That makes sense the way you describe it. I'll have to check how much room I have to accommodate longer length nuts in there. My actual ABL nut split segment is even thinner than I proposed. Its definitely worn, I assumed because of the non-symmetrical way its loaded with the single set screw. My leadscrew is also worn in the common use area but not as much as the nut (when leadscrew was checked against a new nut). Someone once told me its inevitable, you might install 3 nuts per leadscrew but the leadscrew will always wear to some degree. Not sure if that was from experience or Asian lathes or where that came from

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cross-Slide Leadscrew & Nut

- Thread starter thestelster

- Start date

I know Thestelster is pursuing this in part for the challenge, but from a strictly practical standpoint, don't get discouraged if your lathe feedscrew has lots of wear and backlash. For accuracy, feedscrew wear and backlash don't really matter much on a lathe. Wear because you are not measuring over large distances and backlash because you are operating in one direction. I think the main reason backlash gets so much attention is that when evaluating a lathe, excessive amounts are indicative of the general level of wear.....but the backlash itself is not much of a problem. otoh having everything tight and new is nice and I have made feedscrews several times for lathes ...... so no objection to doing so, just saying if you've got one in poor shape, it shouldn't stop you from doing good work. Here's an extreme example, my first lathe. Still, I made a couple of model engines on it before upgrading.

Holy cow!! Is that lead screw made out off cheese?!I know Thestelster is pursuing this in part for the challenge, but from a strictly practical standpoint, don't get discouraged if your lathe feedscrew has lots of wear and backlash. For accuracy, feedscrew wear and backlash don't really matter much on a lathe. Wear because you are not measuring over large distances and backlash because you are operating in one direction. I think the main reason backlash gets so much attention is that when evaluating a lathe, excessive amounts are indicative of the general level of wear.....but the backlash itself is not much of a problem. otoh having everything tight and new is nice and I have made feedscrews several times for lathes ...... so no objection to doing so, just saying if you've got one in poor shape, it shouldn't stop you from doing good work. Here's an extreme example, my first lathe. Still, I made a couple of model engines on it before upgrading.

View attachment 44300

You know... I wonder if sometimes we tighten up the gibs so much, to reduce chatter, or vibrations or play, that it puts excessive pressure on the flanks of the threads causing the wear??

It's out of a Standard Modern so should be decent screw steel (which is of course soft) There was wear everywhere. I think gib tightening would affect the gib/dovetail more, maybe excessive use of a pressure knurler? My best guess is a long life of abrasives, maybe grinding or far worse, sanding. But i'm guessing, don't know for sure.

Last edited:

It's out of a Standard Modern so should be decent screw steel (which is of course soft) There was wear everywhere. I think gib tightening would affect the gib/dovetail more, maybe excessive use of a pressure knurler? My best guess is a long life of abrasives, maybe grinding or far worse, sanding. But i'm guessing, don't know for sure.

You have just opened my eyes to something I have not considered before.

I always cover my ways and methodically clean everything during and after grinding or using emery cloth. But I have not been protecting or cleaning my screws. That changes effective immediately.

Thank you for that!

I know Thestelster is pursuing this in part for the challenge, but from a strictly practical standpoint, don't get discouraged if your lathe feedscrew has lots of wear and backlash. For accuracy, feedscrew wear and backlash don't really matter much on a lathe. Wear because you are not measuring over large distances and backlash because you are operating in one direction. I think the main reason backlash gets so much attention is that when evaluating a lathe, excessive amounts are indicative of the general level of wear.....but the backlash itself is not much of a problem. otoh having everything tight and new is nice and I have made feedscrews several times for lathes ...... so no objection to doing so, just saying if you've got one in poor shape, it shouldn't stop you from doing good work. Here's an extreme example, my first lathe. Still, I made a couple of model engines on it before upgrading.

View attachment 44300

Looks about the same condition as the SM 1120 that I repaired. There didn't appear to be a way to oil the screw/nut. After i made the new parts, I bored the securing bolt for an oiler.

Oddly enough the rest of the machine was in great condition.

Last edited:

I think a typical cross slide leadscrew is well protected from most debris. They should be oiled regularly. My lathe has an oiler nipple directly over the screw in close proximity to the nut. I just use the same way oil as the other oilers. But wear is wear. You are sucking those threads together over & over thousands & thousands of times, probably 90% within the same 3" linear range depending on the work you. The bronze is typically softer, it preferentially wears, makes a slurry not unlike a low grade lapping compound. Ordinary cutting infeed forces shouldn't be too bad & provide years of service, but this is why I refuse to bump knurl. The wear & tear over other knurling methods isn't worth it.

I was able to get another lead screw & nut when I rebuilt my lathe a few years back. Personally if I ever bought a new lathe I would add some specific spares onto the order, pack them away & consider these as consumable items. Depending on the lathe, swapping in new might be a lot easier than re-making from scratch although as discussed, there may be some improvements one could make over factory items. Same goes for certain (power feed) gears in the apron drive train, threading clam shells... they can be shop made but may not exactly trivial to replicate. The cost is reasonable when available. The problem is when they are unavailable.

I was able to get another lead screw & nut when I rebuilt my lathe a few years back. Personally if I ever bought a new lathe I would add some specific spares onto the order, pack them away & consider these as consumable items. Depending on the lathe, swapping in new might be a lot easier than re-making from scratch although as discussed, there may be some improvements one could make over factory items. Same goes for certain (power feed) gears in the apron drive train, threading clam shells... they can be shop made but may not exactly trivial to replicate. The cost is reasonable when available. The problem is when they are unavailable.

