You can tell pretty quickly by looking at the feed rod, it should be ratcheting back while the ram is moving forward.....

I had a good look at how it all works. It's not obvious at all and some of it isn't even mentioned at all. It will take me a while to sort through everything.

The good news is that your quick check works out ok for the cut I was taking. Well, I say good news but I suppose bad news would have been better in terms of fixing the issues. Bottom line is that my feed happens, during the return stroke, not during the power stroke.

It seems rather obvious to me that rigidity in this little shaper isn't going to be stellar. There may be lots of things like this that need to be compensated for or just outright accepted and lived with.

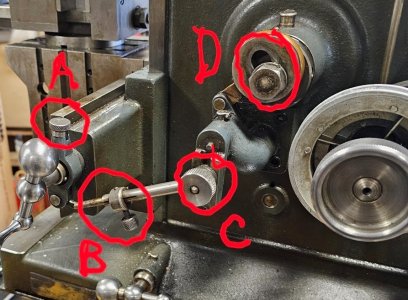

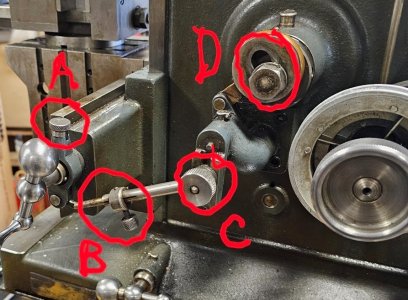

One thing I noticed right away when I was investigating your suggestions. There seems to be four ways to adjust the feed rate. A, B, C, & D in the photo below.

A has 4 positions R, L, and 2 neutral. The R position moves the table Right, and the L position moves it Left. The neutral positions allow the user to move the table manually. Moving it manually in L or R, does not appear to be healthy.

The B adjustment just seems to clock the feed arm relative to the feed drive. I suppose that there are preferred relative locations that maximize or minimize the relative translation. It works as is and seems to be pretty close to 1 to 1 so I've left it alone as is.

The C & D adjustments are quite interrelated. Both will increase or decrease the feed stroke which increases or decreases the feed rate. C is a plain linear adjustment that even has numerical markings on it.

D is the most interesting. There are no graduations and no directional indicators. However, moving the eccentric to one extreme or the other changes the timing of the feed to coincide with the direction of the Ram - feed during power stroke or feed during retract (what you referred to in your earlier note). There are no markings to show which is which. I suspect you should normally choose which one you want at the same time as you adjust the length of the Ram stroke. However, you can also set the eccentric to intermediate positions ranging from full eccentricity to zero eccentricity to full opposite eccentricity. I gather the choice is best used simply to fine tune adjustment C.

Comments? Did I miss anything or mess anything up?