I'm feeling a bit overwhelmed here. It's bad enough trying to understand

@PeterT s points and now I gotta understand what

@Degen is saying too! Then

@StevSmar adds another stinker to the mix....... SHEEESH!

@Degen - I took me ages to figure out that Peter is more interested in the geometry of measurements and what they "could" mean to the overall alignment process. Hence his "assume the bed is perfect". At the back of his points is the final objective of aligning the lathe. But first he wants to play with the cause and effect process so he can rely on the data to get the desired result. I respect that very much but I think it can be a bit confusing if you are just trying to align your lathe and don't care about the geometry involved in taking the measurements.

@PeterT - I think

@Degen is heading straight into the alignment process biased somewhat by his earlier stated preference for using a perfect test bar. Which many of us now think prolly only exists for a short while (if at all) and then expires! LOL! Regardless of whether or not we have a good test bar, I think ALL OF US agree that the bed must be "untwisted" (levelled) first! Otherwise we chase our tails eternally. I don't think

@Degen is particularly interested in what happens to hypothetical measurements along the way.

My observation is that both of you are correct within the limits of your respective assumptions. My apologies in advance if any of that comes across as criticism. It is not intended that way. It's only MY personal perception of the discussion. Please understand that that perception is complimentary, not critical.

Meanwhile though, that crazy lunatic

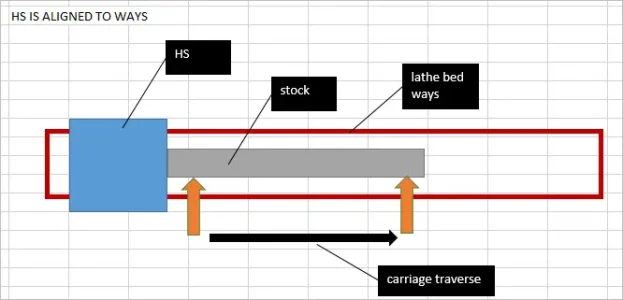

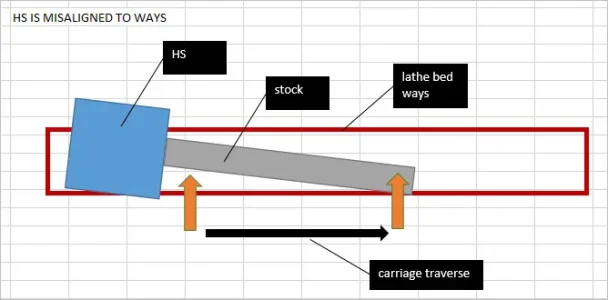

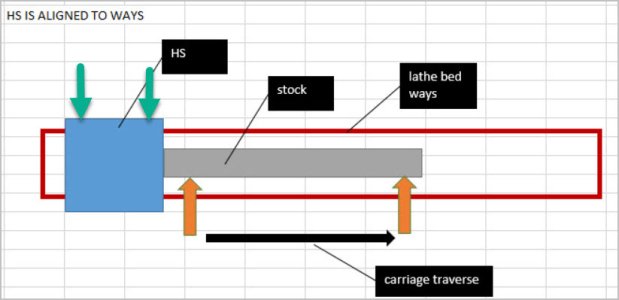

@Susquatch just wants to make a better tool to evaluate and potentially help correct head misalignment. That project of his assumes the bed has been corrected already.

Personally, I find all of the discussion very useful to me. On the other hand, other observers on the forum may be rolling their eyeballs at all of us!

Now for

@StevSmar ...... Are you crazy? Why in the world would you introduce that potential black hole issue amidst the hurricanes taking place above? LOL! Just kidding! But seriously, if proper process is followed, the bed is already straight and therefore the test results purely relate to where the head points. But..... if as you suggest, if the bed is twisted in such a way that the test coupon becomes a perfect cylinder then I submit that everything cancels everything else, and the end results that the lathe produces works the way it should (produces a perfect cylinder), and we can get on with life. This is the outcome that

@thestelster achieved earlier by deliberately twisting his lathe bed. The guy is a genius if you ask me...... But of course we must also acknowledge that he got there in a very unconventional way that even he would probably have preferred to avoid.

For my part, I would only say that your hypothetical result depends on a faulty process since your result is founded on incorrectly aligning the bed before going to the next step with the collar bar. Like you, I confess that I cannot easily get my head around what it takes to get that result though. I think it's probably some form of Helical bed shape that maintains the spacial equidistance of both rails from the central axis of the spindle in a coordinate system that is referenced to the saddle. But frankly, that's about as much neural power as I want to invest in the question....... (Insert image of a disoriented big old crazy hairy abominal snowman who just got off of a suicidal circus ride).

A few other points.

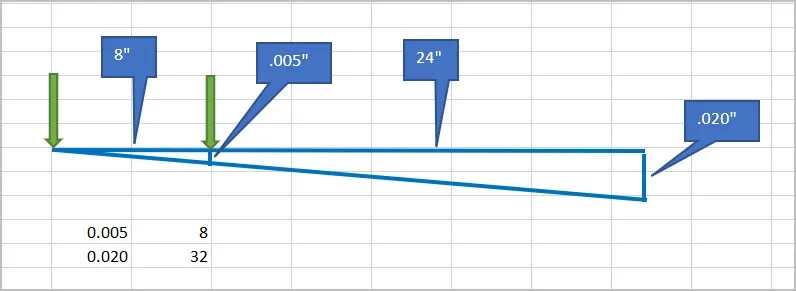

@PeterT - your analysis of the long coupon is exactly why I want to evaluate longer lengths. The longer the spacing, the better the resolution of the alignment measurement. Of course, there are two new problems that arise - bar droop due to gravity and deflection due to cutting forces. I have ideas about how to deal with those, but they require real world testing. I believe I can calculate them to some extent so I know roughly what they should be. But the variables are such that I think it requires real world calibration testing to be reliable enough to satisfy the intended purpose. That discussion belongs over in my other thread.