@Brian H - I am paranoid of crashing while cutting metric threads because I couldn't disengage the half nut. I previously posted about a method I ran across a while back that allows you to disengage the half nut while cutting a metric thread. I have tried it and it works great.

Thread 'Metric Threading on an Imperial Lathe'

https://canadianhobbymetalworkers.com/threads/metric-threading-on-an-imperial-lathe.4616/

It should work on any imperial lathe that has the change gears required to cut metric threads.

Once you get your 1.5 pitch problem worked out, give it a whirl. I think you will love it!

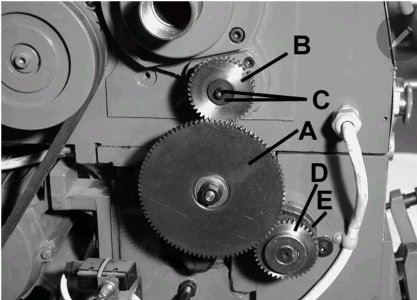

Regarding your pitch problem, it looks to me like your lathe is just not syncing the 127 tooth gear properly.

The 127 gear is usually stacked in front of or behind your gear A, and you have to flip either the bottom or top gear to engage it instead of the other gear.

Your photo looks to me like you do have the 127 gear. It's either the front one or the rear one marked A in the photo you provided earlier.

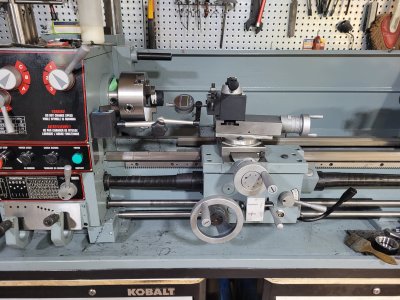

View attachment 46099

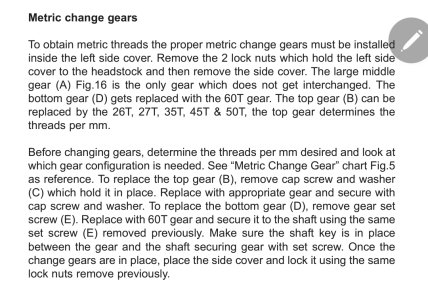

I found your manual and made copy of the relevant section. Frankly, the description is VERY POOR. It describes selecting the right threading gear but makes no mention of how to properly engage the 127 gear.

Usually on this type of lathe, you "invert" or "flip" gear B in my markup or gear E in the king manual to select which of the two stacked gears of A gets used.

Here are screen shots of the King Manual. Maybe yours is different.

View attachment 46103

View attachment 46104