-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RF30 Basement Install

- Thread starter YYCHM

- Start date

@kevin.decelles - I have heard that ASA is strong enough to make the pulley ind 3DP... food for thought?

Interesting..... I don't have any ASA, but I have some ABS that I'd be interested to try.

😳Ooooops….. not exactly what I intended.

I managed to take the shaft down to 0.858" on the first pass so now it's 0.0075" undersize. I thought I had just touched the tool to the shaft for the first pass not intending to take anything significant off?????

I any event I don't think it's a write off. There is a little bit of wiggle but not much. That pulley wiggles a little on the 1 ph motor as well.

Making the key is going to be fun.... I need the pulley on the mill to make the key yet I need the pulley off the mill to check the fit🙁

I managed to take the shaft down to 0.858" on the first pass so now it's 0.0075" undersize. I thought I had just touched the tool to the shaft for the first pass not intending to take anything significant off?????

I any event I don't think it's a write off. There is a little bit of wiggle but not much. That pulley wiggles a little on the 1 ph motor as well.

Making the key is going to be fun.... I need the pulley on the mill to make the key yet I need the pulley off the mill to check the fit🙁

I need the pulley on the mill to make the key yet I need the pulley off the mill to check the fit🙁

This my friend, made me laugh. Thank-you.

You get to use your drive plate and custom center, that’s a win!

Were you using a carbide or HSS tool? It’s hard to take a few thou with carbide.

I used a HSS tool due to the interrupted cut from the key way. Finish was excellent, just removed a little more material than I intended.

Is the ESD the primary method for stopping the mill?

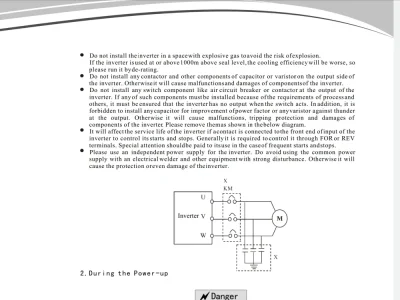

No, I'll use the VFD stop button for that. The ESD is the panic button and I though I would use it to power down the VFD when not in use however I question using it on the 1 phase side now since the VFD stays active for quite some time when it's unplugged (for more than a few seconds). Must have a large capacitor in it.

I think then it makes sense to put on the three phase side. Which leg of the three is better answered by an expert.No, I'll use the VFD stop button for that. The ESD is the panic button and I though I would use it to power down the VFD when not in use however I question using it on the 1 phase side now since the VFD stays active for quite some time when it's unplugged (for more than a few seconds). Must have a large capacitor in it.

I think then it makes sense to put on the three phase side. Which leg of the three is better answered by an expert.

The ESD switch will kill all three legs at once.

turner

Active Member

Why is it hard to take a few thou with carbide? I thought it was just me?You get to use your drive plate and custom center, that’s a win!

Were you using a carbide or HSS tool? It’s hard to take a few thou with carbide.

It's hard because the nose radius determines the DoC.Why is it hard to take a few thou with carbide? I thought it was just me?

Generally the nose radius is the minimum DoC.

Johnwa

Ultra Member

Carbide tends to be ”dull” compared to a sharp HSS tool. It can be sharpened but the the edge is very fragile. I can dial in and take of 10 to 15 thou and it will be as accurate as I can measure. If I try a couple of thou then it just rubs until I advance the tool enough that it starts to cut more than I want.Why is it hard to take a few thou with carbide? I thought it was just me?

The manual also says to make all wiring connections before powering up the VFD. I think they are mostly concerned with safety, I don't know if any harm would result from having no load attached.

Craig do NOT disconnect the motor from the VFD at any time! Your VFD can be ruined by the surges it will cause.

Your ESD switch, if you wire it on the primary side, will kill the power, but allow the motor to wind down freewheeling. If that's what you want, then your question is answered. On my TECO, there is provision for an orderly shutdown via an external switch, which would be how I'd wire it.

Your ESD switch, if you wire it on the primary side, will kill the power, but allow the motor to wind down freewheeling. If that's what you want, then your question is answered. On my TECO, there is provision for an orderly shutdown via an external switch, which would be how I'd wire it.

I have an ESD wired to mine, but it is a low-voltage input to the VFD which signals the stopping of the motor (VFD stays powered). The VFD allowed for the configuration of a bunch of inputs and this was one of the options. Similar to how you can choose a forward/reverse/jog etc. When you invoke the ESD -- it outputs AES on the VFD so you know it is engaged.

In addition, I use a 220V contactor on the 1ph input side that is my master off (I don't leave it running when I'm not using it.

In addition, I use a 220V contactor on the 1ph input side that is my master off (I don't leave it running when I'm not using it.