TorontoBuilder

Sapientia et Doctrina Stabilitas

So back to the grind...

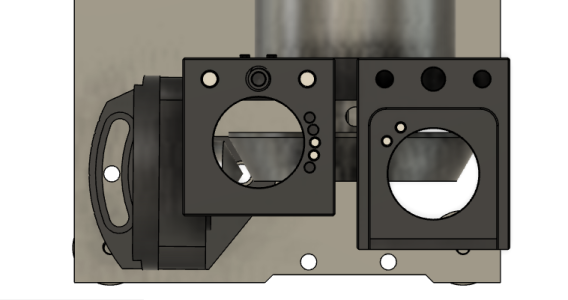

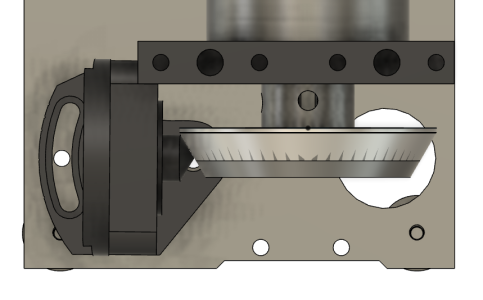

The 20G wheel being 33% thicker allows wider bits to be ground, but pushes the axis of the grinding seat outward from the grinding wheel. In the image below the pointed rod is 14mm diameter.

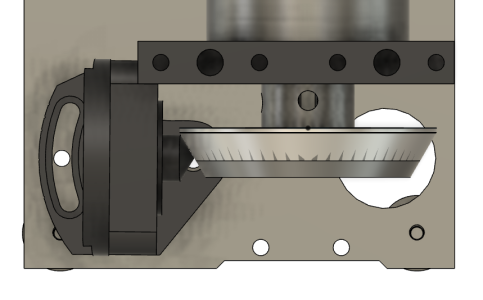

So, options to handle a 20G wheel. Machine new motor hub that sits a further 3 mm onto the motor shaft, and new A and B tool blocks for the 20G wheel, and make a 20G tool setter to provide the additional projection on the bit that will be required.

Or make a new dedicated 20G machine. I'll design blocks in either case.

The 20G wheel being 33% thicker allows wider bits to be ground, but pushes the axis of the grinding seat outward from the grinding wheel. In the image below the pointed rod is 14mm diameter.

So, options to handle a 20G wheel. Machine new motor hub that sits a further 3 mm onto the motor shaft, and new A and B tool blocks for the 20G wheel, and make a 20G tool setter to provide the additional projection on the bit that will be required.

Or make a new dedicated 20G machine. I'll design blocks in either case.