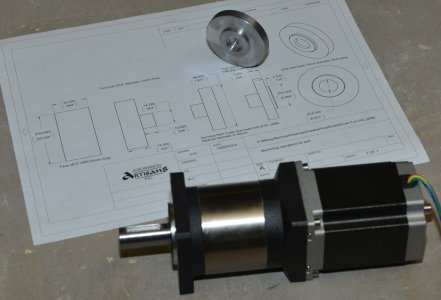

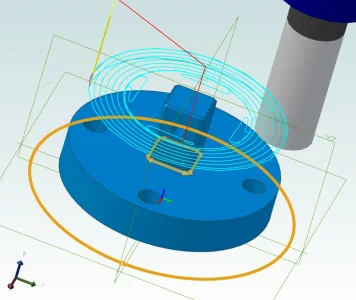

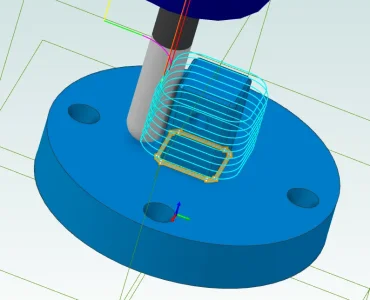

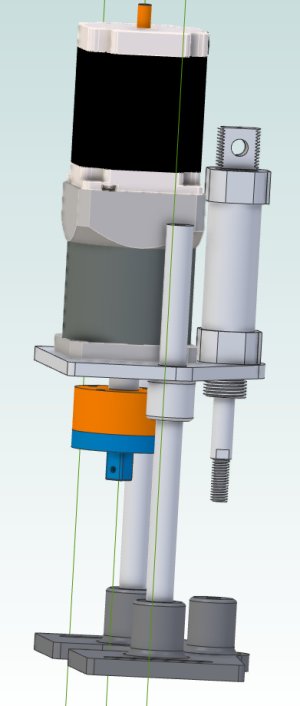

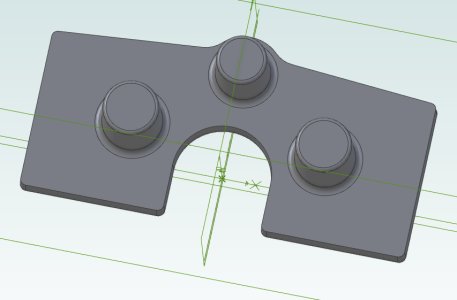

So time to make the two adapters for the stepper motor planetary drive so I can turn a socket.

Start with the raw materials. In this case 2" steel bar. Two pieces.

Dew point has risen in the shop by one degree since it's also pretty warm outside.

Start with the raw materials. In this case 2" steel bar. Two pieces.

Dew point has risen in the shop by one degree since it's also pretty warm outside.