-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What's Paul up to?

- Thread starter PaulL

- Start date

Lost in the Great Crash of '23, but not lost to my shop. I got the Harold Hall grinding rest pretty much completed today, with a little holder to take my QCTP holders and orient them to the wheel appropriately:

The little block of mystery metal accepted the dovetail well, but seriously chewed up my drill bits. One happily shattered while drilling the hole to hold the block in the slot. That's the reason the grub screw to hold the dovetail to the holder is 3mm instead of something a bit bigger - my 13/64th (M5 tapping size) bit no longer exists. Yay?

But it works, and I'm surprised how much better the surface finish is on my turnings with the tool sharpened a little more carefully than I had been before I had such a handy rest.

I'll probably remake it when I find a piece of mild steel large enough for the task - I'd much rather cinch the tool holder to the table from above than from below with a hex key. And there's no hope I can get that hole drilled in this stuff!

Mystery metal for the win!

Paul

The little block of mystery metal accepted the dovetail well, but seriously chewed up my drill bits. One happily shattered while drilling the hole to hold the block in the slot. That's the reason the grub screw to hold the dovetail to the holder is 3mm instead of something a bit bigger - my 13/64th (M5 tapping size) bit no longer exists. Yay?

But it works, and I'm surprised how much better the surface finish is on my turnings with the tool sharpened a little more carefully than I had been before I had such a handy rest.

I'll probably remake it when I find a piece of mild steel large enough for the task - I'd much rather cinch the tool holder to the table from above than from below with a hex key. And there's no hope I can get that hole drilled in this stuff!

Mystery metal for the win!

Paul

Lost in the Great Crash of '23, but not lost to my shop. I got the Harold Hall grinding rest pretty much completed today, with a little holder to take my QCTP holders and orient them to the wheel appropriately:

View attachment 29278

The little block of mystery metal accepted the dovetail well, but seriously chewed up my drill bits. One happily shattered while drilling the hole to hold the block in the slot. That's the reason the grub screw to hold the dovetail to the holder is 3mm instead of something a bit bigger - my 13/64th (M5 tapping size) bit no longer exists. Yay?

But it works, and I'm surprised how much better the surface finish is on my turnings with the tool sharpened a little more carefully than I had been before I had such a handy rest.

I'll probably remake it when I find a piece of mild steel large enough for the task - I'd much rather cinch the tool holder to the table from above than from below with a hex key. And there's no hope I can get that hole drilled in this stuff!

Mystery metal for the win!

Paul

I LOVE THIS PAUL!

Officially added to my future project list. Might even use aluminium for the holder block..... LOL!

I wish I had tracked it. It's been a side project in the shop for a couple of months. I'd say I'm 30ish hours in? The more recent hours have been much more productive than the first few. If I had dimensioned my stock intelligently instead of piecemeal I'm pretty sure I could have spent 8-10 hours less.Hey Paul do you have any idea how much time you have in the Harold Hall grinding rest?

It looks great. I’ve been thinking about one for some time.

Do you think the design is good as it is?

Art

I like the design. I have to remake the angle iron base - I used what I had on hand and it's too flimsy, letting the whole thing vibrate. The top plate will likely also be re-made once I know how I use it - using my QCTP holder on it, for example, doesn't fit well with Mr. Hall's jigging. An auxiliary table could fix it, or I could just have different tables for different uses.

As a begining milling project it was just about right - few things too critical - and it's already showing its value in my shop.

Last edited:

