What is the diameter size difference between the straight section of the collet and the tube? You can't rely on the short tapered section only to keep your TIR low. I have a 5C collet chuck for the lathe, and if you go to install a collet into the chuck even minutely crooked, it will bind. The tapered section is really only to squeeze down on the tool.I have myself a post-christmas present of 5C collets. Figured I needed a chuck/adapter for them so I spent the day making this adapter to my lathe's MT5 spindle:

I'll make up the draw tube to go with it next week once I find appropriate pipe.

I'm of two minds about it: it's certainly a learning experience in cutting tapers and concentricity. But I'm only getting to about 3 thou TIR on the bore when popping it out and back in, even when aligning it exactly the same with the spindle (not that it should matter if I made it right...). I don't feel any movement when seated, and it takes a significant tap to pull it out. Blueing shows decent contact over the front third to half of the taper, which is probably short. I matched the angle to an other MT5 taper I have on hand using the compound, maybe I wasn't accurate enough?

I'm guessing there's more accuracy to be gained but that realistically this is the kind of tool that can only be made well with a grinder setup to finish.

I guess I understand why folks buy the chucks for these!

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What's Paul up to?

- Thread starter PaulL

- Start date

I hit that dimension pretty well - sliding fit with just minimal play - I have to tap out the collet, I can't just pull it out by finger strength, but it slides home just fine.What is the diameter size difference between the straight section of the collet and the tube?

I'll know better how it seats once I get the draw tube made. For now the area of concern is run out against the inner tapered bore, which indicates a problem with my MT5 I think.

Yeah - I'm actually thinking of setting it up in the four jaw and taking another thou off the taper much more slowly to improve the finish.maybe a good polish might take out some of the high spot and correct some of the runout.

I think I'll also set the compound with a bit of trig instead of copying the taper - I don't trust my centerline finding plus "no movement" as much as I trust a DTI to measure the travel.

Another thing I found while reviewing my work is that the gib on my cross-slide was mighty loose - I wouldn't be surprised to see some variance coming from there.

Chasing zeros for the win!

Well, that was fun. Scrapped the part. Indicated in the travel to 3 digits plus eyeballed the next figure, and somehow cut a steeper cone.I think I'll also set the compound with a bit of trig instead of copying the taper - I don't trust my centerline finding plus "no movement" as much as I trust a DTI to measure the travel.

On reflection it was a dumb mistake: The compound travels the hypothenuse, not the run. When I did the 20 degree internal taper I worked it out against the hypothenuse - sin(10 degrees) - which let me travel the inch with my compound moving exactly one inch. I used the number from the morse taper table the same way, but it's against a run, not the hypothenuse.

Applied trig has me making the same kinds of errors I made in high school.

Next day in the shop I'll start again.

What you could try is to turn the outside of your adapter, but make it longer at the small end by an inch or so. Drill and tap the small end for 1/2"-13. Make a draw bar to pull the part into your lathe spindle bore. Put a witness mark on the outside of your part so youre always putting it back in the same orientation. Then machine the part for the 5C collet. So you're doing everything in situ. Then remove your adapter and cut off that threaded section. So now your adapter will be as accurate as your lathe spindle. Any runout now will be due to the collet. (NB. If your lathe is cutting a taper when using a chuck, no tailstock, then you might have zero run-out at the mouth of the collet, but will be off several inches away.)

That's clever. I was worried that I was relying entirely on my MT5 seating when doing the 5C features. This will helpDrill and tap the small end for 1/2"-13. Make a draw bar to pull the part into your lathe spindle bore.

Applied trig has me making the same kinds of errors I made in high school.

Next day in the shop I'll start again.

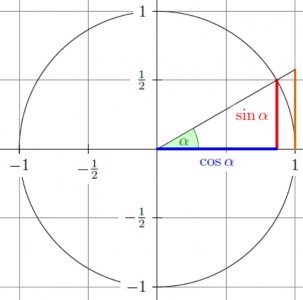

Don't be too hard on yourself. I have forgotten more math than the vast majority ever knew. But I have always had a crappy memory. I always have to do a very simple test to remind myself which one to use. Just draw a simple 30 degree triangle anyplace. Use a calculator to find the sin of 30 which is 0.5. Similarly, the cos is 0.866 . It's easy to see which is which on the triangle. Now you can substitute any angle and know which is which. No need to remember anything.

