@PeterT - I apologize for my attempt at humour. I get myself in trouble that way all the time.

You made me laugh by suggesting that someone like me with an entire career in R&D didn't understand eliminating variables in an experiment. I simply couldn't resist throwing it back at you. But it seems to have degenerated into an argument. I'm sorry for that. It was not my intent.

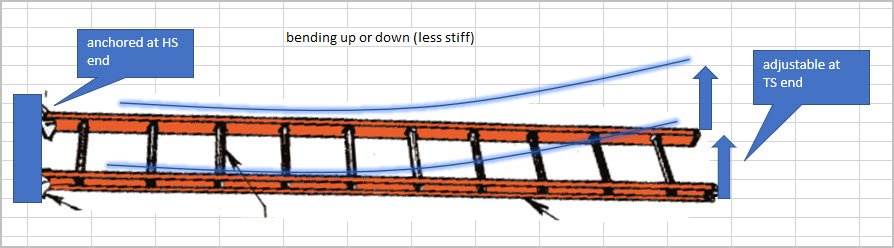

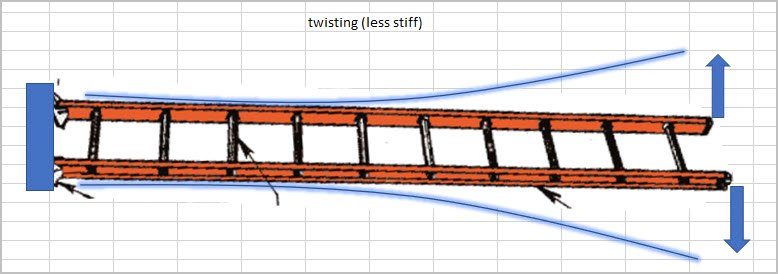

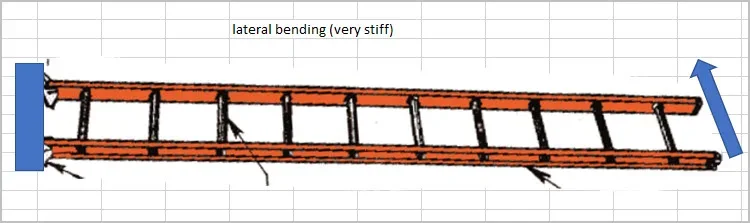

The problem with assuming that the head/spindle is in perfect alignment with the bed is that this scenario cannot reasonably produce a reading that high. The moment of area (stiffness) of your ladder is simply too great to allow it to bend that much - especially not in the fore aft direction. There has to be another explanation.

