-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Move is on - Stairs and 3 tons

- Thread starter Dabbler

- Start date

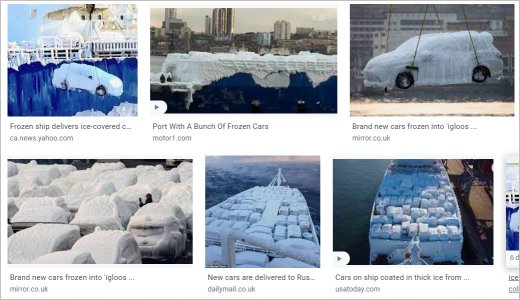

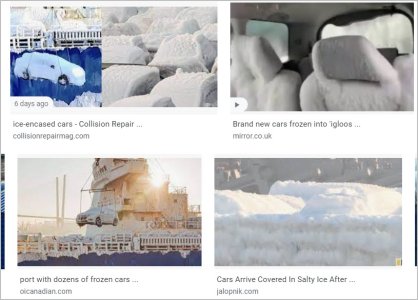

Those photos are hilarious!

Actually, there is a sticky plastic film that is used in transport @PeterT . But it is mostly a protectant for scratches not for corrosion protection. Automobiles are designed with very high levels of corrosion protection built right in. They can easily handle a transoceanic voyage or three.

Again, I'm not advocating it but that shrink wrap they use on pleasure boats for the winter might be a consideration when there are no other options and when used with other products. And thinkinf about this reminds me of the potential to use a VCI protectant like that found in parts containers where corrosion has been a problem. The VCI is soaked into cardboard and even paper and put in the box with the parts. The VCI slowly volatalizes and finds its way into the microscopic cracks in the grain structure of the metal to prevent corrosion from starting. It's very effective. I'm still looking for a bulk supply of the liquid.

And that reminds me that WD40 is selling a new (to me anyway) product called Corrosion Inhibitor. The label says it contains a VCI and is good for 1 to 2 years indoors. I bought a can of it to try but have not done so yet. Not sure what they claim outdoors.

www.wd40.com

www.wd40.com

Actually, there is a sticky plastic film that is used in transport @PeterT . But it is mostly a protectant for scratches not for corrosion protection. Automobiles are designed with very high levels of corrosion protection built right in. They can easily handle a transoceanic voyage or three.

Again, I'm not advocating it but that shrink wrap they use on pleasure boats for the winter might be a consideration when there are no other options and when used with other products. And thinkinf about this reminds me of the potential to use a VCI protectant like that found in parts containers where corrosion has been a problem. The VCI is soaked into cardboard and even paper and put in the box with the parts. The VCI slowly volatalizes and finds its way into the microscopic cracks in the grain structure of the metal to prevent corrosion from starting. It's very effective. I'm still looking for a bulk supply of the liquid.

And that reminds me that WD40 is selling a new (to me anyway) product called Corrosion Inhibitor. The label says it contains a VCI and is good for 1 to 2 years indoors. I bought a can of it to try but have not done so yet. Not sure what they claim outdoors.

Corrosion Inhibitors for Metal | WD-40 Corrosion Inhibitor | WD-40

The WD-40 Specialist Long-Term Corrosion Inhibitor protect metal parts from rust and corrosion for up to one year or two years indoors. Employ preventative maintenance with corrosion inhibitors for steel, metal, tools, engines and other parts.

Last edited:

LRSbm146

Member

I see this is an older thread.... those basement moves are terrible. We moved these 2 machines out of a Calgary basement around the Same time, January 2020

How about a write up on how you accomplished the move? Pics would be nice

LRSbm146

Member

@Dabbler I bought the lathe and it was getting moved to Leduc. The mill went to a friends house in Calgary. I was having trouble getting help lined up from Edmonton so hired movers off Kijiji. I showed up early and drained the oil, pulled the tailstock, carriage, chuck and had it off the stand and on the floor. The previous owner strongly recommended not going any further. Movers came, we stood it on end on a heavy duty dolly and out it went. Couple of tense moments on the stairs when the dolly gave out otherwise pretty smooth. The movers agreed to $600 delivered, I gave them $700 and a case of beer. They refused to have anything to do with the milling machine. Hahaha

The mill was moved in small as possible pcs over a couple weeks, 2 guys and a new dolly until it was just the base. New movers were hired, I think 6 guys showed up. It was not good. Pretty sure the stairs and back landing of the house need major repairs and the back door frame was damaged pretty bad.

