Jswain

Joe

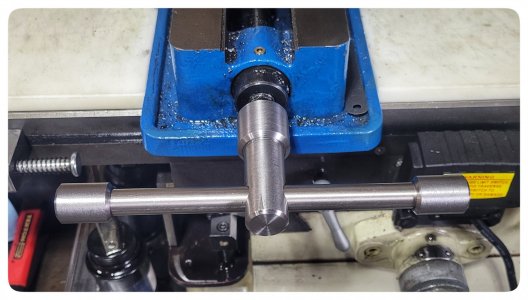

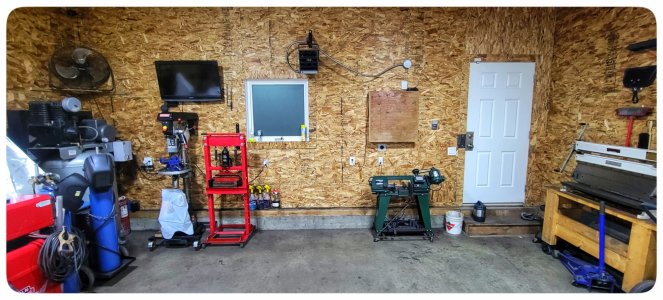

Drug this home last night with me, the stand I'm assuming used to be a toolbox with some drawers/supports removed. Was a flimsy piece of crap and too high. Handles would hit the shelves/cupboards no matter where I placed it so I actually got buyers remorse for a minute.

Then I woke up today and took it back off the stand(pain), flipped it upside down and chopped 4" off the legs, flipped the wood on the roller base. Ok much better

Took some 2x4's and built some braces to go back inside the unit. Then used the sheet metal I cut off to build some covers/skirts and ok now the buyers remorse is gone.

Then I woke up today and took it back off the stand(pain), flipped it upside down and chopped 4" off the legs, flipped the wood on the roller base. Ok much better

Took some 2x4's and built some braces to go back inside the unit. Then used the sheet metal I cut off to build some covers/skirts and ok now the buyers remorse is gone.

Attachments

-

1000006471-01.jpeg398.3 KB · Views: 33

1000006471-01.jpeg398.3 KB · Views: 33 -

1000006474-01.jpeg433.3 KB · Views: 30

1000006474-01.jpeg433.3 KB · Views: 30 -

1000006475-01.jpeg385.7 KB · Views: 26

1000006475-01.jpeg385.7 KB · Views: 26 -

1000006476-01.jpeg451.3 KB · Views: 23

1000006476-01.jpeg451.3 KB · Views: 23 -

1000006477-01.jpeg470.6 KB · Views: 25

1000006477-01.jpeg470.6 KB · Views: 25 -

1000006479-01.jpeg383.6 KB · Views: 30

1000006479-01.jpeg383.6 KB · Views: 30 -

1000006480-01.jpeg341.8 KB · Views: 28

1000006480-01.jpeg341.8 KB · Views: 28 -

1000006489-01.jpeg680 KB · Views: 33

1000006489-01.jpeg680 KB · Views: 33