bevellers, they have all taken a lot of that manual work away....I'm not complaining...hard to beat parts cut on a CNC machine!

But your right about the torch not really putting that much heat into the plate, at least not as much as a guy would think, it's not the flame actually doing the cutting, and your not actually burning anything away...technically you are rusting the plate away, the jet of oxygen is rapidly oxidizing the kerf area and blowing the material out, the flame is only needed to get the steel hot enough to where that rapid oxidization process is possible. You actually don't need the flame at all, if you can heat a piece of steel to that nice cherry red (induction heater, electric arc, furnace, etc) you only need that jet of oxygen to cut it. It's also the reason you can only cut steel with any oxy torch, no iron, nothing to oxidize, no cutting action.

Anyways, that was long winded! Being good with a torch is the same as being good at welding, practice, the more a guy torch cuts the better he is (or you hope)

A little more work today. Still a long way to go.

I would have been further along if I didn't check into the hospital with chest pains and have two stents put into a couple of blocked arteries. Not too bad considering 36hrs ago I had a surgeon's Roto-Rooter tickeling my heart!

I would have been further along if I didn't check into the hospital with chest pains and have two stents put into a couple of blocked arteries. Not too bad considering 36hrs ago I had a surgeon's Roto-Rooter tickeling my heart!

Attachments

DPittman

Ultra Member

Oh good lord man, take things easy! It's really easy to overdo things the first few days after stents.I would have been further along if I didn't check into the hospital with chest pains and have two stents put into a couple of blocked arteries. Not too bad considering 36hrs ago I had a surgeon's Ro

Is this your first chest pain/stenting episode?

Congratulations on getting care for chest pains...too many men put it off too long and then they either end up dead or have significant heart damage.

General advise to everyone....Don't wait until you're damn sure that you are having a heart attack before seeking medical help! Go when you still think it is just something you ate, pulled muscle, etc. Let the doctors confirm that you were hopefully right that "it's nothing to be worried about".

Yes, first time ever experiencing this. Started happening about 5 days ago while walking the dog...pain in the chest. Got in the house, pain gone. Happened that night while spinning on my bike. Stopped spinning, pain went away. Went to see the doctor and we scheduled cardiac testing earlest date was in 2 weeks.Oh good lord man, take things easy! It's really easy to overdo things the first few days after stents.

Is this your first chest pain/stenting episode?

Congratulations on getting care for chest pains...too many men put it off too long and then they either end up dead or have significant heart damage.

General advise to everyone....Don't wait until you're damn sure that you are having a heart attack before seeking medical help! Go when you still think it is just something you ate, pulled muscle, etc. Let the doctors confirm that you were hopefully right that "it's nothing to be worried about".

Spinning again that night, chest pain again but now radiating down my arms. I'm getting scared now. Next day walking the dog, chest pain and down both arms. Got in the house pain went away chewed a couple aspirins. Next morning, Friday, I said lets go to the hospital. The rest is history.

The attending emergency physician wanted to send me home because the xrays, and ECG, were normal, and the Troponin levels weren't high enough in his opinion. I argued and he admitted me in for further testing.

The rest is history. I feel great but now I have to take a bucket of pills everyday.

Attachments

Haha!! Give me a day or two and I'll be good. I'm actually on the bike right now spinning at a low cadence, and feel great!OMG!!! Glad to hear you are doing alright - I will not be calling you for any heavy lifting!! LOL - you take care of yourself! Anything you need that I can help you out let me know!!

Haha!! Give me a day or two and I'll be good. I'm actually on the bike right now spinning at a low cadence, and feel great!

Holy Crap Stelster! My brother just went through the same thing. So far, I'm ok on that front but that is REALLY SCARY!!! Look after yourself first! The steady rest can wait.

But ya, I understand not being able to hold still...... It's a disease almost as bad as a clogged artery.

DPittman

Ultra Member

Well good for you for following thru with listening to your own body and pushing for help, you are no doubt alive today because of it.Yes, first time ever experiencing this. Started happening about 5 days ago while walking the dog...pain in the chest. Got in the house, pain gone. Happened that night while spinning on my bike. Stopped spinning, pain went away. Went to see the doctor and we scheduled cardiac testing earlest date was in 2 weeks.

