-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Do you have a mill and what kind is it?

- Thread starter Susquatch

- Start date

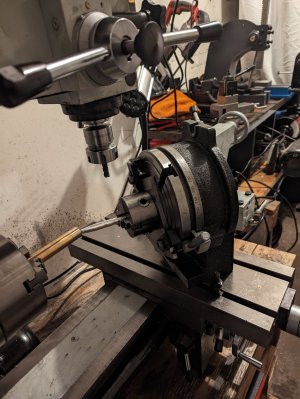

and here I have a setup for milling across stock that I can rotate on the vertical table. I just set this up for the camera, but the milling can be done perpendicular, longitudinally, or at an angle to the stock to produce different patterns

The versatility of that whole rig is amazing. My two buddies don't go anywhere near using their machines to that extent. Very impressive. Can't wait to show them.

Thank you

I also have the MD45. 🙂

FYI - I was at Modern Tool yesterday finalizing arrangements for our meetup. They have a MD45 in stock and it is one of the machines being demonstrated at the April 6 meetup in Newmarket.

They will also have a 11x26 lathe set up for us to try (it is behind the MD45 in the attached picture).

Meetup attendees will be allowed to operate (test drive) any machine being demoed. As well as the above mentioned machines will be a new Modern Tool 1440 lathe.

More meetup details TBA.

FYI - I was at Modern Tool yesterday finalizing arrangements for our meetup. They have a MD45 in stock and it is one of the machines being demonstrated at the April 6 meetup in Newmarket.

They will also have a 11x26 lathe set up for us to try (it is behind the MD45 in the attached picture).

Meetup attendees will be allowed to operate (test drive) any machine being demoed. As well as the above mentioned machines will be a new Modern Tool 1440 lathe.

More meetup details TBA.

ChazzC

Ultra Member

LMS 3990 Mini-Mill with a 2" Riser (and like the Mini-Lathe, a number of updates). When I win the lottery I'll upgrade to a PM (probably) Bench Mill.This thread is a poll to determine the range of mills that our members have. If the poll questions are not adequate, please provide additional comments below.

Martin w

Ultra Member

I have a John Deere, lol. I mean K&T 2HL vertical mill and a Giddings and Lewis horizontal boring mill. K&T has a 40 nmtb taper G&L has Morse #5 and Morse #4 on the high speed spindle, but it is set up with PDQ quick change tooling.

Yes I know I’m eccentric for having these in my barn. The boring mill is 21,500 pounds. Price was right so I grabbed it. It’s behind the old Ottawa Saw in the picture.

Martin

Yes I know I’m eccentric for having these in my barn. The boring mill is 21,500 pounds. Price was right so I grabbed it. It’s behind the old Ottawa Saw in the picture.

Martin

Martin w

Ultra Member

Bandit, the boring mill is in the middle. That’s what holds the concrete floor down.🙂Teeth are abit course for metal, "Martin w". That would be a bit noisy in the shop! Haven't seen one of them saws for a few years. What did you put on the other side of the shop to balance the boring mill?

Yeah the old Ottawa doesn’t do so well on steel,! People were strapping, hardy and rugged back in the day to use that.

Martin

Ironman

Ultra Member

And then they invented the chainsaw, much easier to fall trees with😛Yeah the old Ottawa doesn’t do so well on steel,! People were strapping, hardy and rugged back in the day to use that.

Martin

Kernel Sanders

Well-Known Member

No mill at the moment but using a small vertical slide on my small lathe. barely suitable 😉