The step file shows two different parts. I can suppress the lathe bed.

And then create a drawing of it.

Yes, that's exactly what I did too.

The step file shows two different parts. I can suppress the lathe bed.

And then create a drawing of it.

I rarely use sketches. start with clay, add, subtract, split offset... etc... then KILL the history .. (kill is my favorite button.. kills the tree)

That sounds more like Catia. You don't start with 2D and morph that into 3D. You start with 3D solids that you shape as appropriate.

Does Fusion have clay and kill functions?

So what exactly is the problem?

If I save the assembly file and then reopen it I can then edit the individual parts as ad_prt files. For example I put a 0.25" hole in the top part. The 2D drawing was still open so I had to explicitly tell it to 'Reproject' the views.Yes, that's exactly what I did too.

That sounds more like Catia. You don't start with 2D and morph that into 3D. You start with 3D solids that you shape as appropriate.

I don't agree with this workflow at all, at least in any CAD environment. Is like burning your blueprints after a part has been manufactured... to accomplish what?.... save valuable real estate within your filing cabinet? What inevitably happens is a minor design change is subsequently required, or a need for a very similar part variant. Or an error is discovered. So with no history available, starting all over again from scratch is somehow more efficient? The memory occupied in the sketches & dimensions is trivial. If you have named & documented your tree elements like you should be doing, you or anyone else should be able to walk through the development steps of that part & see what's going on. Why would you kill that valuable information?

Another red herring is this notion of 'sculpting' from a primitive solid down towards a resultant part vs. 'growing' or 'building up' a part from sketches & their specific 3D operations. One is not better than the other, they are opposite sides of the same coin. Sometimes removing material is the more logical workflow & sometimes its not. The objective is to develop the part in the way that makes the most sense. Some of this thinking stems from earlier 3D programs, or different 3D apps liked mesh modelers (a completely different animal to most conventional 3D modelers). Some of it is self inflicted as people try to relate to programs or explain workflows in practical terms. Some of it possibly stems from CNC machines which have (limited) CAD-like capabilities, but again is different than modelling a part in 3D CAD & importing to a CNC.

Here is the workflow in molds for example.Sorry for sidetrack to what is a Fusion post. I've never seen CATIA but always assumed it was $$ industrial strength 3D software, but more or less workflow aligned to alternate parametric apps like Inventor, SolidWorks etc. which are heavily sketch driven. Google is a dangerous thing, but it seems to contradict what you've stated.

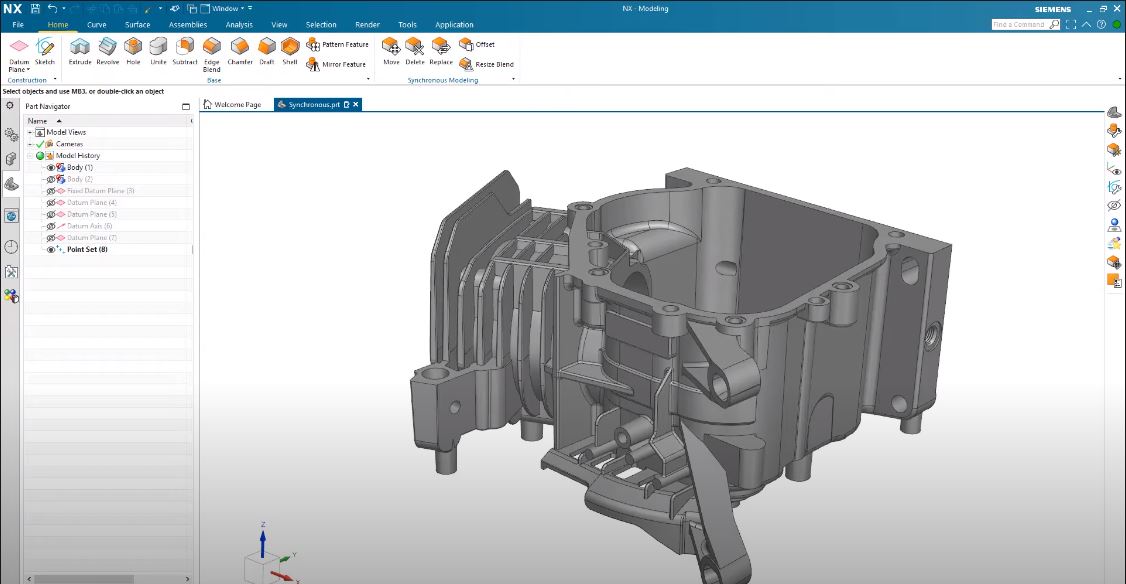

View attachment 41920

Sorry for sidetrack to what is a Fusion post. I've never seen CATIA but always assumed it was $$ industrial strength 3D software, but more or less workflow aligned to alternate parametric apps like Inventor, SolidWorks etc. which are heavily sketch driven. Google is a dangerous thing, but it seems to contradict what you've stated.

View attachment 41920

And I can visualize instances where the CAD designer specifically may not want their secret sauce conveyed to 3rd party manufacturing by sending the CAD file. But I suspect for home brew hobby machinists, Mr. CAD & Mr. CAM & Mr. CNC is usually the same guy. Which is why I said deleting history is counterproductive. Actually (and I don't know much about the CAM side) but when I 'save as' .step or .iges or whatever from within CAD it produces a new file specifically for CAM, there is no embedded history that I'm aware of anyways. The original CAD file is none the wiser. Am I missing something?

I modified your concept. Note the cap screws on top for easy locking. Just need side screw for adjustability.I whipped this off my 3D cellulosic duplicator.

View attachment 41924

The small block is the sliding lock.

View attachment 41925

Fits perfect as drawn.

Some more functional requirements to add, and also some cosmetic features and bevels but so far so good.

I like that. the bottom part having the little step insures the pressure is direct and prevents it from rocking... Thankyou for the input...Or if you don't want to hunt for the hex key, sprung handle thingamabob. These are carriage stops, but same concept

The time I “kill the design history” is when I’ve got a complicated assembly and I’ve exceeded the ability of my computer to manage it. Then I’ll start exporting major assemblies as an STL file and import that back in. I still have the original parametric model of course.I don't agree with this workflow at all, at least in any CAD environment. Is like burning your blueprints after a part has been manufactured...

There are some recessed magnets holding it on (covered with 1/32 ply to make it easier to remove the chips that get on the magnets)

It does have these capabilities.Does Fusion have clay and kill functions?

If you’ve come across something where you think “this would be so easy to do with a file”, then you probably need to use the Surface workspace…