On the graph above you can easily see that the run of the 30 degree triangle is longer than the rise. So the rise must be the Sine and the run must be the cosine.

I tried to find a better drawing on the interweb but failed. That is shocking to me. It suggests that most people don't know my little trick. But now you do. I hope it helps you even half as much as it has helped me.

Doggggboy

Ultra Member

This picture is gonna be my new screen saver at Christmas.The weather has been properly wet th last few days, and it's New Year's eve. That can only mean one thing. Time to take care of the burn pile.

This is scrap from a cedar that came down two years ago and the last of the form wood scraps from the shop build.

Happy New Year all!

Yes, I know this stuff forward and backwards (my career as built as an engineer implementing real-time 3D graphics in software and hardware...there's really no excuse).On the graph above you can easily see that the run of the 30 degree triangle is longer than the rise. So the rise must be the Sine and the run must be the cosine.

It was a moment of inattention to the rise/run vs angle/hypothenuse.

Anyways, I have enough stock to try again today, including a couple of process improvements that came to me last night looking at the job again. Probably take half the time and come out much better.

So today I got to cutting the MT5 taper again. And three cuts in I knew it was wrong, again.

So I did what any sane human would do looking at this and quickly did arcsin(0.0526) and what do you know, that gives 3 degrees and change, not the 1.5 and change I expected. D'Oh. The taper per inch in the table is the overall taper, and the angle given is the half angle.

Even my hypothenuse hypothesis is hysterical: the error is around one part in a thousand given how shallow these angles are.

So now I'm reading the column headings more carefully.

This is made harder by the fact that the taper I'm checking is for the MT5 socket in my lathe, which means pulling (and re-indicating) the part each check. If only I had a second lathe to make this a bit easier. See how easily that starts?

And of course *there is* a second lathe, on the combination machine a friend keeps in my shop. I'll chuck this up in his 4-jaw and that will let me tweak the taper a bit more conveniently, I think.

Right now it's close, but not perfect - I seem to have a slight barreling in the taper. It contacts in a clear ring about half and inch behind the mouth. So I need to figure out how my compound is cutting a barrel. Could this be induced by the tail support I've been using? I didn't have this problem with the previous taper which I cut without tail support.

So I did what any sane human would do looking at this and quickly did arcsin(0.0526) and what do you know, that gives 3 degrees and change, not the 1.5 and change I expected. D'Oh. The taper per inch in the table is the overall taper, and the angle given is the half angle.

Even my hypothenuse hypothesis is hysterical: the error is around one part in a thousand given how shallow these angles are.

So now I'm reading the column headings more carefully.

This is made harder by the fact that the taper I'm checking is for the MT5 socket in my lathe, which means pulling (and re-indicating) the part each check. If only I had a second lathe to make this a bit easier. See how easily that starts?

And of course *there is* a second lathe, on the combination machine a friend keeps in my shop. I'll chuck this up in his 4-jaw and that will let me tweak the taper a bit more conveniently, I think.

Right now it's close, but not perfect - I seem to have a slight barreling in the taper. It contacts in a clear ring about half and inch behind the mouth. So I need to figure out how my compound is cutting a barrel. Could this be induced by the tail support I've been using? I didn't have this problem with the previous taper which I cut without tail support.

Hey Paul, can you show us your set-up?So today I got to cutting the MT5 taper again. And three cuts in I knew it was wrong, again.

So I did what any sane human would do looking at this and quickly did arcsin(0.0526) and what do you know, that gives 3 degrees and change, not the 1.5 and change I expected. D'Oh. The taper per inch in the table is the overall taper, and the angle given is the half angle.

Even my hypothenuse hypothesis is hysterical: the error is around one part in a thousand given how shallow these angles are.

So now I'm reading the column headings more carefully.

This is made harder by the fact that the taper I'm checking is for the MT5 socket in my lathe, which means pulling (and re-indicating) the part each check. If only I had a second lathe to make this a bit easier. See how easily that starts?

And of course *there is* a second lathe, on the combination machine a friend keeps in my shop. I'll chuck this up in his 4-jaw and that will let me tweak the taper a bit more conveniently, I think.