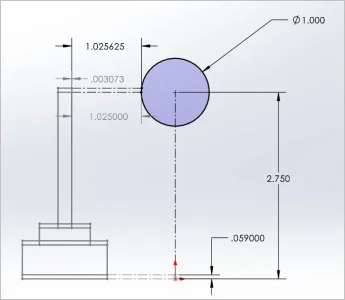

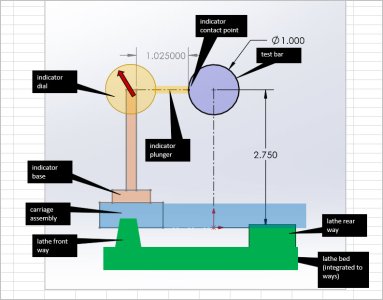

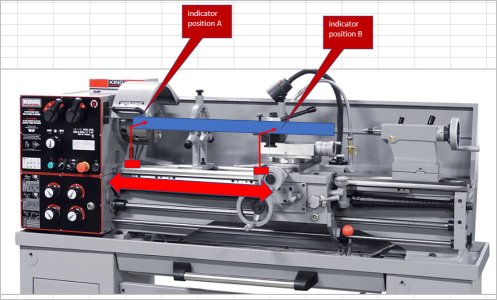

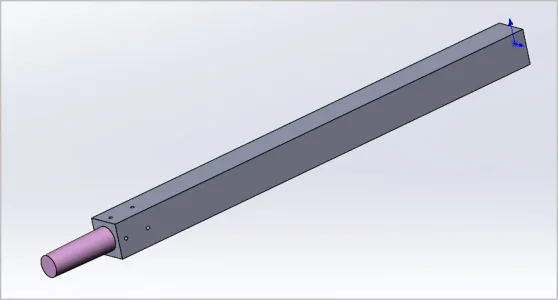

In your last reply, you refer back to the OPs question. So I'm no longer sure where you are really going with this question of yours. In the OPs case, we know the answer now. The bar that was being used to extend the axis of rotation was not concentric with the axis of rotation. After carefully reseating the test bar, much more reasonable results were obtained because the bar was now more closely aligned with the axis. That doesn't mean there is no misalignment - just that the misalignment is more reasonable. Also, I expect that a visit with Rudy to test the bar with a hands on explanation of what is going on will be of great benefit to Craig.

So I think that leaves only your hypothetical question which sticks to the original assumption of a perfect head bed alignment and asks what bed movement could produce such a relatively huge reading.

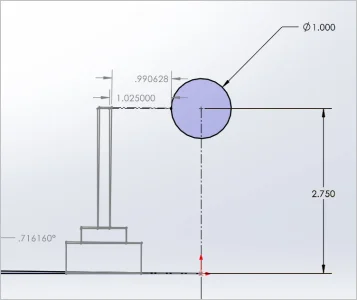

One answer (albeit quite unreasonable) is that the bed is bent in the horizontal plane away from the operator - like a curved railroad track on flat ground. It could also be warped up or down at the right as some of your examples show, but neither of those will move the needle that much without visible obvious twisting that would be obvious to the naked eye. Your drawings show that just fine and I believe that your simple math on that is correct.

So ya, how about a curved railroad track on flat ground......

I confess that I am reluctant to throw that out there because I know someone is gunna read that without the context and say something like "Are you crazy? No bed could ever bend like that!" And I would totally agree with them, and so would you. Nonetheless, given your assumptions it's the best answer I have. Change the assumptions and a perfectly reasonable answer pops out - the head is misaligned with the bed.

You made me laugh by suggesting that someone like me with an entire career in R&D didn't understand eliminating variables in an experiment. I simply couldn't resist throwing it back at you. But it seems to have degenerated into an argument. I'm sorry for that. It was not my intent.

The problem with assuming that the head/spindle is in perfect alignment with the bed is that this scenario cannot reasonably produce a reading that high. The moment of area (stiffness) of your ladder is simply too great to allow it to bend that much - especially not in the fore aft direction. There has to be another explanation.

In your last reply, you refer back to the OPs question. So I'm no longer sure where you are really going with this question of yours. In the OPs case, we know the answer now. The bar that was being used to extend the axis of rotation was not concentric with the axis of rotation. After carefully reseating the test bar, much more reasonable results were obtained because the bar was now more closely aligned with the axis. That doesn't mean there is no misalignment - just that the misalignment is more reasonable. Also, I expect that a visit with Rudy to test the bar with a hands on explanation of what is going on will be of great benefit to Craig.

So I think that leaves only your hypothetical question which sticks to the original assumption of a perfect head bed alignment and asks what bed movement could produce such a relatively huge reading.

One answer (albeit quite unreasonable) is that the bed is bent in the horizontal plane away from the operator - like a curved railroad track on flat ground. It could also be warped up or down at the right as some of your examples show, but neither of those will move the needle that much without visible obvious twisting that would be obvious to the naked eye. Your drawings show that just fine and I believe that your simple math on that is correct.

So ya, how about a curved railroad track on flat ground......

I confess that I am reluctant to throw that out there because I know someone is gunna read that without the context and say something like "Are you crazy? No bed could ever bend like that!" And I would totally agree with them, and so would you. Nonetheless, given your assumptions it's the best answer I have. Change the assumptions and a perfectly reasonable answer pops out - the head is misaligned with the bed.

Last edited: