Big step today. I submitted the order for all the parts.

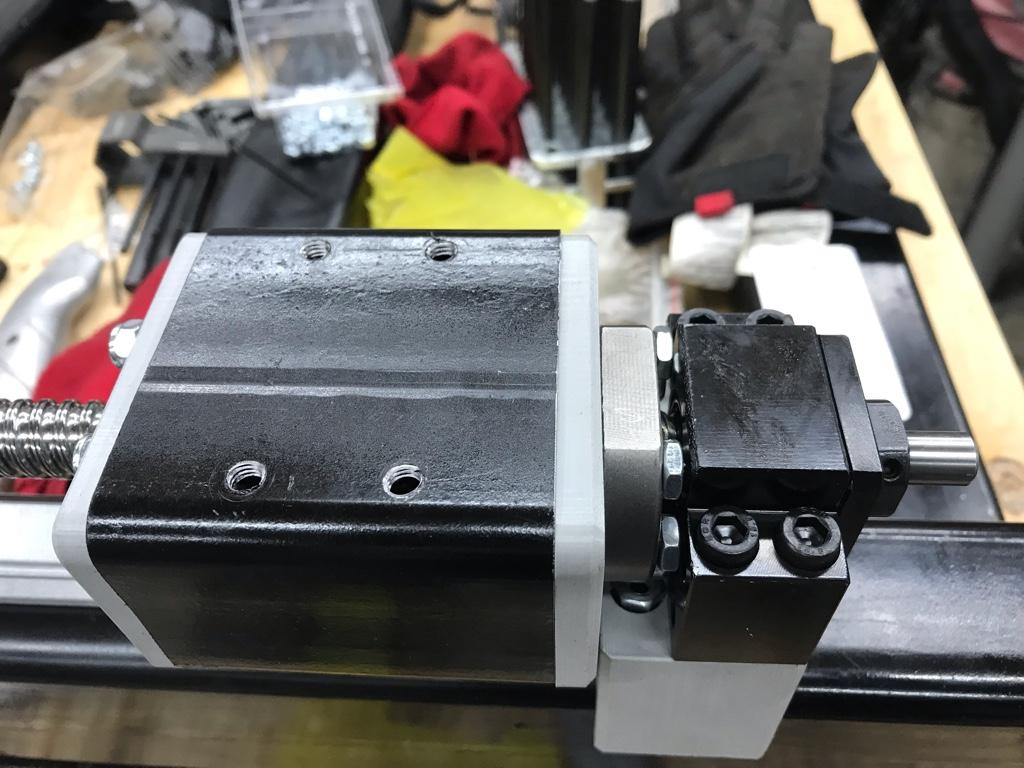

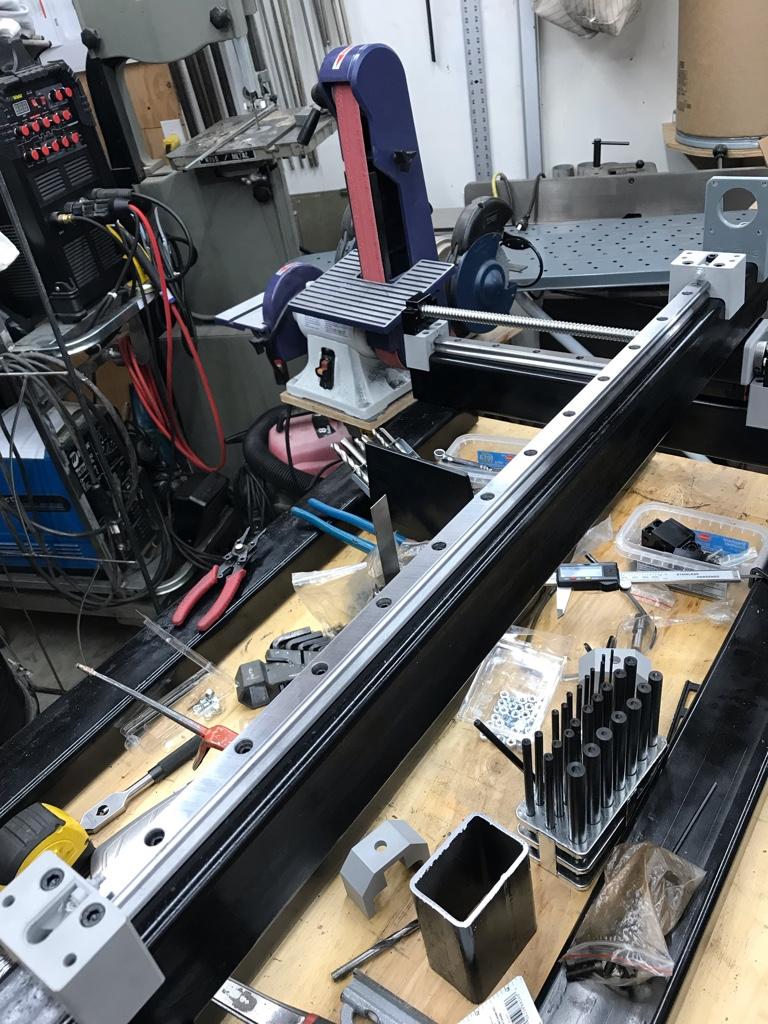

Linear rails

725mm HGR20 QTY (2)

425mm HGR20 QTY (2)

250mm HGR20 QTY (2)

