No matter what I do to the top of the draw bar the 12pt socket still can jam onto the draw bar head. The head is just too soft.

And I now see that the head was either welded or glued or threaded onto the draw bar shaft.

The metal is very soft so I tried heating it to orange/yellow with the torch and quenching in water. That didn't work. Still soft. I can pull down against the springs by hand (no air pressure attached) and just that action can jam the socket onto the head.

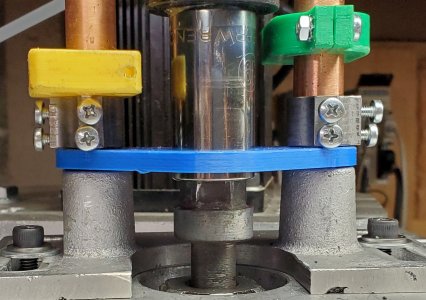

To prevent rounding the nut and random carving of the head I added a second hall sensor on the other post and magnet attached to the cylinder body to sense when the draw bar socket is down all the way. Tweaked the software to deal with that and if not all the way down then go back up and blip wrench and try again. Problem there is now that the socket is sticking to the draw bar head it brings the unloaded draw bar up with it so that's not working. If the drawbar is attached to a collet then the socket can be pulled really hard. It was coming off but I've fixed the retainer so that works better.

Next step is to somehow attach a 12mm bolt from Home Depot (with the 19mm head) onto the draw bar. It's definitely harder than what's there. If that doesn't work I'll look at some oil or water hardening stock and make something really hard.

And I now see that the head was either welded or glued or threaded onto the draw bar shaft.

The metal is very soft so I tried heating it to orange/yellow with the torch and quenching in water. That didn't work. Still soft. I can pull down against the springs by hand (no air pressure attached) and just that action can jam the socket onto the head.

To prevent rounding the nut and random carving of the head I added a second hall sensor on the other post and magnet attached to the cylinder body to sense when the draw bar socket is down all the way. Tweaked the software to deal with that and if not all the way down then go back up and blip wrench and try again. Problem there is now that the socket is sticking to the draw bar head it brings the unloaded draw bar up with it so that's not working. If the drawbar is attached to a collet then the socket can be pulled really hard. It was coming off but I've fixed the retainer so that works better.

Next step is to somehow attach a 12mm bolt from Home Depot (with the 19mm head) onto the draw bar. It's definitely harder than what's there. If that doesn't work I'll look at some oil or water hardening stock and make something really hard.