Right now it's close, but not perfect - I seem to have a slight barreling in the taper. It contacts in a clear ring about half and inch behind the mouth. So I need to figure out how my compound is cutting a barrel. Could this be induced by the tail support I've been using? I didn't have this problem with the previous taper which I cut without tail support.

This horror?Hey Paul, can you show us your set-up?

The DTI tucked into the back is just there to ascertain that no, I can't get 26.3 thou of travel out of it.

You can see to the right the section for the 1/2-13 you suggested to hold the MT securely while machining the 5C features. Then, moving left, the over-steep taper, then a flat section I'm using to set my taper *correctly* this time, indicated by the top indicator. Then the holding which will also be the face flange of the finished adapter, once trimmed to more elegant dimension. And then far left, the indicator for my compound travel so I can read off one inch of travel directly.

It "only" took about 30 tries to get it "close enough".

As far as cutting goes, replace the mess of indicators on the cross slide with a QCTP 250-111, and an HSS tool.

So…that’s where all my indicators are! 😀This horror?

View attachment 42660

The DTI tucked into the back is just there to ascertain that no, I can't get 26.3 thou of travel out of it.

You can see to the right the section for the 1/2-13 you suggested to hold the MT securely while machining the 5C features. Then, moving left, the over-steep taper, then a flat section I'm using to set my taper *correctly* this time, indicated by the top indicator. Then the holding which will also be the face flange of the finished adapter, once trimmed to more elegant dimension. And then far left, the indicator for my compound travel so I can read off one inch of travel directly.

It "only" took about 30 tries to get it "close enough".

As far as cutting goes, replace the mess of indicators on the cross slide with a QCTP 250-111, and an HSS tool.

140mower

Don

..... By all indications, there's a work piece in the works.....🙄This horror?

View attachment 42660

The DTI tucked into the back is just there to ascertain that no, I can't get 26.3 thou of travel out of it.

You can see to the right the section for the 1/2-13 you suggested to hold the MT securely while machining the 5C features. Then, moving left, the over-steep taper, then a flat section I'm using to set my taper *correctly* this time, indicated by the top indicator. Then the holding which will also be the face flange of the finished adapter, once trimmed to more elegant dimension. And then far left, the indicator for my compound travel so I can read off one inch of travel directly.

It "only" took about 30 tries to get it "close enough".

As far as cutting goes, replace the mess of indicators on the cross slide with a QCTP 250-111, and an HSS tool.

The taper per inch in the table is the overall taper, and the angle given is the half angle.

I've done many tapers in my life and yet I did the same thing and made the same mistake on my grinding wheel arbour. Why do they do that? In my humble opinion, an overall taper is a totally, completely, and entirely useless number. I feel your pain.

I noticed in my readings that in the 50s, The number you use was called "half taper" and I think people just shortened/forgot to specify. People are generally more lazy than stupid.an overall taper is a totally, completely, and entirely useless number.

Ok, new MT5 taper is now running well.

I skimmed the taper *without* tail support, and that got rid of the slight barrelling I'd detected.

This second time I also left much more nose on to facilitate measuring runout.

Dropped the new taper in, didn't bother with the 1/2-13 drawbar, and cut the nose to concentric. Popped it out, and re-inserted in the same orientation: runout of <1/10th at 1.5" away from the mouth of the spindle taper; even rotating it in the socket runout is under 1 thou throughout. Hardest part of the measurement was landing a nice surface finish to measure the runout instead of surface bounce.

So yes, setting it by rise/run instead of copying was a definite win.

So now to shorten the nose and make the 5C features.

I skimmed the taper *without* tail support, and that got rid of the slight barrelling I'd detected.

This second time I also left much more nose on to facilitate measuring runout.

Dropped the new taper in, didn't bother with the 1/2-13 drawbar, and cut the nose to concentric. Popped it out, and re-inserted in the same orientation: runout of <1/10th at 1.5" away from the mouth of the spindle taper; even rotating it in the socket runout is under 1 thou throughout. Hardest part of the measurement was landing a nice surface finish to measure the runout instead of surface bounce.

So yes, setting it by rise/run instead of copying was a definite win.

So now to shorten the nose and make the 5C features.

I skimmed the taper *without* tail support, and that got rid of the slight barrelling I'd detected.

I often find that skimming works well without tailstock support even on longer stock. I have not tried that yet with carbide let alone sharp carbide.

I finally have a nice selection of sharp carbide so these tests will be done soon.