Dan Dubeau

Ultra Member

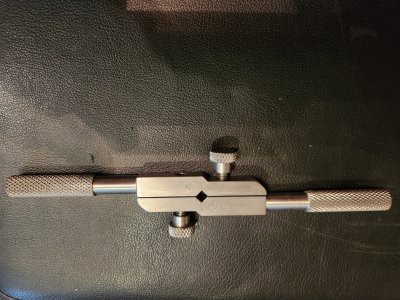

Also finished the contact wheel snap ring groove, and the tracking wheel axle.

Machined the bought wheel to length, then measure how close i got the bearing bore depths between the two.

Not bad, for the hokiest setup for depth control ive done yet....

The axel was made from a large fhcs

Thats all for today.....

Machined the bought wheel to length, then measure how close i got the bearing bore depths between the two.

Not bad, for the hokiest setup for depth control ive done yet....

The axel was made from a large fhcs

Thats all for today.....