Spinning again that night, chest pain again but now radiating down my arms. I'm getting scared now. Next day walking the dog, chest pain and down both arms. Got in the house pain went away chewed a couple aspirins. Next morning, Friday, I said lets go to the hospital. The rest is history.

The attending emergency physician wanted to send me home because the xrays, and ECG, were normal, and the Troponin levels weren't high enough in his opinion. I argued and he admitted me in for further testing.

The rest is history. I feel great but now I have to take a bucket of pills everyday.

I have family history of heart disease. I was having some unknown stomach/heart burn issues and because of my family history my doc ordered a stress test despite me being only 42 at the time. Passed the stress test no problem so it was decided that it was likely stomach problems so more tests for that planned. Was out hunting deer 6 months later and was over exerting myself and dang I had severe stomach/heartburn. Sat down and rested that night and things returned back to normal. A couple of days later I was taking out garbage with and heartburn hit again. I doubted this was stomach related and called doctor and he said "get to emergency".

A few days later I had a couple of stents opening up the main back artery which was 90% blocked. Doctor says they call that the "widow maker" cuz when it gets that bad it's usually too late before it's known. Luckily, I had no heart damage cuz I got immediate care.

Five years later I had a heart attack and another 4 stents were needed and while I suffered some heart damage this time around, it was relatively small because I again had immediate care and medical action.

Looks like you and me could swap medications and never know any difference.

Now I need to get back to my cigar and steak.

Last edited:

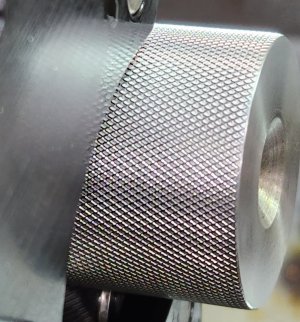

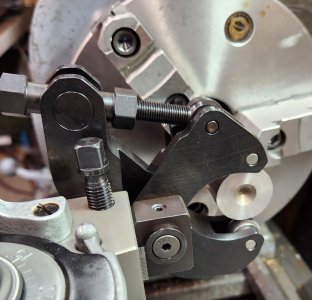

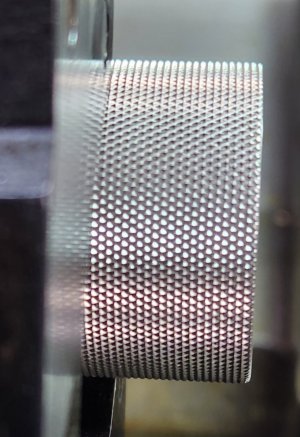

Now to make the knobs to move the fingers in and out. Looking around the shop, I found some cutoff stainless 400 series that will work. I turned the piece down to 1.250" diameter, and decided to knurl it first before any other machining, in case the knurls don't cone out right. I'm using a Accu-Trak HD Staddle knurling tool with 96DP convex knurls.

1.250" ÷ 96 = 120 Whole number, therefore it should track properly.

Speed: 160 rpm

Feed: .015 inch/rev

-Put the knurls about 0.020" before on-center in the x-axis.

-put half the knurl on the part front edge.

-cranked the tension nut abot 1/2 turn

-engaged the feed lever

-lots of cutting oil

- started the lathe.

When it got to the far end, I DID NOT DISENGAGE THE FEED, but turned the lathe off.

Examined the knurling, and it neeted to go deeper.

-tightened the tension knob about 1/4 turn

-put the feed direction lever into L.H.

-turned on the lathe.

When it got to the begining, I DID NOT DISENGAGE THE FEED, but turned the lathe off.

Examine the knurling again, and needed to go a little deeper.

-another 1/4 turn of the tension nut, put the feed direction lever in R.H., and turned the lathe on.

Knurling is good. Loosened off the tension, spread the arms, and retracted the knurler.

1.250" ÷ 96 = 120 Whole number, therefore it should track properly.

Speed: 160 rpm

Feed: .015 inch/rev

-Put the knurls about 0.020" before on-center in the x-axis.

-put half the knurl on the part front edge.

-cranked the tension nut abot 1/2 turn

-engaged the feed lever

-lots of cutting oil

- started the lathe.

When it got to the far end, I DID NOT DISENGAGE THE FEED, but turned the lathe off.

Examined the knurling, and it neeted to go deeper.

-tightened the tension knob about 1/4 turn

-put the feed direction lever into L.H.

