Not a dumb question at all.

The bushings in the impact wrench are designed to be oiled with the supplied air. As such spinning them without that oil might damage them. Then there's also the tangs inside the wrench that under light load may well click back and forth making noise.

A clutch such as this:

DC Clutch might well work but the size is prohibitive without a total frame redesign.

Eliminating the socket would then also require a redesign of the end of the draw bar. At this point, aside from the redesign, there still needs to be a way to manually remove it if something fails with it tightly in place.

Again the big issue is for TTS tooling I want no more than 2 turns in the CCW and probably 3 seconds in the CW so the impact wrench can reach 15 to 25 ft-lbs of torque. The other postings with various rotary power draw bar subjects all use R8 tooling and spin CCW until the R8 drops out. Watch the videos closely of the manually engaged versions and if the socket doesn't go down all the way there's a slight twist of the handle to blip the air wrench just enough to move it slightly without excess pressure on the nut. And in one thread the need for the 12 point socket was emphasized. So when a human is involved the slight behavior changes are handled without thinking.

But I also want the ability to swap R8 tooling so mine is a dual operation draw bar. So far I haven't seen any other threads or you tube videos that deal with that.

If I were to start over I'd look at a 300 oz-in stepper motor and probably a 20:1 planetary drive. A few days ago the drives on Aliexpress were all in the $39 range. Yesterday they were all in the $70 range. In either case, a change to a fully electric version still runs up to $200 with drive etc. And some major redesign.

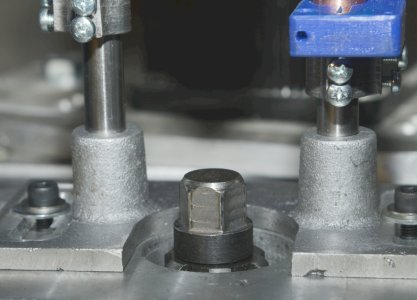

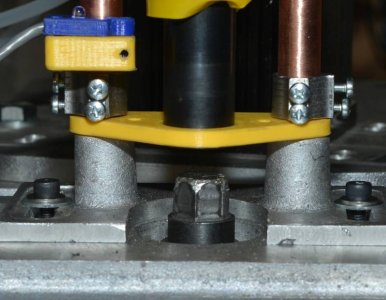

I've found one of the bigger issues is when the socket doesn't descend all the way and it starts to spin the magnet isn't lined up with the hall sensor so it defaults to timed turning which polishes or marks up the top of the draw bar even more. I think a switch to detect fully down before turning might be the solution. Then if it isn't down I can move it up, blip it to turn a tad, and try again. With a 12 point socket likely it will drop into place quite quickly and then a 2 turn spin to undo it leaves the R8 in place and the TTS drops out.