-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Follow Rest for Standard Modern

- Thread starter thestelster

- Start date

No to roller bearings. Maybe if I was turning at high speeds, but I won't be. Apparently they'll trap bits of swarf and imprint them on the surface of the material being turned.Roller Bearings?

No to roller bearings. Maybe if I was turning at high speeds, but I won't be. Apparently they'll trap bits of swarf and imprint them on the surface of the material being turned.

I see. I can't really argue. Mine has roller bearings on both the steady and the follow rests. They are factory original. I've never experienced that, but I don't really use follow rests that much.

I guess I would have thought that a solid rest would be worse! But I've never used a solid rest so can't say for sure.

Interesting.

No to roller bearings. Maybe if I was turning at high speeds, but I won't be. Apparently they'll trap bits of swarf and imprint them on the surface of the material being turned.

Possibly, I didn't experience that. The problem with rolling element bearings is it takes a tiny bit of force to get them turning. That'll take you out a thou or two. If you are striving for accurate work, bronze is the way to go, or at least I've not found it wanting. It takes a bit of practice on the touch when using the travelling steady - you engage the fingers while things are moving after things have gone past the tailstock, that's where the touch comes in.

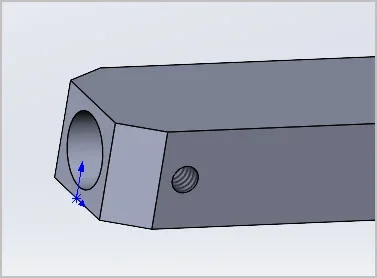

My DSG came with needle bearing rollers. I put new bearings in but it still wasn't sensitive enough. So finally I made the bronze fingers., photos of each on the previous mage

Peter, I wouldn't silver solder, it'll soften the bronze. Soft solder should be good enough. I just loctited some small bars in a steel housing to minimize the bronze consumption

Last edited:

Good point on soldering.

Actually balls might be unnecessarily complicated. Maybe you could just drill a blind hole in the end of a finger, insert a section of bronze rod, retain it laterally with a set screw or whatever. The bronze could be customizable - tapered for smaller part stock, ball ended...

Actually balls might be unnecessarily complicated. Maybe you could just drill a blind hole in the end of a finger, insert a section of bronze rod, retain it laterally with a set screw or whatever. The bronze could be customizable - tapered for smaller part stock, ball ended...

Attachments

Last edited:

That's exactly what I was planning!! Simple, versatile, and cheap!Good point on soldering.

Actually balls might be unnecessarily complicated. Maybe you could just drill a blind hole in the end of a finger, insert a section of bronze rod, retain it laterally with a set screw or whatever. The bronze could be customizable - tapered for smaller part stock, ball ended...

DPittman

Ultra Member

Wouldn't Teflon be much too soft and not really provide support?TEFLON. Or babbit

Former Member

Guest

As a quick comparison, different brands for similar Lathes have different selections with the main 2 being either a steel finger with a bronze contact point (replaceable or fixed?) or steel finger with a roller end (bearing or not).

Traditional would be solid, tried and true.

Modern being roller end.

I think the choice comes down to load and speed. Higher speed means rollers vs solid. At lower speeds and I suspect higher loads solid points.

As to precision I suspect solid being the choice.

Traditional would be solid, tried and true.

Modern being roller end.

I think the choice comes down to load and speed. Higher speed means rollers vs solid. At lower speeds and I suspect higher loads solid points.

As to precision I suspect solid being the choice.

Proxule

Ultra Member

Not sure, I seen the old timer at the sawmill use it often, He did have spares setup. I never asked how long it lasted.Wouldn't Teflon be much too soft and not really provide support?

I know it has a very high melting point !

I was curious to your question, Seems others do it too?!

we use teflon PTFE on ours steady rest that is not taking heavy load (under 1000 pounds) it is way more wear resistant than bronze 660 and is going to take the heat anytime. ive put them on my steady rest 2 year ago and never see the shape change after all these year (ive use them 2 to 3 time a week) its kinda expensive but it worth it. just put some bardall on them before you put the shaft in the steady rest and it will go like a charm (or any kind of oil that is thick enought to stay on them)

Post #11 https://www.practicalmachinist.com/forum/threads/steady-rest-jaws-babbitt.251003/

Now to put this beast on a diet!

Of course it's to big to make a single cut, so I had to flip it. And I just aligned it by eye. I lucked out.

Why didn't you just cut it with an OA Torch?

#1-I don't have oxy-acet, nor plasmaWhy didn't you just cut it with an OA Torch?

#2- that's 1"thick, 10" cut, haven't a clue how long it would take, and the air pollution in my garage!!?

#3-let the saw cut while I do other stuff.

#1 & #3 make sense.#1-I don't have oxy-acet, nor plasma

#2- that's 1"thick, 10" cut, haven't a clue how long it would take, and the air pollution in my garage!!?

#3-let the saw cut while I do other stuff.

#2 doesn't. OA will cut 10" of 1" plate like butter. Just need the right size cutting tip for the plate thickness and a relatively steady hand. I dunno, maybe a minute? Once you get the cut going, it goes pretty fast.

Main advantage is ability to cut curves. I'm not that good at it, but it's amazing to watch someone who is.

Of course a plasma table will do it even better.

watch some of I C welds videos on youtube. His OA torch cuts look like they were milled out.Of course a plasma table will do it even better.

watch some of I C welds videos on youtube. His OA torch cuts look like they were milled out.

Ya, but I am no torch wizard. I'll be dead before I ever get that good!

FWIW, I don't have plasma. I just wish I did. Instead I make do with OA cuts that are a bit rough.

I'm happy though, cuz OA is fast and very flexible.