If you were buying an offshore machine, buying spares at the time of purchase would make sense. They'd be a hell of a lot cheaper, than say from SM/Racer, and also so that you'd be more certain of getting the correct parts vs 10-20 years down the road.

When I got the quote from Racer for a steady rest for my 1660 I almost keeled over....3800usd if i recall. Buying spare parts at the time of purchase probably wouldn't be feasible.

Now if you took the brand new machine and copied some of the wear parts before they were worn...

When I got the quote from Racer for a steady rest for my 1660 I almost keeled over....3800usd if i recall. Buying spare parts at the time of purchase probably wouldn't be feasible.

Now if you took the brand new machine and copied some of the wear parts before they were worn...

Last edited:

Tom O

Ultra Member

You could have it in 3 pieces if you wanted to instead of just one on the end.Yes Peter, that is one of the many design principles I looked at in the past. I don't really like it though. It's too prone to failure of the thinner nut - especially if adjusted too tightly.

I much prefer the double large nuts on slider pins design. But we don't have that option on machines not designed for it. Or perhaps I should say that I just don't know how to do it.

You could have it in 3 pieces if you wanted to instead of just one on the end.

I've never seen a 3pc nut. What does that do for you that a 2pc doesn't?

I'm starting to like the (entire) split & squeeze mode. It seems like the wear would be more evenly applied to much more thread contact area. I would think increment adjustment would be very fine though but obviously it works on @Darren machine. Presumably the thread type is common angle or maybe there is some non-standard optimization there?

Motion control using screws

www.notesandsketches.co.uk

Tom O

Ultra Member

I just thought that by having one on both ends you’d have twice the contact on the ends but after thinking about it it wouldn’t be worth it.I've never seen a 3pc nut. What does that do for you that a 2pc doesn't?

Hi @Ironman thank you for the compliment. I'm not sure I resemble a good machinist, but you made my day.As you are thestelster, and a good machinist, I suspect you want to do it in bronze, but this may help someone else.

Interesting article. I would think that the leadscrew threads should be in good condition so the acetal nut forms to it consistently. But I do plan on using 1144 Stressproof for the leadscrew, and C95400 aluminium bronze for the nut.

I'm not sure I resemble a good machinist,

In my books you are.

I must rescind or at least modify my claim that cross slide feedscrew backlash doesn't matter.

One case where it does matter is when using the telescoping type of taper attachment; where the nut is not disconnected and you still use the crossfeed dial. You end up with the taper attachment wanting to pull the crosslide away the advancing thread flank and any backlash will mess you up.

These need an anti backlash nut.

Feedscrew backlash doesn't matter is still valid otherwise and when using a telescoping taper attachment, no back lash is permitted. i.e. 10 thou is a bad as 50 thou backlash. My DSG has such an arrangement and while slick, I leave it set with a bit of backlash figuring having it all tightened up would lead to faster wear. Makes it a pita as I have to do so when cutting tapers, but that is quite rare and sometimes I cheat and snug up the gib, but there's an example feedscrew backlash mattering

One case where it does matter is when using the telescoping type of taper attachment; where the nut is not disconnected and you still use the crossfeed dial. You end up with the taper attachment wanting to pull the crosslide away the advancing thread flank and any backlash will mess you up.

These need an anti backlash nut.

Feedscrew backlash doesn't matter is still valid otherwise and when using a telescoping taper attachment, no back lash is permitted. i.e. 10 thou is a bad as 50 thou backlash. My DSG has such an arrangement and while slick, I leave it set with a bit of backlash figuring having it all tightened up would lead to faster wear. Makes it a pita as I have to do so when cutting tapers, but that is quite rare and sometimes I cheat and snug up the gib, but there's an example feedscrew backlash mattering

Last edited:

It can't really work the way you describe (if I understand). The big threaded block is attached to the slide. The smaller threaded ring floats, buts its pulling the leadscrew to the left, taking up any leadscrew backlash within the big block threads. If you had another ring on the right with wave washers it would work against the ABL action of the left... unless it was somehow sprung to also push left, but that's getting complicated.I just thought that by having one on both ends you’d have twice the contact on the ends but after thinking about it it wouldn’t be worth it.

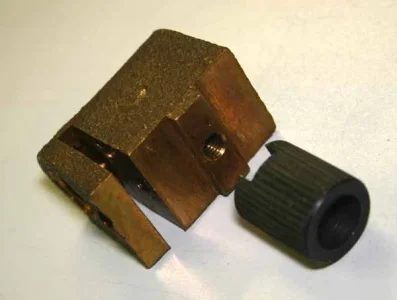

View attachment 44348

If the ring washer were thicker, it would see reduced wear to its threads, so some benefit there. But as discussed & shown, wear is going to occur somewhere regardless, we are just trying to confine it to the easier-to-replace part.

I just received the material for the crossfeed screw and nut. 6 feet of AISI 1144 3/4" tight tolerance rod. (I only wanted 3 feet, but delivery time was 10 weeks, but the six footer, next day delivery!) And 1.5" x 1.5" x 12" C95400 aluminium bronze.

I need a few more things, and maybe I can start next week.

I need a few more things, and maybe I can start next week.