The mill was moved in small as possible pcs over a couple weeks, 2 guys and a new dolly until it was just the base. New movers were hired, I think 6 guys showed up. It was not good. Pretty sure the stairs and back landing of the house need major repairs and the back door frame was damaged pretty bad.

Attachments

I think 6 guys showed up. It was not good.

Fortunately our move went a little more smoothly....

We protected the stairs by making a track using 2 - 2X8s on their side, and everything was strapped down to a custom dolly. We used the hotshot winch on a car hauler that I hired for 600$ to do the lifting. No one was in the fall line as things went up. Well the previous owner kept walking into it and needed shooing away.

The bull noses on the stairs got a few nicks, and we put a tiny ding in the drywall that took 5 minutes to fix.

The lathe bed was too dangerous to lift that way, as it was too long to negotiate the turn at the top of the stairs. I make a custom crane cradle between the floor joists and moved it out the window with that. It weighed 975 lbs, about the same weight as the milling machine base.

I had to buy and/or make 7 or 8 dollies, a dozen or more heavy winch straps, lumber for the cradle, and the metal makings of the joist crane, a new main beam for my gantry crane, a 1 ton scale, tarps, some tools, cribbing, plywood to protect the landing, and the wood to make a deck outside his back door to recieve all the machine tools. We did 16 lifts that day, and moved the lathe bed later.

FWIW we called Prime movers, and they wouldn't move a bridegport type mill out of the basement. It was too dangerous for their crew. tHEY wanted just under 10K$ to move the lathe out of the basement. That was the incentive for doing it 'homebrew'.

FWIW we called Prime movers, and they wouldn't move a bridegport type mill out of the basement. It was too dangerous for their crew. tHEY wanted just under 10K$ to move the lathe out of the basement. That was the incentive for doing it 'homebrew'.

LRSbm146

Member

@Dabbler the movers for the lathe were really good, the guys for the mill were pretty sketchy and didn’t want help.

Sean, the old timer that We bought the machines from was really good about everything. He sat, drank his tea and didn’t say much.

The house everything was in was being sold as well and the new owner was there, he informed us the house was getting a full reno. So all was good in the end.

Sean, the old timer that We bought the machines from was really good about everything. He sat, drank his tea and didn’t say much.

The house everything was in was being sold as well and the new owner was there, he informed us the house was getting a full reno. So all was good in the end.

Former Member

Guest

Here is something you wish you had, I've used one in the early 90's. Makes you look like superman. They work extemely well just don't mix up the sequence of operation or you loss the load.

www.powermate.info

www.powermate.info

Stair Climbing Hand Truck | PowerMate Stair Climber

The PowerMate stair climber hand truck is the world's finest two wheel dolly with stair climbing capability. Interior vehicle Lift Gates and Lift tables

We tried to rent one - but the only one taht we could get wouldn't make the turn at the top of the stairs (and it would have cost double what we paid for the truck/winch)

I think it's amazing that the stairs didn't collapse. Most of those stairway stringers end up being a 2x4 by the time the steps are cut into them. I've even seen pre-cut stringers made from 2x4s with step risers tacked to them. Two 2x4s don't carry a lot of weight.

I MUCH prefer @Dabbler s approach to custom carriers that spread the weight out.

Still a risky operation no matter what you do.

If I was faced with moving a basement full of heavy machines, I would have considered excavating and opening up a basement wall, and booming the equipment out. I know its not practical in every case, but putting a basement wall back together and backfilling a hole is quick and easy compared to tearing down multiple precision machines with hundreds of parts. Just offering a different approach.

If I was faced with moving a basement full of heavy machines, I would have considered excavating and opening up a basement wall, and booming the equipment out. I know its not practical in every case, but putting a basement wall back together and backfilling a hole is quick and easy compared to tearing down multiple precision machines with hundreds of parts. Just offering a different approach.

I agree totally. It was my first thought actually. But unfortunately, very few sellers would allow that.

If I had to put my own shop in the basement, I would put in an enclosed oversized grade entrance with a removeable wall. It would be relatively low cost compared to the flexibility it would give me in the years to come for upgrades, additions, and sales.