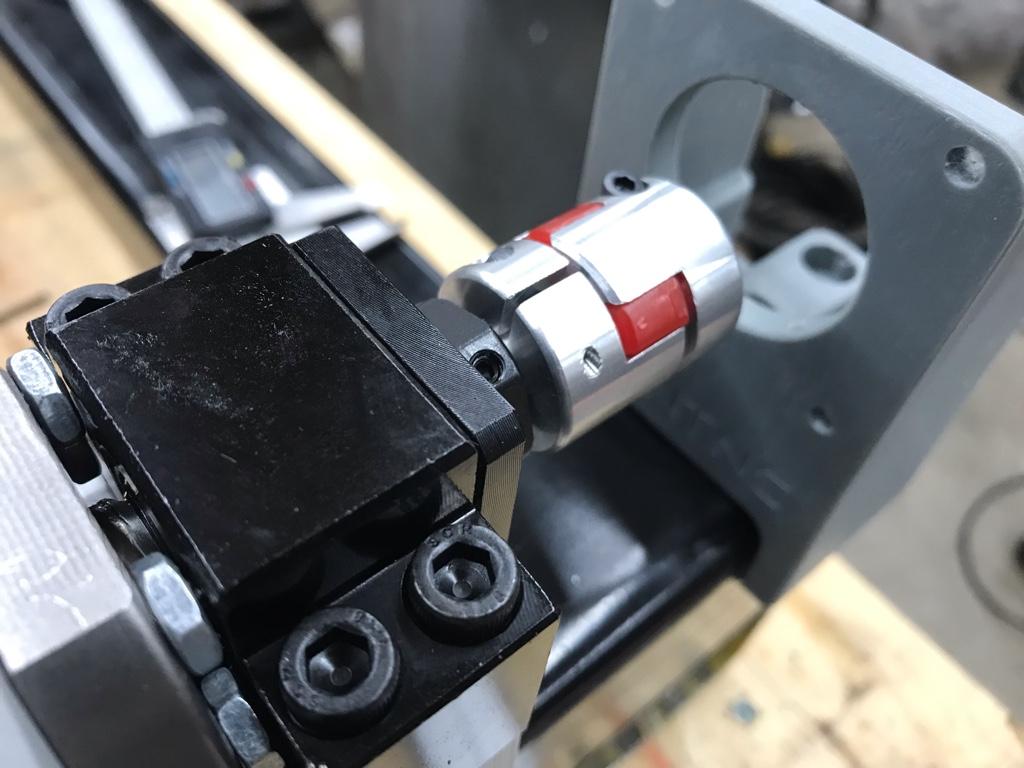

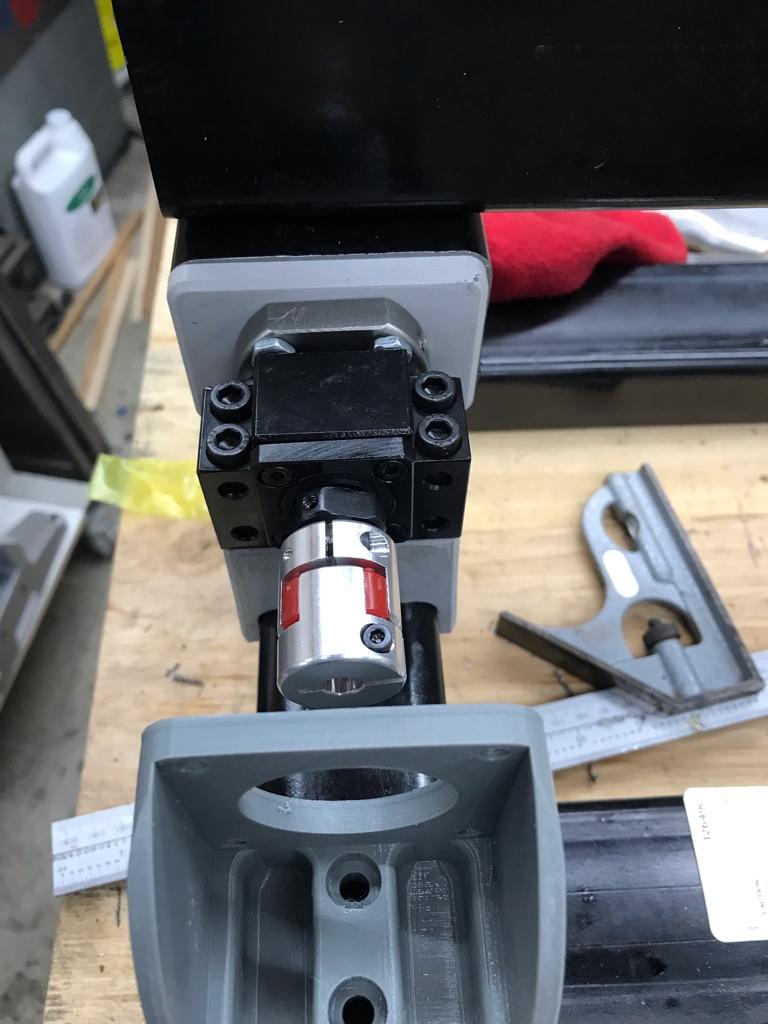

Ball screws

825mm 1610 Ball Screw QTY (1)

525mm 1610 Ball Screw QTY (2)

300mm 1204 Ball Screw QTY (1)

HGW20CC QTY (6)

@David_R8 Where did you order these supplies from? McMaster or elsewhere? Sorry if I missed it. You might have mentioned it somewhere. I wondered about making my Plasma cutter with ball screws and 1x2 tubing instead of the gear rack. Since you mentioned that this router build could do plasma too, I am wondering if building a more rigid frame for my first build could do both router and plasma. But knowing nothing about this stuff, perhaps building the plasma like yours is worth the lessons learned in the process. It sounds, from your posts, you are learning very quickly.

I don't know much about either so just pondering out loud.