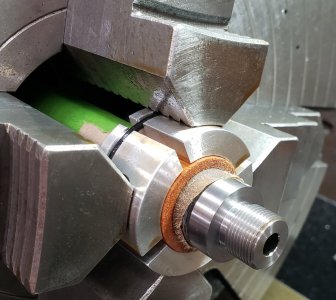

Today I needed to accurately and precisely drill and ream two holes, which for a number of reasons, I was only able to use a transfer punch. The operation in question was to install dowel pins as anti-rotation pins for my Multifix QCTP.

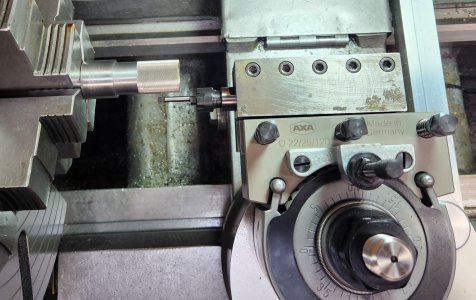

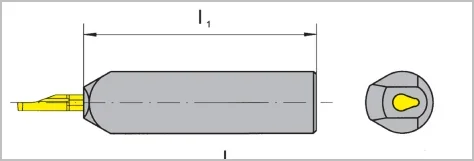

I used an edge finder with the pointed tip down, spindle NOT rotating, and held in the collet chuck. I lowered the quill gently until the point entered the punch mark. As you can see there was a displacement of the tip section from the main body of the edge finder. Using your fingers to feel, you moved the table until it felt as one. I the put the micrometer at the joint and used a back light to see the gap. Moved the table until the gap was gone. Do it in both axis. I've never done this before so I was happier than a pig in poop, when the Multifix barrel slid on perfectly with no effort, and with no perceptible movement.

I used an edge finder with the pointed tip down, spindle NOT rotating, and held in the collet chuck. I lowered the quill gently until the point entered the punch mark. As you can see there was a displacement of the tip section from the main body of the edge finder. Using your fingers to feel, you moved the table until it felt as one. I the put the micrometer at the joint and used a back light to see the gap. Moved the table until the gap was gone. Do it in both axis. I've never done this before so I was happier than a pig in poop, when the Multifix barrel slid on perfectly with no effort, and with no perceptible movement.