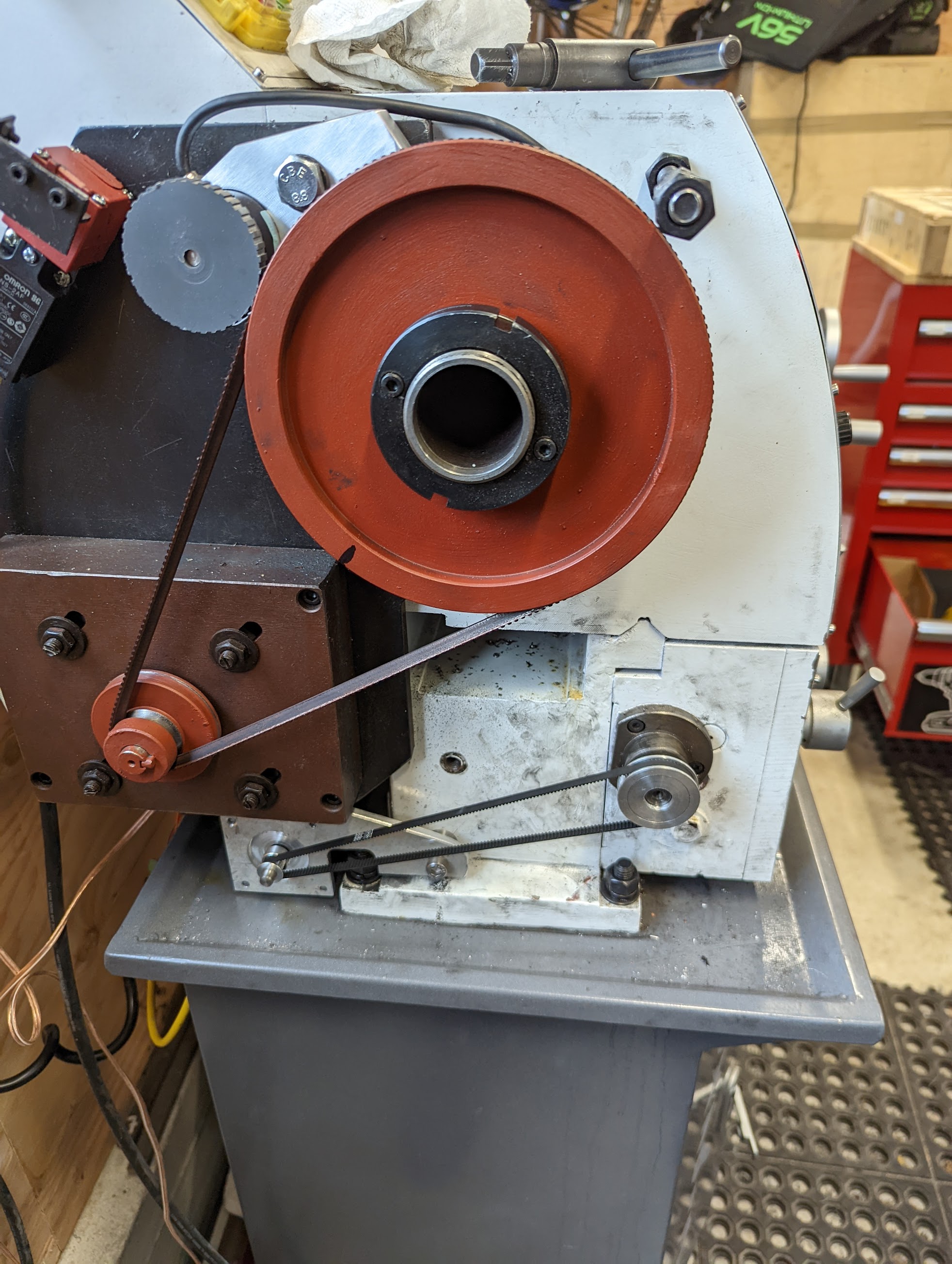

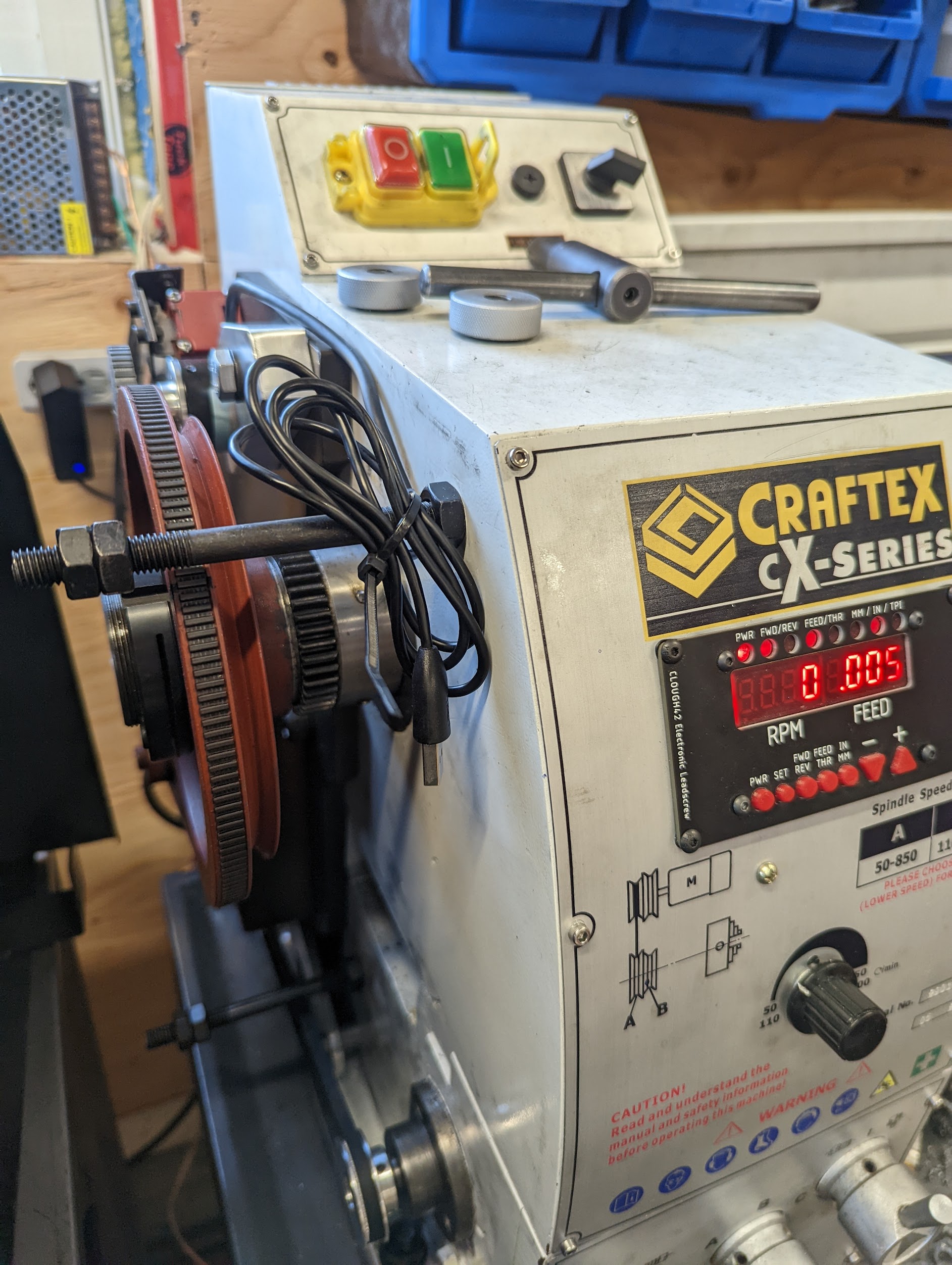

I noticed that my nice tidy lathe pictures died in the Great Crash of '22. I happened to have the post open in another window...

And I managed that Christmas Morning shop time:

She's all tidy and her safety cover is back on.

I just have one detail to fix...When I moved the motor I changed the parity of drive - forward is now reversed! Tomorrow I'll pull the front cover, get at the programming port on the microcontroller and fix it. Until then she runs fine in forward with the drive lever set to reverse!

And since then, I pulled out the programming interface, it's awfully handy having the USB programming port hanging out somewhere accessible.

Paul

And I managed that Christmas Morning shop time:

She's all tidy and her safety cover is back on.

I just have one detail to fix...When I moved the motor I changed the parity of drive - forward is now reversed! Tomorrow I'll pull the front cover, get at the programming port on the microcontroller and fix it. Until then she runs fine in forward with the drive lever set to reverse!

And since then, I pulled out the programming interface, it's awfully handy having the USB programming port hanging out somewhere accessible.

Paul

So I started remaking the jig to hold my QCTP holders to the sharpening jig. And I did have some aluminium on hand, though in awkwardly large sections (4"x4"x40"). So after a long time in a saw with too fine a tooth pattern, I got it mostly squared up, when the oops fairy showed up:

The block turned itself 90 degrees up in the vise, just as I was clearing up the 4th face. The only injury is the 1/2" end mill, which is now running somewhat out of true. And a skipped heartbeat or two.

