Emery

Member

Well..... before jumping the gun. What speeds did you get with the pulleys swapped? $80 is a lot for something you have to butcher to make work.

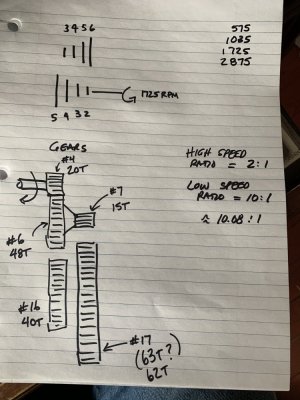

I did some calculations and if the larger pulley is put on the motor side it will up my RPM’s even more.

I would prefer to buy a perfect replacement but that does not seem to be an option and I’d like to have a little bit more range from my gearbox in the 300 - 400 RPM area