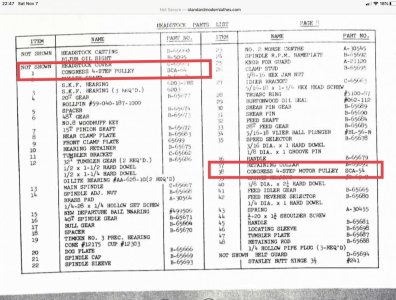

very interesting... The speeds are definitely accurate enough to seem correct. 50 RPM is in the correct spot and 1500 RPM is in the correct spot everything else seems “normal”.

can you guys pass along some measurements to make sure mine are not “custom farm”.

If they just took off the top and put it on the bottom and vice versa without flipping the orientation the RPMs shouldn’t change.

In what belt position do you get max rpm? Closest to the head stock or farthest from the head stock? Have you checked spindle RPM with a tachometer?

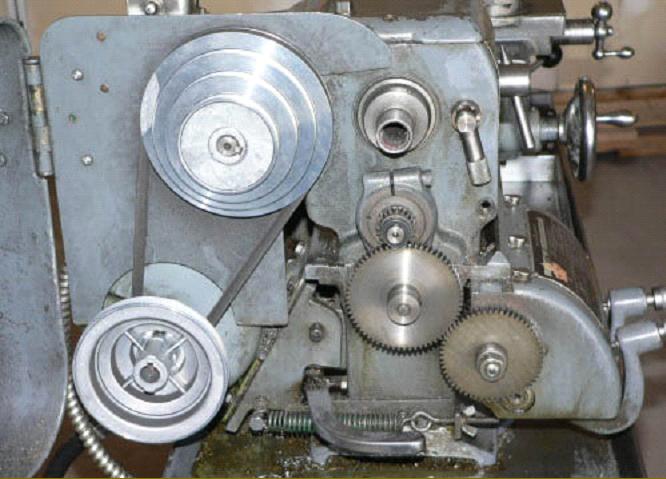

BTB - Your machine is cleaning up nicely....