deleted_user

Super User

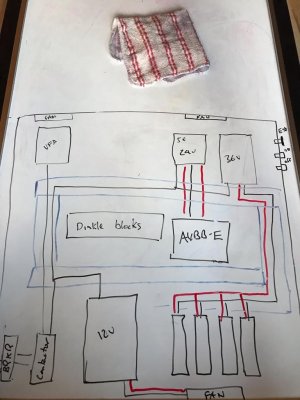

Dropped all the major components into the computer case today.

From top left:

VFD

12v power supply for control board

36v power supply for stepper drivers

(fan which will go above the power supplies)

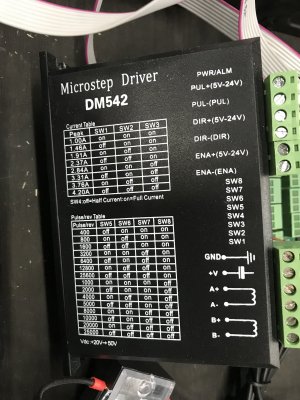

Four stepper drivers

Control board

I will mount another fan on the bottom of the enclosure to blow across the stepper drivers.

Waiting on wire raceway before I can start wiring in earnest.

View attachment 19961

what brand stepper drivers does the aliexpress store sell?

I think I'm going to start making small purchases locally when I see deals. I'm also going to go with DIN mounted power supplies and make mounted for the stepper drivers. I have a bunch of DIN terminal blocks already