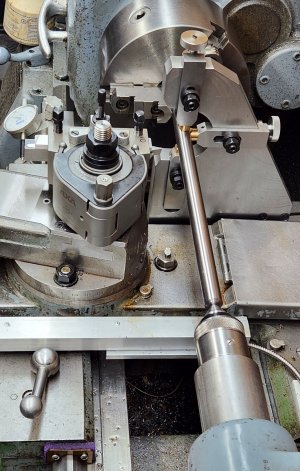

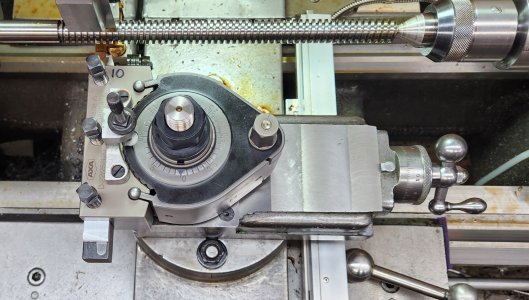

Its worth making a new nut because a) looks like you need one anyways b) you will be able to better quantify your leadscrew wear c) its less work. Thread the nut to position X, pull forth & back, measure backlash with DTI, move to next position X, rinse & repeat. Compare to your existing worn nut. You may find negligible wear or you may find localized wear but either way be in a better position to assess if you can run the leadscrew as-is or make another.

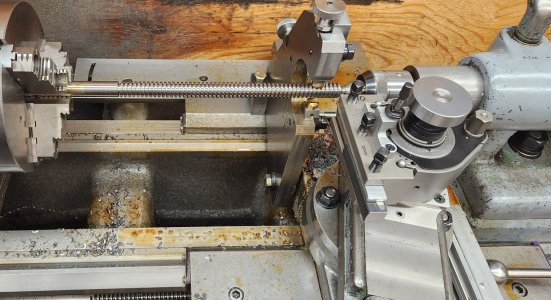

I saw a guy splice a new leadscrew threaded segment using a donor section from his existing screw, but if I recall, it had some funky threads or splines he was not in a proper position to replicate. But yours looks more straightforward. Or make a new one & flog your existing one on Ebay, there are always people looking for plug-n-play.

I saw a guy splice a new leadscrew threaded segment using a donor section from his existing screw, but if I recall, it had some funky threads or splines he was not in a proper position to replicate. But yours looks more straightforward. Or make a new one & flog your existing one on Ebay, there are always people looking for plug-n-play.