-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RF30 Basement Install

- Thread starter YYCHM

- Start date

Spent the day mounting the VFD and ESD switch on my mill bench today.

Out of the way but accessible. Took two trips to Rona and one to Lowes to find a suitable flush mount box to house the ESD switch. Man this 3 PH motor is quiet and smooth. When I was finished wiring everything up I gave the motor a test run and thought hmmmm some thing is wrong here it's not running, but it was.

Tomorrow I need to dig out all the crap that's under the bench so that I can route the power cords. Not Fun.

Out of the way but accessible. Took two trips to Rona and one to Lowes to find a suitable flush mount box to house the ESD switch. Man this 3 PH motor is quiet and smooth. When I was finished wiring everything up I gave the motor a test run and thought hmmmm some thing is wrong here it's not running, but it was.

Tomorrow I need to dig out all the crap that's under the bench so that I can route the power cords. Not Fun.

Looks good Craig. Wish I would have noticed that VFD when it was that super sale. Keep us updated on how it works.

Do you need to be able to run in reverse? This one doesn't support that as far as I can tell so far.

This one may go up for sale if my AliExpress VFD ever makes it out of mainland China. Ordered Oct 15 and still stuck in China.

Last edited:

RobinHood

Ultra Member

This one doesn't support that as far as I can tell so far.

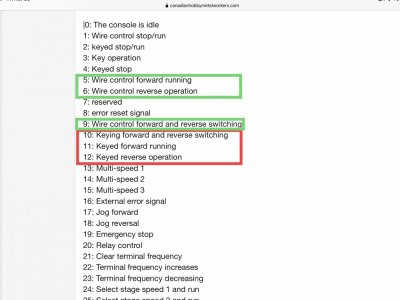

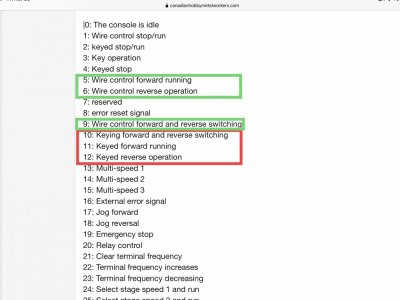

did your translated manual not say there was jog FWD and jog REV? If that is the case, then I don’t see why it would not give you FWD and REV.

from the lates post in the your “translation” thread items 9, 10, 11, and 12 seem to be the lugs where you select direction of rotation. First, you probably have to set the internal parameters to look at those inputs. Then, depending on the polarity of these inputs, the motor will run FWD or in REV.

My TECOs are exactly like that: enable the external inputs and then I set the direction with the original FWD/REV switch on the mill.

did your translated manual not say there was jog FWD and jog REV? If that is the case, then I don’t see why it would not give you FWD and REV.

from the lates post in the your “translation” thread items 9, 10, 11, and 12 seem to be the lugs where you select direction of rotation. First, you probably have to set the internal parameters to look at those inputs. Then, depending on the polarity of these inputs, the motor will run FWD or in REV.

My TECOs are exactly like that: enable the external inputs and then I set the direction with the original FWD/REV switch on the mill.

I've tried setting the F0.21-F0.25 parameters to no avail. There is no reverse jog option that I can find. You can set the jog frequency, jog acceleration and jog deceleration times and that's it. The jog is weird (or so I think). When you hold down the MF-K key it runs up to the jog freq and when you release the key it stops.

RobinHood

Ultra Member

Is there a little terminal strip where one can connect external control wires? It would be screw terminal that would accept maybe AWG 24 or smaller wires only.

From your translation, the ”Keyed/Keying” parameters could refer to the bottons on the key pad. The “wire“ reference could mean the external wires connected to the secondary terminal strip. Once enabled, the direction is controlled by the +12V DC (or whatever yours needs) inputs to those connections.

From your translation, the ”Keyed/Keying” parameters could refer to the bottons on the key pad. The “wire“ reference could mean the external wires connected to the secondary terminal strip. Once enabled, the direction is controlled by the +12V DC (or whatever yours needs) inputs to those connections.

That will be your controls. Once you close common with one of the x connections it should do what you have programmed. So like x1 to common is fwd and x2 to common is reverse. Etc.

ok..... nothing is labeled COM and there is no X6. So what is COM? Is it GND?

