Brian H

Super User

@Jswain- yes, and yes it translates to the workpiece

@historicalarms - I am not sure how I would check for consistent gear mesh.

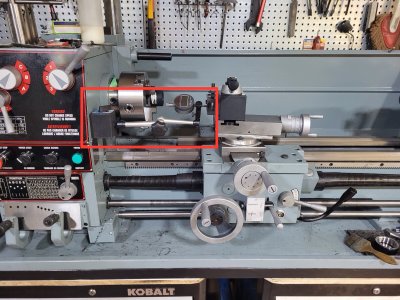

@Bandit ,@PeterT, @RobinHood - I started with the clamshell engaged, turned the chuck to remove backlash, set up the dial indicator (on the tailstock side of the carriage, then turned the chuck the number of threads chosen looking for a 1" movement.

I have a witness mark on the chuck and headstock for a reasonably accurate reference point. I did everything by hand without the lathe even powered up

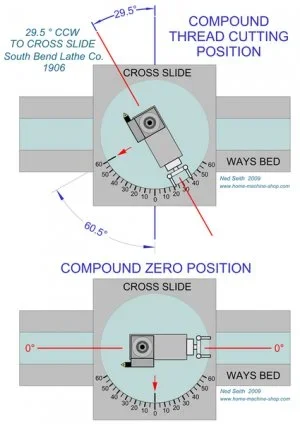

@Janger -indicator is on a magnetic base. I actually am considering getting another one( one on each side of the carriage) to verify the movement. Having two indicators probably isn't a bad thing anyway. And yes, I confirmed headstock lever is on threading, not powerfeed and yes, half-nut lever is engaged on the apron

@historicalarms - I am not sure how I would check for consistent gear mesh.

@Bandit ,@PeterT, @RobinHood - I started with the clamshell engaged, turned the chuck to remove backlash, set up the dial indicator (on the tailstock side of the carriage, then turned the chuck the number of threads chosen looking for a 1" movement.

I have a witness mark on the chuck and headstock for a reasonably accurate reference point. I did everything by hand without the lathe even powered up

@Janger -indicator is on a magnetic base. I actually am considering getting another one( one on each side of the carriage) to verify the movement. Having two indicators probably isn't a bad thing anyway. And yes, I confirmed headstock lever is on threading, not powerfeed and yes, half-nut lever is engaged on the apron