-turned on the lathe.

When it got to the begining, I DID NOT DISENGAGE THE FEED, but turned the lathe off.

Examine the knurling again, and needed to go a little deeper.

-another 1/4 turn of the tension nut, put the feed direction lever in R.H., and turned the lathe on.

Knurling is good. Loosened off the tension, spread the arms, and retracted the knurler.

Attachments

Very nice knurls. Accu-Trak is good stuff. Spendy at current FX but what isn't these days. What I like about that design is good mechanical advantage for applying required pressure & the tension rod comes back to operator. I posted this elsewhere but here is an online calculator for initial stock sizing using knurl DP inputs & all that stuff. I made a spreadsheet from Accu-Track formulas but the web calculator is easier & from what I can tell similar results. What I did in the past was make an table of incrementing 'optimal' diameters in a range you work in, say .5" thumbscrews to 1.5" whatever, then you have a handy shop reference to turn the stock diameter to for whatever knurl wheels you have.

Another thing I'm considering is a constant air blow nozzle directed at the wheels/stock made from a simple bleeder line off the compressor. Re-munching the chips on certain materials is yet another reason for mucky knurls. Operating the lathe controls & knurl & directing air seems to require one more hand than I have. I bought some of this line with those quick insert connectors for another project but it might be a good way.

www.machiningdoctor.com

www.machiningdoctor.com

Another thing I'm considering is a constant air blow nozzle directed at the wheels/stock made from a simple bleeder line off the compressor. Re-munching the chips on certain materials is yet another reason for mucky knurls. Operating the lathe controls & knurl & directing air seems to require one more hand than I have. I bought some of this line with those quick insert connectors for another project but it might be a good way.

Knurling: Calculator & Formulas (Diameters, Speed & Feed)

All you need about Knurling: Online Calculator, Cutting Conditions, Formulas for diameter growth and pitch.,Charts and methods.

www.machiningdoctor.com

www.machiningdoctor.com

DPittman

Ultra Member

Very nice. Have you been pleased with that knurling tool?Now to make the knobs to move the fingers in and out. Looking around the shop, I found some cutoff stainless 400 series that will work. I turned the piece down to 1.250" diameter, and decided to knurl it first before any other machining, in case the knurls don't cone out right. I'm using a Accu-Trak HD Staddle knurling tool with 96DP convex knurls.

1.250" ÷ 96 = 120 Whole number, therefore it should track properly.

Speed: 160 rpm

Feed: .015 inch/rev

-Put the knurls about 0.020" before on-center in the x-axis.

-put half the knurl on the part front edge.

-cranked the tension nut abot 1/2 turn

-engaged the feed lever

-lots of cutting oil

- started the lathe.

When it got to the far end, I DID NOT DISENGAGE THE FEED, but turned the lathe off.

Examined the knurling, and it neeted to go deeper.

-tightened the tension knob about 1/4 turn

-put the feed direction lever into L.H.

-turned on the lathe.

When it got to the begining, I DID NOT DISENGAGE THE FEED, but turned the lathe off.

Examine the knurling again, and needed to go a little deeper.

-another 1/4 turn of the tension nut, put the feed direction lever in R.H., and turned the lathe on.

Knurling is good. Loosened off the tension, spread the arms, and retracted the knurler.

I debate if I should buy a better one, make one like Craig did, or maybe I need to learn more about using the one I have.

If I were to make one it would be like this. I'm not sure what happened to Doug, his website (and plans) seems to have gone off the radar. Seems to me I had drawings but maybe I'm mistaken with something else. He made some nice stuff. Some of us could probably reverse engineer it in CAD if there was interest in a group project.

This was the first time using this tool.

I use to have and old used and worn bump style tool with fine/medium/course knurls on the head. If I paid homage to the appropriate gods, and performed some sacrificial rites, it might turn out. So I decided to stop screwing about and got the Accu-Trak.

It worked perfectly.

I use to have and old used and worn bump style tool with fine/medium/course knurls on the head. If I paid homage to the appropriate gods, and performed some sacrificial rites, it might turn out. So I decided to stop screwing about and got the Accu-Trak.

It worked perfectly.

Very nice. Have you been pleased with that knurling tool?

I debate if I should buy a better one, make one like Craig did, or maybe I need to learn more about using the one I have.