-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

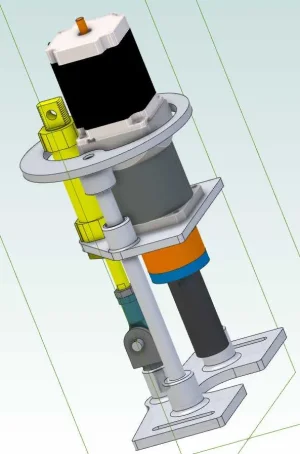

Micro-controller controlled Pneumatic Power Draw Bar

- Thread starter jcdammeyer

- Start date

140mower

Don

...... I doubt many of us can count that high....I'm surprised no one has asked why every one of my projects is #42.

Try this then....... I doubt many of us can count that high....

A=1, B=2, C=3,... Z=26. If you add together the numbers representing the letters MATH you get 42.

Try this then.

A=1, B=2, C=3,... Z=26. If you add together the numbers representing the letters MATH you get 42.

This was brought up before and I still don't get it. What significant about MATH = 42?

Math is the answer to life, the universe and everything. At least according to "The Hitchhiker's guide to the galaxy".This was brought up before and I still don't get it. What significant about MATH = 42?

And the question, apparently is "what is 6 x 9?" The implication, then, is that god has 13 fingers.Math is the answer to life, the universe and everything. At least according to "The Hitchhiker's guide to the galaxy".

I'm surprised no one has asked why every one of my projects is #42.

I noticed but just thought it was funny. Don't change. That's a joke that never gets old. I'll keep laughing.

Anyway back to the draw bar...

Using the Alibre CAD I can create the parts and make sure there isn't any interference.

Then take those parts, remove the holes, change a few dimensions and add taper so it will pull out of the sand for casting.

They are now 3D printed. Next step is sand off the rough parts of the tapered posts. Add filler and primer and make them smooth enough to pull.

Then cast. Each plate is only just a tad thicker than 1/4"

Using the Alibre CAD I can create the parts and make sure there isn't any interference.

Then take those parts, remove the holes, change a few dimensions and add taper so it will pull out of the sand for casting.

They are now 3D printed. Next step is sand off the rough parts of the tapered posts. Add filler and primer and make them smooth enough to pull.

Then cast. Each plate is only just a tad thicker than 1/4"

Attachments

Former Member

Guest

Throw yourself at the ground and miss.Math is the answer to life, the universe and everything. At least according to "The Hitchhiker's guide to the galaxy".

I do that all the time. Doesn't everyone??????Throw yourself at the ground and miss.

Found this video on a tool changer for a PCB drilling operation. It's an upside down version of what I'm trying to do and has other features that don't apply to a draw bar.

But overall the same idea that I'm pursuing now with the stepper motor and planetary drive for tightening/loosening. And like his my plan is to change the amount of current to the stepper motor to change the torque so there is more for loosening and less for tightening.

John

But overall the same idea that I'm pursuing now with the stepper motor and planetary drive for tightening/loosening. And like his my plan is to change the amount of current to the stepper motor to change the torque so there is more for loosening and less for tightening.

John

Yahoo. My tool height setter arrived. Not directly related to the drawbar project but for tool changing those few times where I need to use R8 instead of a TTS holder or if I put a different tool into a TTS holder and need to get the height of that into the LinuxCNC tool table.

Now to figure out where to wire it.

Now to figure out where to wire it.

Needless to say I almost dropped everything just so I could play with it. Sensitivity is good. The over travel N/C switch opens and could be put in series with the Z travel limit switch.

Here's it sitting on the mill table at the tool change position which is almost at the X and Y limit switches.

If I mount it there permanently I can see it will be constantly in the way. Going to have to figure out some sort of fast attach method.

Here's it sitting on the mill table at the tool change position which is almost at the X and Y limit switches.

If I mount it there permanently I can see it will be constantly in the way. Going to have to figure out some sort of fast attach method.