pdentrem

Ultra Member

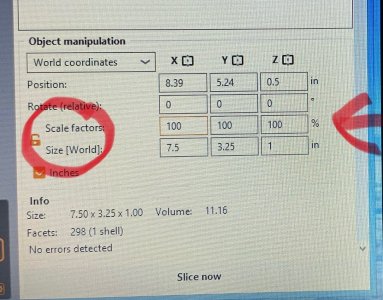

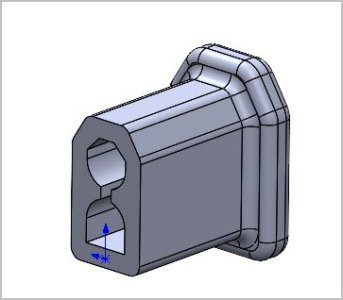

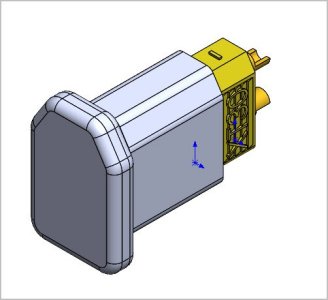

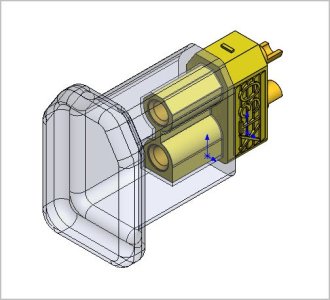

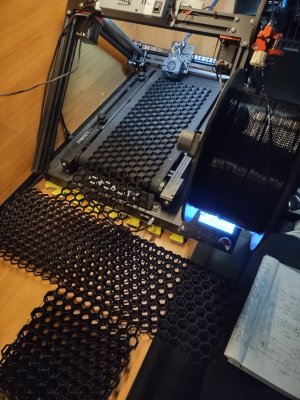

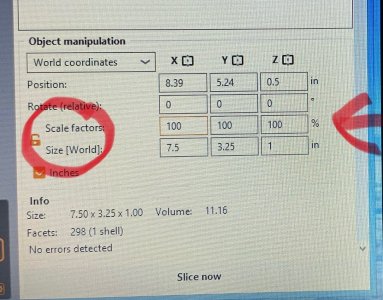

Here is a summary of the Ryan’s boxes I printed. I did print multiple copies of all of these. One can see that they are of different sizes as needed to fit the wild section of taps in my poor collection. Trays like this are very flexible in being able to resize. I included a screen shot of the area on the main screen of Prusaslicer. One unlocks the Scale Factors and you can either the percentages in X,Y, and Z or directly type in the dimensions you want in the respective boxes. I imagine that the other slicer programs have the equivalent controls.

Pierre

Pierre