Last edited:

Phew.... long day.... finally got the 3PH motor mounted and running.

Started out by pulling all this junk out from under the bench. The plus side of that exercise is that I purged some stuff that hasn't seen the light of day in 15 years.

Next up was routing the cords and anchoring them. NOT FUN laying on your back on the raised shelf trying to set screws into something that's 4" from you nose.

Then came dismounting this 45 lb beast. Had to pull all of the top end. Idler assembly, motor pulley, spindle pulley, and belt cover etc.

Finally mounted the 35 lb 3 PH motor. First go I discovered that the belt cover interfered with the motor, so I had to dismount the motor and lower it on the mounting plate a 1/4". But finally she's up and running.

I'm impressed with how quite and smooth this thing runs.

I'm belted for 770 RPM and 60 HZ on the VFD gives me 790 RPM.

80 HZ is yielding 1055 RPM and 30 HZ is turning around 400 RPM.

So one belt up and two down without changing anything but the VFD HZ. As to the torque being usable in those ranges is still to be seen.

I'm going to feel this all tomorrow I'm sure.

Craig

Started out by pulling all this junk out from under the bench. The plus side of that exercise is that I purged some stuff that hasn't seen the light of day in 15 years.

Next up was routing the cords and anchoring them. NOT FUN laying on your back on the raised shelf trying to set screws into something that's 4" from you nose.

Then came dismounting this 45 lb beast. Had to pull all of the top end. Idler assembly, motor pulley, spindle pulley, and belt cover etc.

Finally mounted the 35 lb 3 PH motor. First go I discovered that the belt cover interfered with the motor, so I had to dismount the motor and lower it on the mounting plate a 1/4". But finally she's up and running.

I'm impressed with how quite and smooth this thing runs.

I'm belted for 770 RPM and 60 HZ on the VFD gives me 790 RPM.

80 HZ is yielding 1055 RPM and 30 HZ is turning around 400 RPM.

So one belt up and two down without changing anything but the VFD HZ. As to the torque being usable in those ranges is still to be seen.

I'm going to feel this all tomorrow I'm sure.

Craig

Last edited:

That will be your controls. Once you close common with one of the x connections it should do what you have programmed. So like x1 to common is fwd and x2 to common is reverse. Etc.

So I wired X1 to GND (COM?) and programmed it to be keyed reverse operation. No effect?

What your eluding to here doesn't make sense to me. There are 5 X terminals. If all 5 are programed differently and all 5 are wired to COM which one takes precedence?

You would need to wire in a switch to each of the 5 inputs so they could be connected to common one at a time to perform different functions.

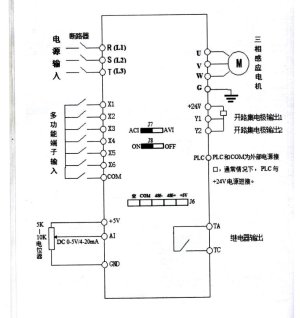

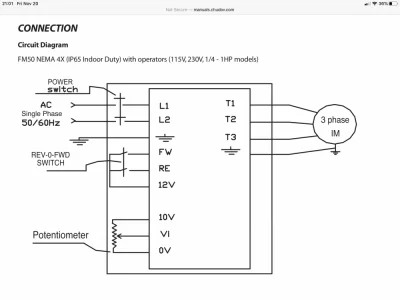

This is an example from my Huanyang vfd manual. In this example you can see that if the common terminal is connected to the top terminal it would give a forward rotation request to the vfd. The function of each of the input terminals is programmable. Your really need an English manual. Maybe it is similar to my Huanyang. I have the manual stored on Google Drive. PM me your email address and I send you a link to it.

This is an example from my Huanyang vfd manual. In this example you can see that if the common terminal is connected to the top terminal it would give a forward rotation request to the vfd. The function of each of the input terminals is programmable. Your really need an English manual. Maybe it is similar to my Huanyang. I have the manual stored on Google Drive. PM me your email address and I send you a link to it.