Aluminium is both *slippery* and *grabby*. Both holding faces were freshly milled, flat and parallel to one another.

Any tips for holding this stuff more securely in the vise?

Paul

The block turned itself 90 degrees up in the vise, just as I was clearing up the 4th face. The only injury is the 1/2" end mill, which is now running somewhat out of true. And a skipped heartbeat or two.

Aluminium is both *slippery* and *grabby*. Both holding faces were freshly milled, flat and parallel to one another.

Any tips for holding this stuff more securely in the vise?

Paul

Former Member

Guest

Quick guess, likely a little heavier than you expect for the size (subjective of course), appears to start to drill nice just before it eats the drill, has a nice shine to it, cuts clean when you can machine it.Lost in the Great Crash of '23, but not lost to my shop. I got the Harold Hall grinding rest pretty much completed today, with a little holder to take my QCTP holders and orient them to the wheel appropriately:

View attachment 29278

The little block of mystery metal accepted the dovetail well, but seriously chewed up my drill bits. One happily shattered while drilling the hole to hold the block in the slot. That's the reason the grub screw to hold the dovetail to the holder is 3mm instead of something a bit bigger - my 13/64th (M5 tapping size) bit no longer exists. Yay?

But it works, and I'm surprised how much better the surface finish is on my turnings with the tool sharpened a little more carefully than I had been before I had such a handy rest.

I'll probably remake it when I find a piece of mild steel large enough for the task - I'd much rather cinch the tool holder to the table from above than from below with a hex key. And there's no hope I can get that hole drilled in this stuff!

Mystery metal for the win!

Paul

Likely a chrome moly steel type.

One word Carbide.

Though nicely done, enjoy.

The block turned itself 90 degrees up in the vise, just as I was clearing up the 4th face. The only injury is the 1/2" end mill, which is now running somewhat out of true. And a skipped heartbeat or two.

Aluminium is both *slippery* and *grabby*. Both holding faces were freshly milled, flat and parallel to one another.

Any tips for holding this stuff more securely in the vise?

Wow! I can feel my heart pounding as if I had been there. But my only experience with that kind of thing on a mill was breaking an endmill when it grabbed. I've been more fussy about which direction I mill in ever since. It's not that I never climb mill, just that I try not to. When I do, I will often partially lock the axis I am milling in, and I always limit the size of my cut.

I am amazed at that pattern on the block. It suggests that things were bouncing pretty badly too! That doesn't happen so easily on such a big mill.

It looks to me like you were climb milling and/or milling in x without locking the Y. If so, I could see this happening more easily. Once the end mill grabbed, the vise would have had a very hard time holding on. Especially given that your part was seated quite shallow in the Jaws. Deeper is always better.

Last but not least, it looks like your part was originally located at one end of the Jaws. No matter how big your vise is, it will bend a bit as the pressure builds. It's not if, it's just how much. Stress causes strain - it's unavoidable. When I mount something in my vise I always try to mount it in the middle. If I can't do that for some reason, then I put something else in the vise at the other end to balance the load a bit. An equally sized part of the same material is best, but even a wood shim on a smaller metal part is better than nothing. If you don't do that, the Jaws will cant ever so slightly. Even an invisible cant in the Jaws will significantly reduce clamping ability.

Last edited:

Former Member

Guest

Lucky it only bent the endmill, I've snapped a 1" one that way and it flies afterwards like a rocket bouncing off anything it hits luckily I wasn't in a part of the path. I'm going to suggest the endmill is toast. Also tram your head to ensure its still true. You be surprised how much force you applied in those brief heart stopping couple of seconds.So I started remaking the jig to hold my QCTP holders to the sharpening jig. And I did have some aluminium on hand, though in awkwardly large sections (4"x4"x40"). So after a long time in a saw with too fine a tooth pattern, I got it mostly squared up, when the oops fairy showed up:

View attachment 29341

The block turned itself 90 degrees up in the vise, just as I was clearing up the 4th face. The only injury is the 1/2" end mill, which is now running somewhat out of true. And a skipped heartbeat or two.

Aluminium is both *slippery* and *grabby*. Both holding faces were freshly milled, flat and parallel to one another.

Any tips for holding this stuff more securely in the vise?

