Hey

@Brian H, I confess I have some trouble accepting the situation you find yourself in.

I went back and reviewed the whole thread.

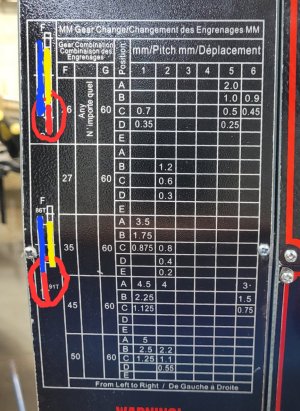

In post 13 you provided a photo of your gear chart. I have marked it up.

View attachment 48187

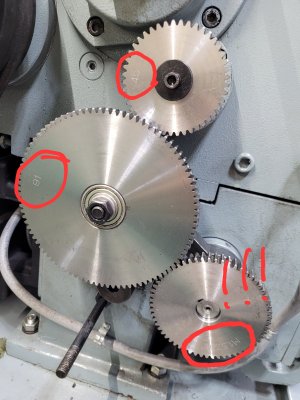

According to this chart, it clearly shows that the bottom gear is reversed for a 1.5 pitch metric thread and also elsewhere in those photos IT LOOKS LIKE that gear either has a bushing under it or has an attached bushing.

The bottom gear is gear G. Can you please remove it and see if it is reversable? Maybe take some photos of the gear? It might explain everything.

Try to think about this whole matter as if someone (either before or after the sale) broke something or lost something and repaired it by substituting stuff that doesn't belong.

Certainly, that chart suggests that your bottom gear G should be reversible.