This link should get you to the Huanyang vfd manual.

https://drive.google.com/file/d/1mv7jXqR01P-Jrg7lA9S639xc_pUHHSQ8/view?usp=drivesdk

https://drive.google.com/file/d/1mv7jXqR01P-Jrg7lA9S639xc_pUHHSQ8/view?usp=drivesdk

This link should get you to the Huanyang vfd manual.

https://drive.google.com/file/d/1mv7jXqR01P-Jrg7lA9S639xc_pUHHSQ8/view?usp=drivesdk

Link requires you to login.

RobinHood

Ultra Member

There two modes of operation:

1) everything is controlled from the attached keypad;

2) some parameters are controlled from external inputs

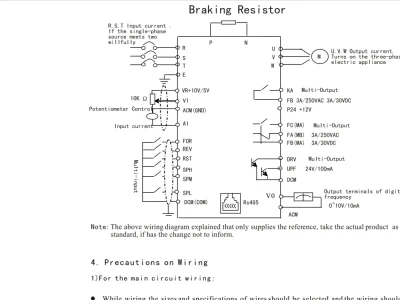

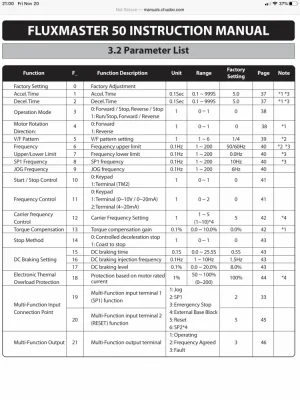

the VFD needs to know which mode of operation it is in (default is most likely 1)). This is where the Function programming parameters are set. Here is my Teco FM50

You can see under F10 you have a choice to set it to 0: Keypad or 1:Terminal. Same with Frequency Control (F11) - 0: Keypad, 1: Terminal (0~10V), 2: Terminal (4-20mA). It also shows the factory default for each of the function setting. Your VFD will be set up the same. You just need to tell it from where it gets the inputs (keypad or external) by setting the functions to the correct value.

Your main problem is that you don’t have an English manual. So you will have to step through all the functions and see which ones make sense. You do have the listing of what is where, so that should help you.

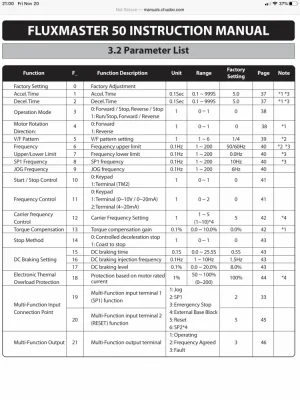

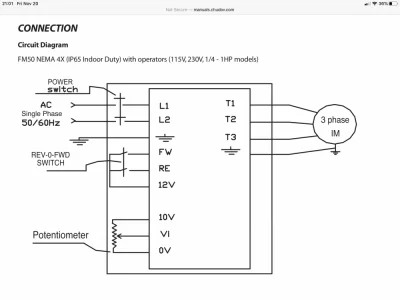

here Is the FM50 connection diagram. I know, not yours, but similar.

NOTE: I may be wrong in my previous post where I said that COM = GND. It could be, but not necessarily.

Just re-read my TECO FM50 manual and they use the term COM to represent 12V DC that is COMMON to multiple other circuit inputs.

I would check with a multi meter first. It may not be GND in your VFD!

1) everything is controlled from the attached keypad;

2) some parameters are controlled from external inputs

the VFD needs to know which mode of operation it is in (default is most likely 1)). This is where the Function programming parameters are set. Here is my Teco FM50

You can see under F10 you have a choice to set it to 0: Keypad or 1:Terminal. Same with Frequency Control (F11) - 0: Keypad, 1: Terminal (0~10V), 2: Terminal (4-20mA). It also shows the factory default for each of the function setting. Your VFD will be set up the same. You just need to tell it from where it gets the inputs (keypad or external) by setting the functions to the correct value.

Your main problem is that you don’t have an English manual. So you will have to step through all the functions and see which ones make sense. You do have the listing of what is where, so that should help you.

here Is the FM50 connection diagram. I know, not yours, but similar.

NOTE: I may be wrong in my previous post where I said that COM = GND. It could be, but not necessarily.

Just re-read my TECO FM50 manual and they use the term COM to represent 12V DC that is COMMON to multiple other circuit inputs.

I would check with a multi meter first. It may not be GND in your VFD!

If you Google "Huanyang vfd manual" you will get links to the same manual I have