Paul

I agree with @sasquatch when you held the part off center you created the ideal pivot point on the block closet to the center of the vise. Voila!

Just remember the old saying what doesn't kill you makes you smarter and don't make that mistake again 😉.

What RPM were you using? What depth of cut?So I started remaking the jig to hold my QCTP holders to the sharpening jig. And I did have some aluminium on hand, though in awkwardly large sections (4"x4"x40"). So after a long time in a saw with too fine a tooth pattern, I got it mostly squared up, when the oops fairy showed up:

View attachment 29341

The block turned itself 90 degrees up in the vise, just as I was clearing up the 4th face. The only injury is the 1/2" end mill, which is now running somewhat out of true. And a skipped heartbeat or two.

Aluminium is both *slippery* and *grabby*. Both holding faces were freshly milled, flat and parallel to one another.

Any tips for holding this stuff more securely in the vise?

Paul

A zoom in on the freshly milled holding surfaces suggests they are not super smooth. if the vise wasn't clamped hard enough the actual holding surface was quite small.

Based on the markings I'm trying to figure out where it was clamped in the vise. On the end where it is now and you started milling where the cutter is sitting? Then the others are correct. Your vise also flexed and you were really only pinching it on the RH corner. Not enough to hold it well.

Definitely hits the "a little heavier than expected", and the nice-until-bad.Quick guess, likely a little heavier than you expect for the size (subjective of course), appears to start to drill nice just before it eats the drill, has a nice shine to it, cuts clean when you can machine it.

Likely a chrome moly steel type.

One word Carbide.

Though nicely done, enjoy.

Still going to replace it. Those carbide drills are spendy!

It wasn't particularly bouncy - each of those streaks is one edge of the cutter grabbing and pulling!I am amazed at that pattern on the block. It suggests that things were bouncing pretty badly too! That doesn't happen so easily on such a big mill.

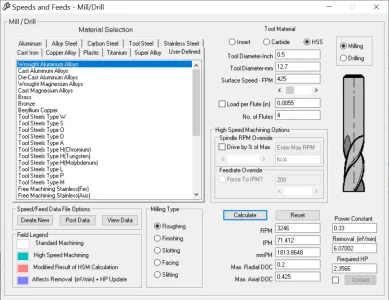

Yes, not super-smooth. The end mill was a bit ratty to start. Was running slower than I should have been (~1200rpm, vs the 6k rpm the usual charts propose for a 1/2 end mill in aluminium), and maybe feeding too fast.A zoom in on the freshly milled holding surfaces suggests they are not super smooth.

I was absolutely clamped at the end, expecting to mill the end of the blank in the same setup. And I was in too-high parallels, instead of changing them out between facing the edges vs faces.

Lesson learned, I hope.

Paul

It wasn't particularly bouncy - each of those streaks is one edge of the cutter grabbing and pulling!

Ah yes, zooming in, I can see that now. In fact I can see it in slow mo in my mind...... It ain't pretty! LOL!

Was running slower than I should have been (~1200rpm, vs the 6k rpm the usual charts propose for a 1/2 end mill in aluminium), and maybe feeding too fast.

I was absolutely clamped at the end, expecting to mill the end of the blank in the same setup. And I was in too-high parallels, instead of changing them out between facing the edges vs faces.

In my (very limited) experience, that big machine should have handled that low speed albeit obviously not optimum.

6000 rpm? Will your machine go that fast? My factory top speed is 2750. With the VFD I installed, it will do 4500 safely but I would prolly never run that fast anyway.

Ya, clamping at the end of the jaws without a counter load on the other side, plus climb milling is what did it. I am of the view that your finish, while not perfect, should have held.

FWIW, I have an old set of sine blocks and a few 4x1x1/4 hardwood blocks that I keep beside my mill and drill press to use whenever I feel the need to mount something on the left or right side of my jaws.

You aren't the first or likely the last to bend a tool for one reason or another.

I have a bunch of things I've bent or broken over the years too. I keep them to remind me not to do whatever it was again.

Whenever I use this tool I consider the feed rate at the high end for production rather than home hobby.

That's pretty impressive. It's prolly way more info than I'll ever use but who knows.....

I have a chart on the wall behind my lathe with graphs for some stuff like that. I hardly ever use it either.

Is that a Windows or a Mac program? Is there an android version?