-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What's Paul up to?

- Thread starter PaulL

- Start date

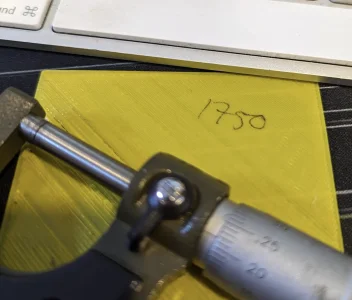

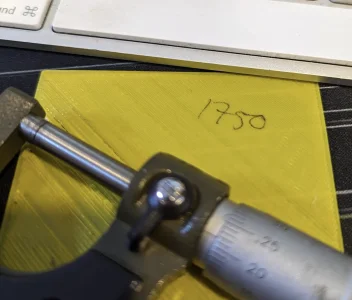

You are welcome to look at my South Bend draw tube.And now with a draw tube my first measurement is about 8 10ths. Still no way to bear down on the draw tube - I need to figure out a thrust washer and a bushing to the spindle bore.

I'm encouraged.

View attachment 42780View attachment 42781

Well, here we go.

It was an ugly drive down the mountain from Coquitlam yesterday, but made it home in one piece.

Got to figure out why Y was slipping, and got to re-adjust the PINDA sensor height, which was much too low, but it looks like printing is starting to happen.

Lots of calibration squares to get there:

Also seeing a funny smear on X when starting, visible (left) on the prusa logo, and (right) on the boat, but it's starting to feel like progress:

It was an ugly drive down the mountain from Coquitlam yesterday, but made it home in one piece.

Got to figure out why Y was slipping, and got to re-adjust the PINDA sensor height, which was much too low, but it looks like printing is starting to happen.

Lots of calibration squares to get there:

Also seeing a funny smear on X when starting, visible (left) on the prusa logo, and (right) on the boat, but it's starting to feel like progress:

Hey, older bro is a computer genius, not great with any tools other than a soldering iron, wirewrap gun, or CodeWarrior. If you need a satellite downlink built, he’s your guy. Changing lightbulbs? Not so much.Well, here we go.

It was an ugly drive down the mountain from Coquitlam yesterday, but made it home in one piece.

Got to figure out why Y was slipping, and got to re-adjust the PINDA sensor height, which was much too low, but it looks like printing is starting to happen.

Lots of calibration squares to get there:

View attachment 42848

Also seeing a funny smear on X when starting, visible (left) on the prusa logo, and (right) on the boat, but it's starting to feel like progress:

Ok, looks like it was the fillament catching on the enclosure tugging on the extruder head. So a bit of work to figure out how to feed the fillament better. You'd think this would all be settled technology, but it appears not!Also seeing a funny smear on X when starting,

Looking good.

Damn, I hate it when my extruder head gets tugged.Ok, looks like it was the fillament catching on the enclosure tugging on the extruder head. So a bit of work to figure out how to feed the fillament better. You'd think this would all be settled technology, but it appears not!

Sorry, I'll shut up now.

And all the pulley wheels have now been re-intalled correctly - first set the screw to the flat, then the cross-lock screw. Both X and Y were experiencing small amounts of backlash from wobbling on the shaft.

Nice clean calibration part: height within 0.02mm, X and Y both about 0.05mm/cm. I didn't particularly pay attention to thermal expansion in the slicer or in "generic PLA" parameters, so I'm reasonably pleased with that.

Nice clean calibration part: height within 0.02mm, X and Y both about 0.05mm/cm. I didn't particularly pay attention to thermal expansion in the slicer or in "generic PLA" parameters, so I'm reasonably pleased with that.

Fun huh?And all the pulley wheels have now been re-intalled correctly - first set the screw to the flat, then the cross-lock screw. Both X and Y were experiencing small amounts of backlash from wobbling on the shaft.

Nice clean calibration part: height within 0.02mm, X and Y both about 0.05mm/cm. I didn't particularly pay attention to thermal expansion in the slicer or in "generic PLA" parameters, so I'm reasonably pleased with that.

I meant that in a good way @SusquatchFun huh?

I meant that in a good way @Susquatch

We only have so many emoticon choices. I can only choose one. I used the angry emoticon to convey my disappointment over how difficult the technology is after such a long period of time. I want turn key and its just not prime time yet. I've decided to put a 3D printer on hold for at least another year.

At the high end I'm sure it's pretty good now. At the hobbyist end I think it's still fairly artisanal.We only have so many emoticon choices. I can only choose one. I used the angry emoticon to convey my disappointment over how difficult the technology is after such a long period of time. I want turn key and its just not prime time yet. I've decided to put a 3D printer on hold for at least another year.

At the high end I'm sure it's pretty good now. At the hobbyist end I think it's still fairly artisanal.

You might be right. Sounds logical anyway.

Where would you draw the line between those two categories? Better yet, what is the bottom end of the high end?

I'm guessing somewhere between the price for a bench top mill and a knee mill. It feels like the market is in about the same place.You might be right. Sounds logical anyway.

Where would you draw the line between those two categories? Better yet, what is the bottom end of the high end?

The awkward part about printing is how much ancillary crap there is - filament spools, dryers, vacuum-pack filament cases, etc. Then you get enclosures and air filters and multi-material heads and ... it just keeps on going.

I hope I'm not sounding negative. But as far as I know there aren't any CNC milling machines out there that take a 3D STL drawing and can automatically set up the raw stock and machine it automatically. To get to the point of taking a drawing, creating CNC G-Code, setting up the machine with the tooling and work holding and then machining it all automatically doesn't exist. And if it did it would be way out my price range.

Even the ability to design out of metal, machine and put together something like this in metal at the moment is outside my abilities. The spur gears I can do. The ring gears I've not yet got the setup for that.

And I believe the learning curve for 3D printing is way lower than metal working.

My 2 cents.

Even the ability to design out of metal, machine and put together something like this in metal at the moment is outside my abilities. The spur gears I can do. The ring gears I've not yet got the setup for that.

And I believe the learning curve for 3D printing is way lower than metal working.

My 2 cents.

Really? If you're already really comfortable with software flows, maybe?And I believe the learning curve for 3D printing is way lower than metal working

I agree, much easier to produce a satisfactory print than a satisfactory metal part.Really? If you're already really comfortable with software flows, maybe?

Well to start with you can download any number of 3D printable items and learn how to slice and print them. All without breaking much. No CAD required.Really? If you're already really comfortable with software flows, maybe?

Clamp a piece of aluminum and start milling. Oh wait. Is it 6061? What size cutter? What spindle speed? What feed speed? I want to do a circle and for that I need to move both X and Y, how do I do that and make a decent circle. AH. I need CAD. Can I get turnkey CAD for $300 plus $20 for a spool of filament.

The point I'm trying to make is 3D printer is an order of magnitude easier to get started with than CNC machining. And even after you learn CAD with the 3D parametric model like Fusion360 or AlibreATOM etc. that's just the drawing which can be exported as a STEP file. Now you have to learn the CAM system.

Wow. That's totally opposite my expectations! Going to go poke this printer again.I agree, much easier to produce a satisfactory print than a satisfactory metal part.

I

Think the disconnect is that I know *exactly* what the lathe or milling machine is doing. With the 3d printer it's much more fire and forget. Or maybe fire and pray.Wow. That's totally opposite my expectations! Going to go poke this printer again.